Guys any idea what could be causing it to stop and start ?

https://1drv.ms/v/s!AoIHLHWc2o66baD4CxjG5sly_iA

I bought it years ago for my dad to use and after a year of him not using it I thought I'd use it. It kept starting and stopping which I put down to the unheated garage causing water inside to freeze and blowing all the seals.

I tried a softly softly disassemble and swapped the capacitor with an identical pressure washer I use for work- its 150% not a capacitor issue ;@) I cleared out my shed at the weekend and thought I'd go guns blazing at taking it apart. I was doing well until I noticed what looked like kettle scale on some of the metal components.

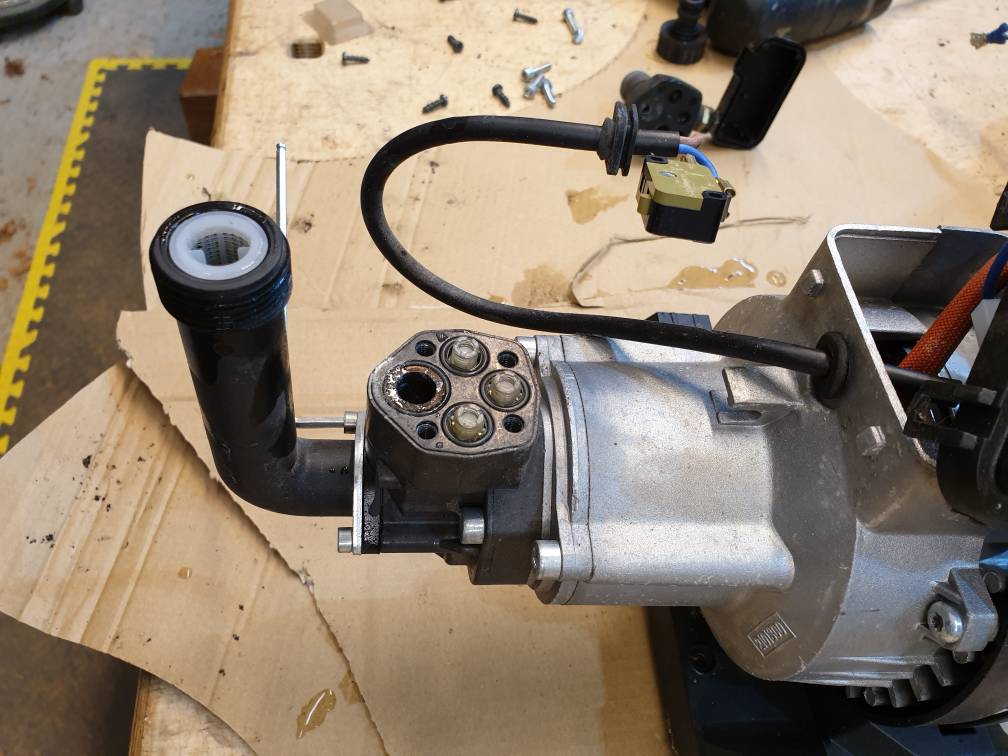

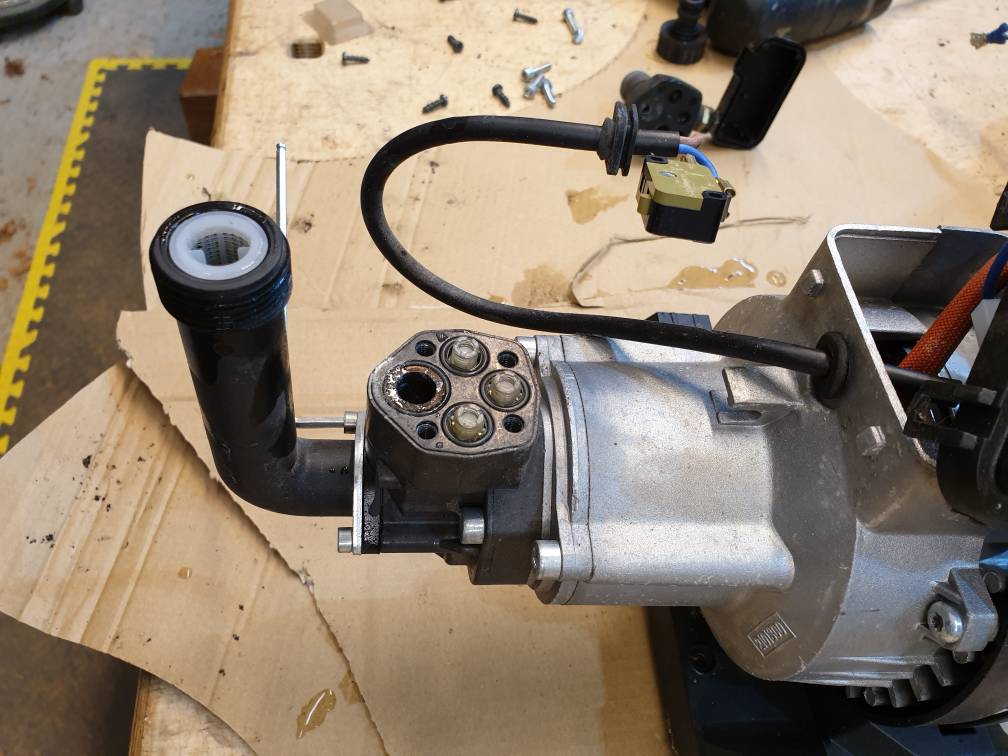

when I pushed the micro switch it caused these 3 piston things-

To run continuously. I started believing it could be fixed. I soaked the bits in white vinegar but nothing has changed.I don't need it but its began to niggle me again that perhaps it could be something simple. I couldn't quite figure out what causes the micro switch to become pressed- a demand of water/release from the gun ? Any ideas chaps?

Sent from my SM-G960F using Tapatalk

https://1drv.ms/v/s!AoIHLHWc2o66baD4CxjG5sly_iA

I bought it years ago for my dad to use and after a year of him not using it I thought I'd use it. It kept starting and stopping which I put down to the unheated garage causing water inside to freeze and blowing all the seals.

I tried a softly softly disassemble and swapped the capacitor with an identical pressure washer I use for work- its 150% not a capacitor issue ;@) I cleared out my shed at the weekend and thought I'd go guns blazing at taking it apart. I was doing well until I noticed what looked like kettle scale on some of the metal components.

when I pushed the micro switch it caused these 3 piston things-

To run continuously. I started believing it could be fixed. I soaked the bits in white vinegar but nothing has changed.I don't need it but its began to niggle me again that perhaps it could be something simple. I couldn't quite figure out what causes the micro switch to become pressed- a demand of water/release from the gun ? Any ideas chaps?

Sent from my SM-G960F using Tapatalk