Fromey

Established Member

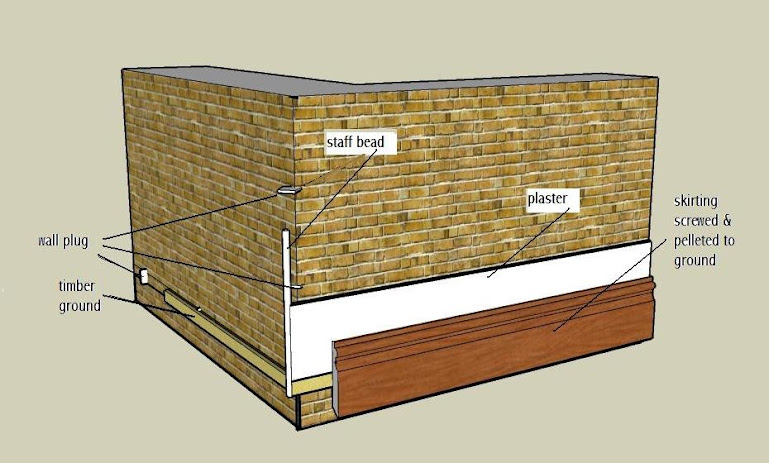

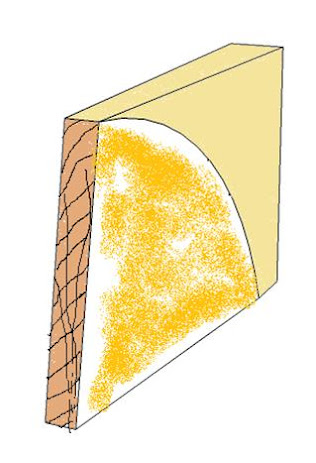

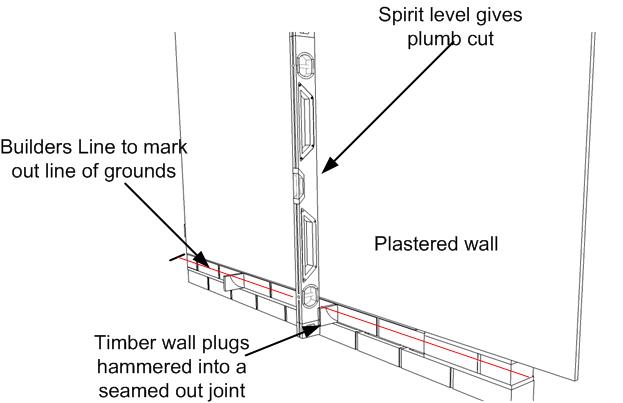

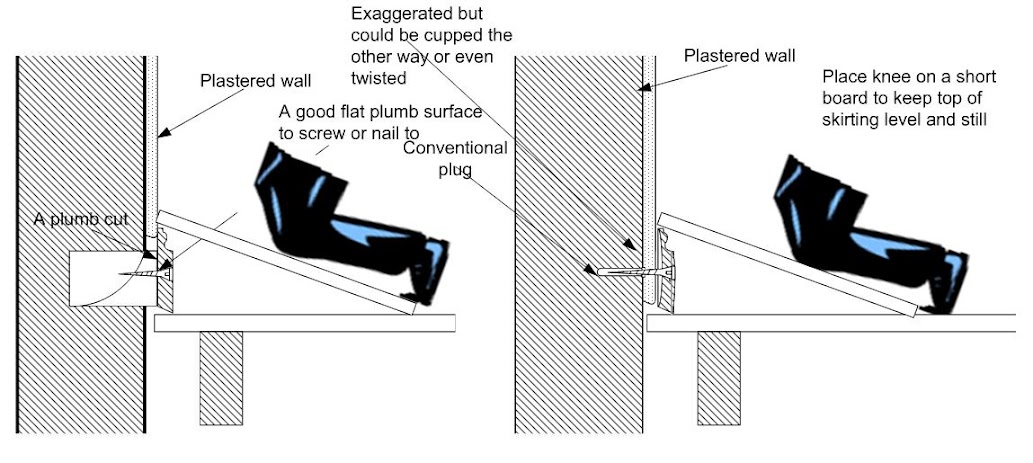

My house is about 1900 vintage and shows the typical palimpsest of past (usually incompetent) renovations. When it comes to the skirting boards there are two types of fixings. The modern bang a hardened nail into the brick at any convenient location and the more traditional bore holes in the wall, ram in wooden dowels and then nail the skirting into the dowels. (I'm assuming the latter is the traditional way as the dowels and nails I've dug out are always ancient looking.)

Although the traditional way is a lot more work, I'd like to install some new skirting in this manner for the traditional value of it plus the nails don't appear to rust like they do when driven straight into the brick (we have a reasonable amount of rising damp).

However, I'm stumped as to how they did this so accurately (granted you can see where sometimes they didn't get the nail quite so aligned). I'm sure there is some traditional trick to this and am wondering if anyone here knows the lore.

Thanks in advance.

Although the traditional way is a lot more work, I'd like to install some new skirting in this manner for the traditional value of it plus the nails don't appear to rust like they do when driven straight into the brick (we have a reasonable amount of rising damp).

However, I'm stumped as to how they did this so accurately (granted you can see where sometimes they didn't get the nail quite so aligned). I'm sure there is some traditional trick to this and am wondering if anyone here knows the lore.

Thanks in advance.