Modernist

Established Member

The fruits of my momentary weakness arrived today, packed to the nines as is customary. Fortunately being a 6 the wooden box potentially has some uses but the goods were certainly well protected for their journey.

Having wiped off the protective goo I thought I'd test the oft mentioned "out of the box" theory and set about a piece of Brazilan Mahogany which was still on the bench after a species check with Mr Grim (he's human :lol: ).

To my surprise it was fine producing a stream of even shavings and a satisfying hiss. As with the recent block plane the new grinding did impart a certain directional pull but I am sure this will quickly wear off.

The tote was the customary grasswood or whatever it's called but, whilst not in the patina'd cherry class, is quite serviceable. It's tempting to make some new in cherry for the full experience.

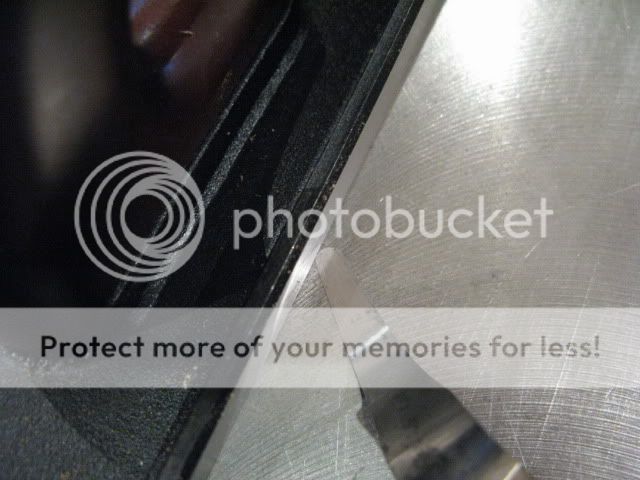

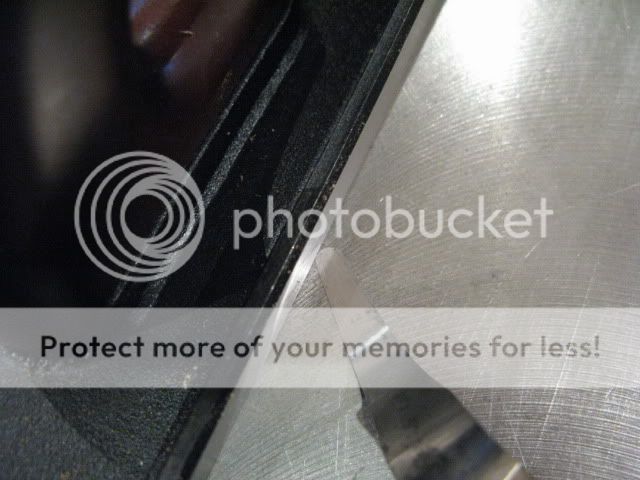

I next checked for squareness and quality of grinding. Appearance was excellent and grinding fine and I could see no error in the squareness around the mouth but a slight slick of light squeezed under one side of the square at the rear.

I cleaned up the tables on the Hammer and tried the plane against this surface. Although I could detect no rocking I could just ease a 3 thou feeler under the back corner - not the end of the world. I than sat down with a cup of tea to consider my purchase. Finishing the tea I tried it again and was delighted to note that it was now as flat as I could measure.

I tried the saw table and different positions in case the tables were a bit out but couldn't get a 3 thou feeler under anywhere. (I,.d snapped my 1 1/2 thou blade so could test for that.

I can only put this down to the fact that the plane was freezing when unpacked and had warmed up to room temperature for the second test. I think that'll do for me - well done Quangsheng and WSH.

