MattRoberts

Established Member

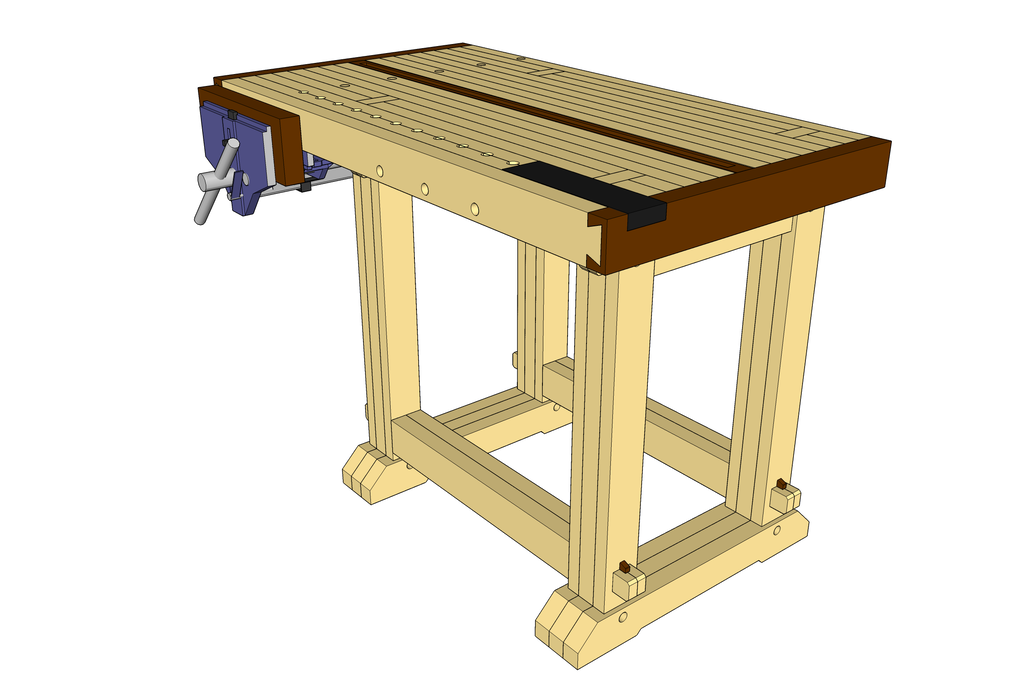

So finally I'm getting round to building my first workbench. I've decided to prototype it first, as I really don't know what sort of workbench I need or what configuration will work for me best. I also want to build one from decent wood in the future, so I'd rather build a prototype from cheap wood before splashing out on something better quality.

It's essentially a split-top Roubo, using a Record 52 1/2 vice along with a Veritas tail vice. The central strip is a reversible plane stop / tool holder. I'm going to use CLS 38 x 89 for the prototype material, and I've designed the bench to use various 2 and 3 lamination components.

