Dr Al

Established Member

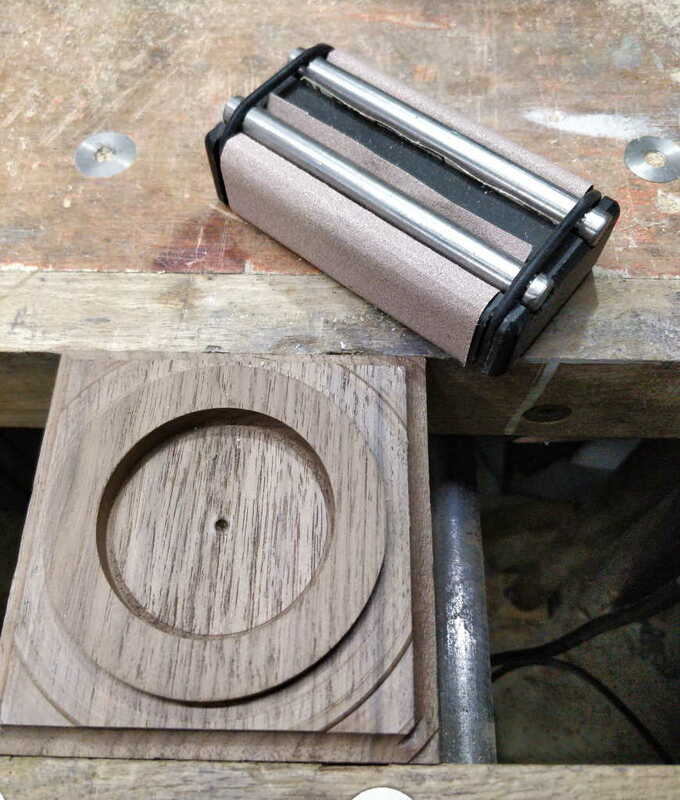

Next up was the jam bar. This one took a bit of thought!