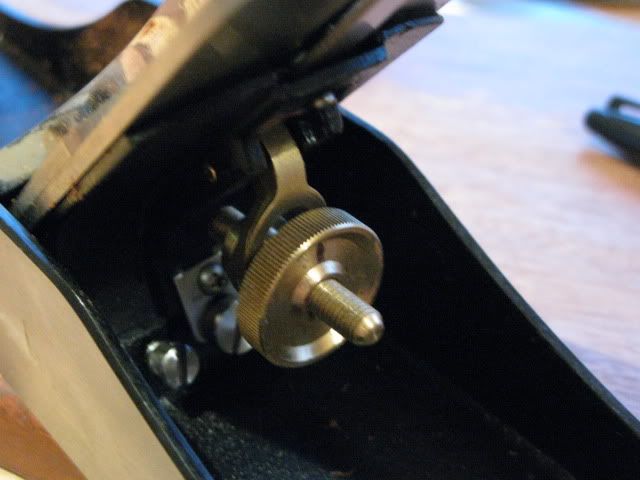

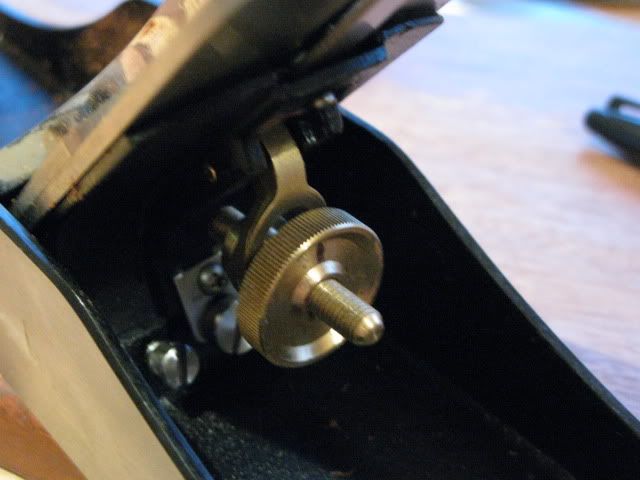

The bedrock frog adjustment was tested and worked smoothly, closing the mouth up to zero if required. Despite the comments to the contrary I remain a believer in just cleaning up the front surface of the mouth. It can't do any harm can it?

Finally we come to the blade adjustment which was the only critical point about the block plane. It works smoothly enough but there are a full 1 1/2 turns between motion fore and back.

I don't think this is any big deal. After all there is 3/4 of a turn on my LN 4 1/2 and just how much of our lives do we spend spinning the adjuster to and fro?

I have not fully prepared the blade/cap iron yet but a quick touch on the stone indicates the steel is similar to that of the block plane i.e. quite easy to hone and taking a fine edge quite quickly. Edge holding will have to be establish on a more long term test so I will report back in due course.

Once again this is a quality tool, not in the big 3 class, but close enough to give their marketing departments a major headache. Like others I was suprised by the quality at this price level and have no reservations in recommending it to others. Not having a 5 1/2 I am intending to use the 6 as a general joinery plane and I believe the extra length and weight will prove to be an advantage.

Having wiped off the protective goo I thought I'd test the oft mentioned "out of the box" theory and set about a piece of Brazilan Mahogany which was still on the bench after a species check with Mr Grim (he's human :lol: ).

To my surprise it was fine producing a stream of even shavings and a satisfying hiss. As with the recent block plane the new grinding did impart a certain directional pull but I am sure this will quickly wear off.

The tote was the customary grasswood or whatever it's called but, whilst not in the patina'd cherry class, is quite serviceable. It's tempting to make some new in cherry for the full experience.

I next checked for squareness and quality of grinding. Appearance was excellent and grinding fine and I could see no error in the squareness around the mouth but a slight slick of light squeezed under one side of the square at the rear.

I cleaned up the tables on the Hammer and tried the plane against this surface. Although I could detect no rocking I could just ease a 3 thou feeler under the back corner - not the end of the world. I than sat down with a cup of tea to consider my purchase. Finishing the tea I tried it again and was delighted to note that it was now as flat as I could measure.

I tried the saw table and different positions in case the tables were a bit out but couldn't get a 3 thou feeler under anywhere. (I,.d snapped my 1 1/2 thou blade so could test for that.

I can only put this down to the fact that the plane was freezing when unpacked and had warmed up to room temperature for the second test. I think that'll do for me - well done Quangsheng and WSH.

The bedrock frog adjustment was tested and worked smoothly, closing the mouth up to zero if required. Despite the comments to the contrary I remain a believer in just cleaning up the front surface of the mouth. It can't do any harm can it?

Finally we come to the blade adjustment which was the only critical point about the block plane. It works smoothly enough but there are a full 1 1/2 turns between motion fore and back.

I don't think this is any big deal. After all there is 3/4 of a turn on my LN 4 1/2 and just how much of our lives do we spend spinning the adjuster to and fro?

I have not fully prepared the blade/cap iron yet but a quick touch on the stone indicates the steel is similar to that of the block plane i.e. quite easy to hone and taking a fine edge quite quickly. Edge holding will have to be establish on a more long term test so I will report back in due course.

Once again this is a quality tool, not in the big 3 class, but close enough to give their marketing departments a major headache. Like others I was suprised by the quality at this price level and have no reservations in recommending it to others. Not having a 5 1/2 I am intending to use the 6 as a general joinery plane and I believe the extra length and weight will prove to be an advantage.