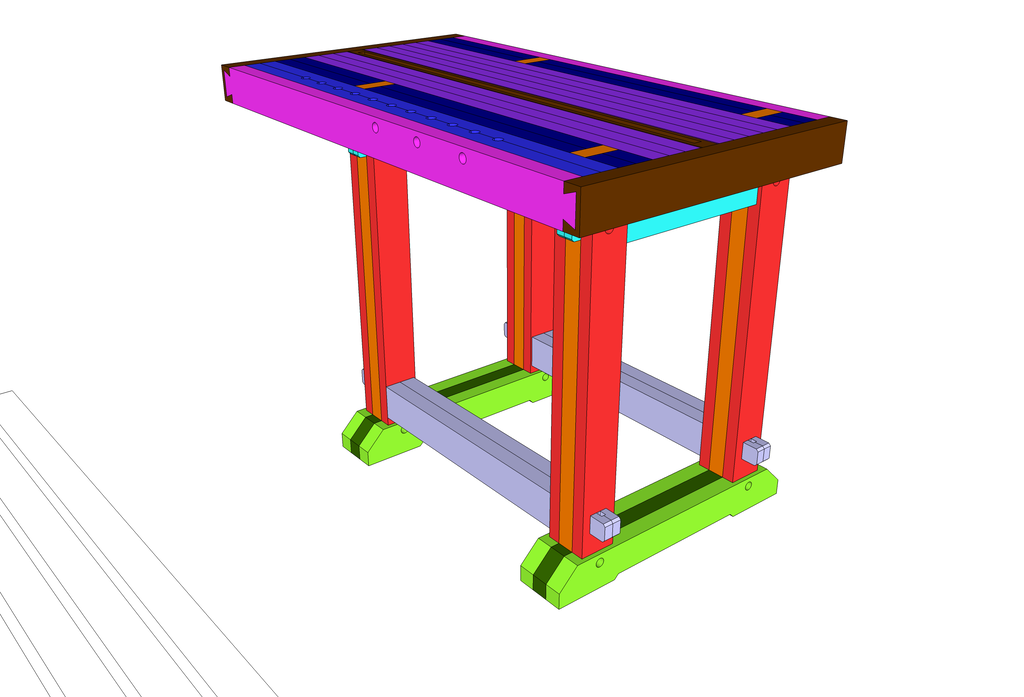

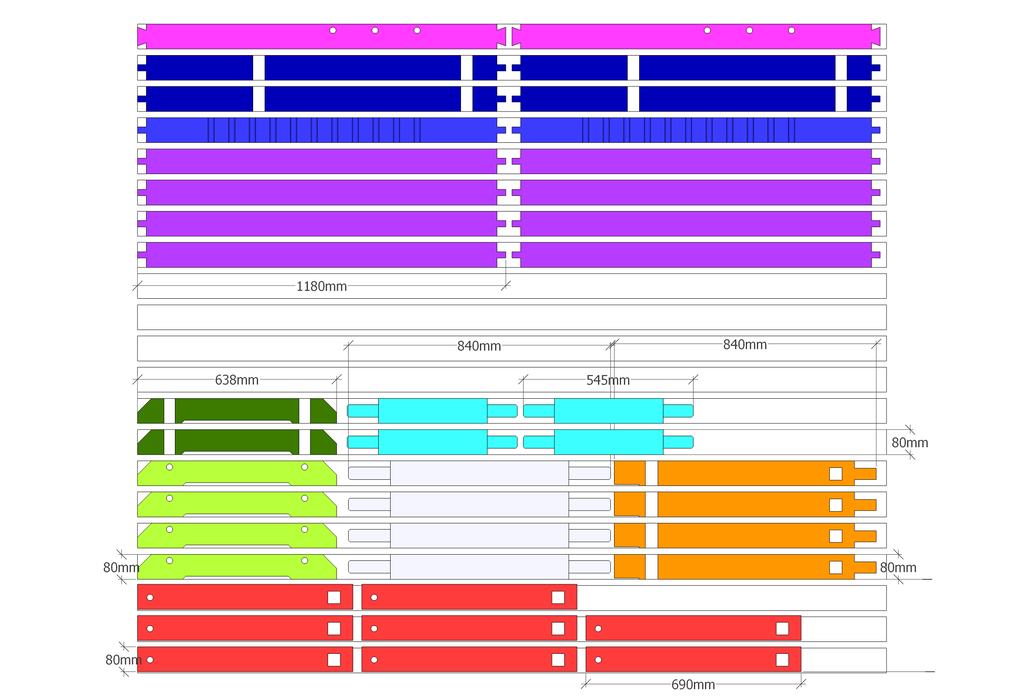

I like to colour code my sketchup models and then strip out the components into a cut list to make things easier.

I'd be interested to hear any thoughts or suggestions along the way

It's essentially a split-top Roubo, using a Record 52 1/2 vice along with a Veritas tail vice. The central strip is a reversible plane stop / tool holder. I'm going to use CLS 38 x 89 for the prototype material, and I've designed the bench to use various 2 and 3 lamination components.

I like to colour code my sketchup models and then strip out the components into a cut list to make things easier.

I'd be interested to hear any thoughts or suggestions along the way