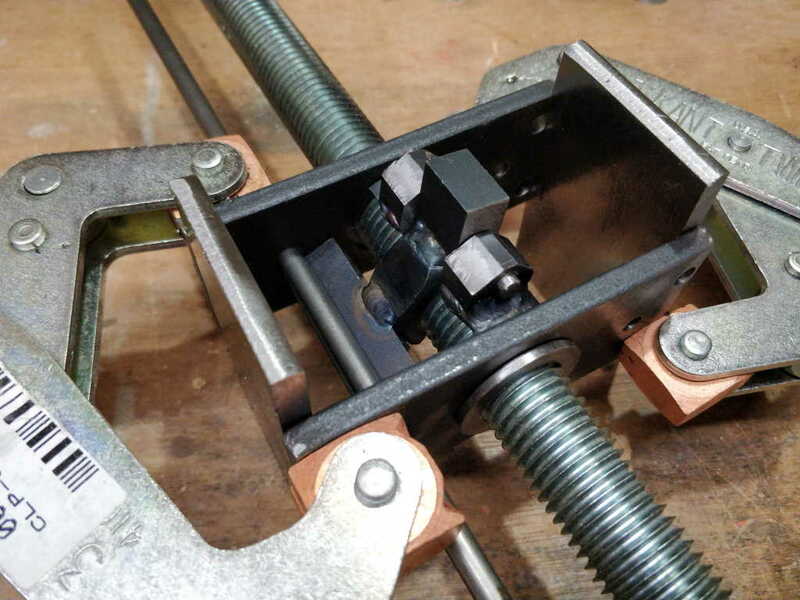

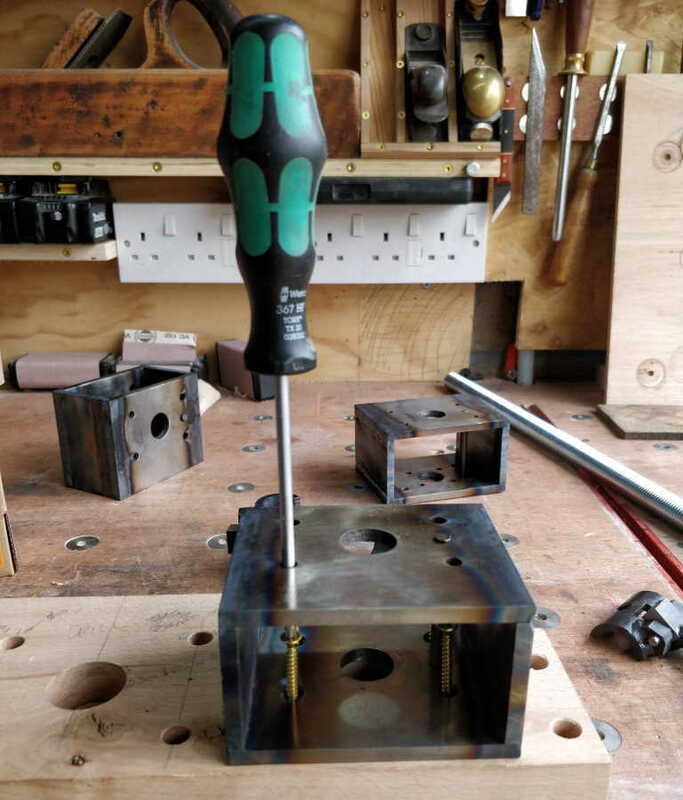

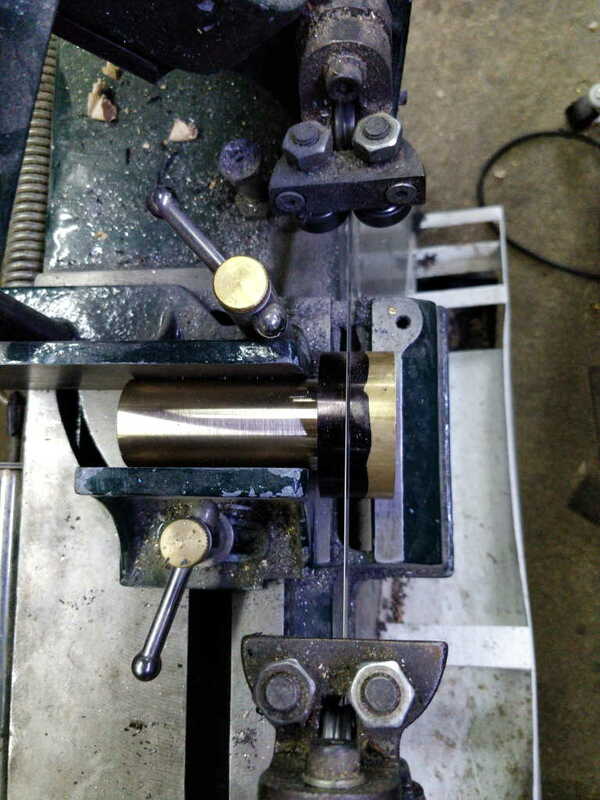

I started by digging out some bits of steel that were the right size to make sure the nut would sit in the middle of the jam bar. I clamped them in place using a spare half-nut as a spacer:

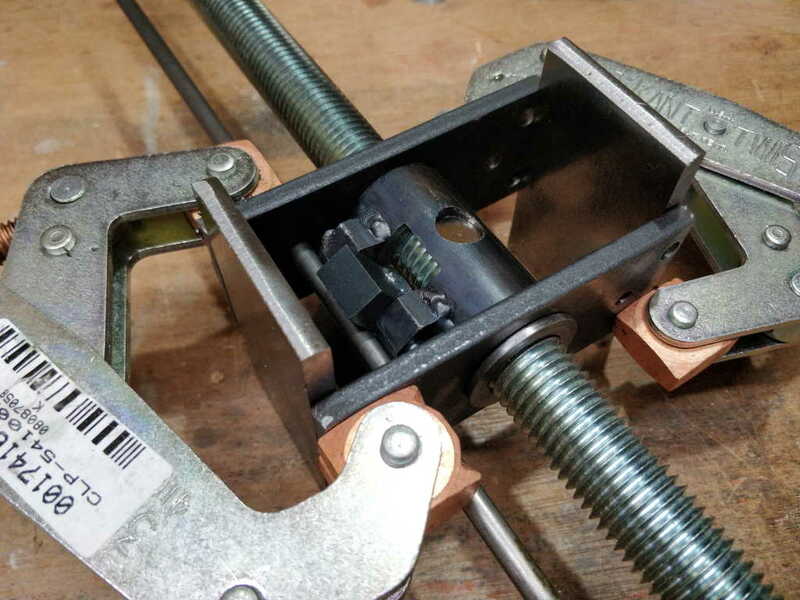

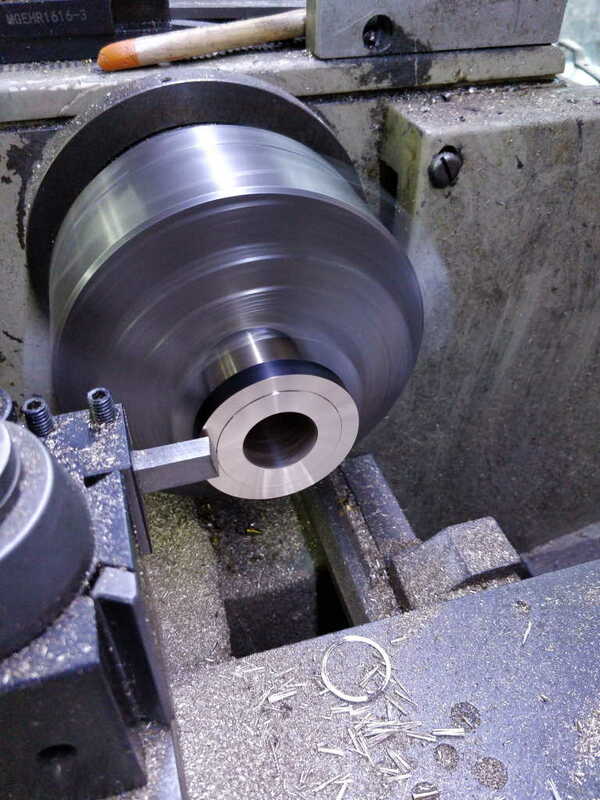

I could then fit the proper nut and clamp it in the right place:

The rest was easy. I was extra careful with the weld on the outer face as the jam shaft in the body may run near that and I didn't want it to get stuck on a sticky-out bit.

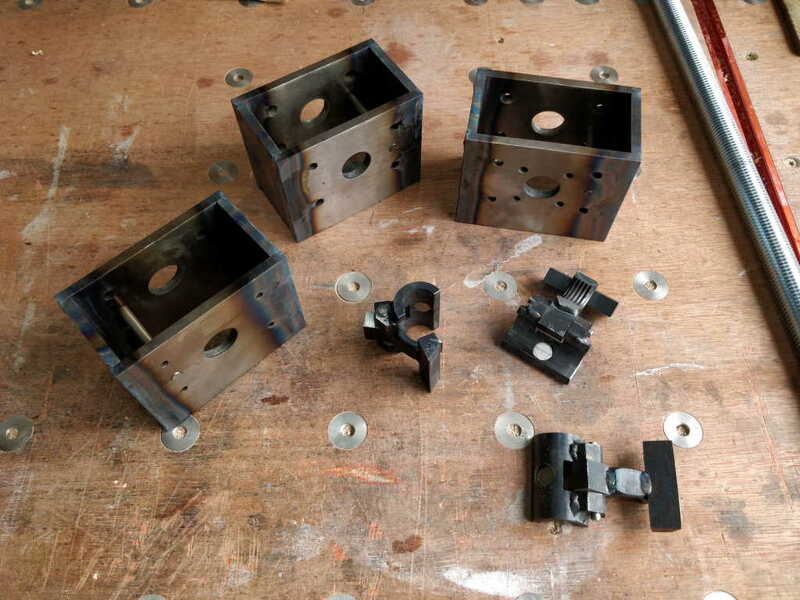

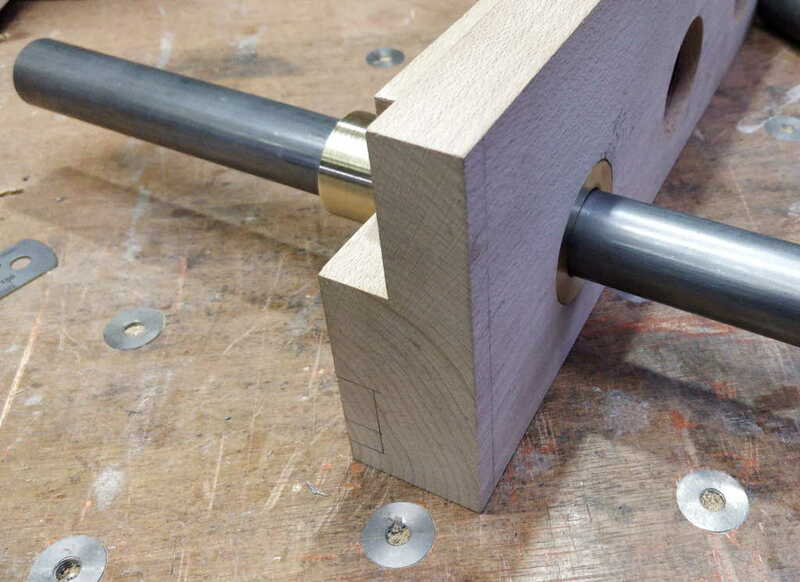

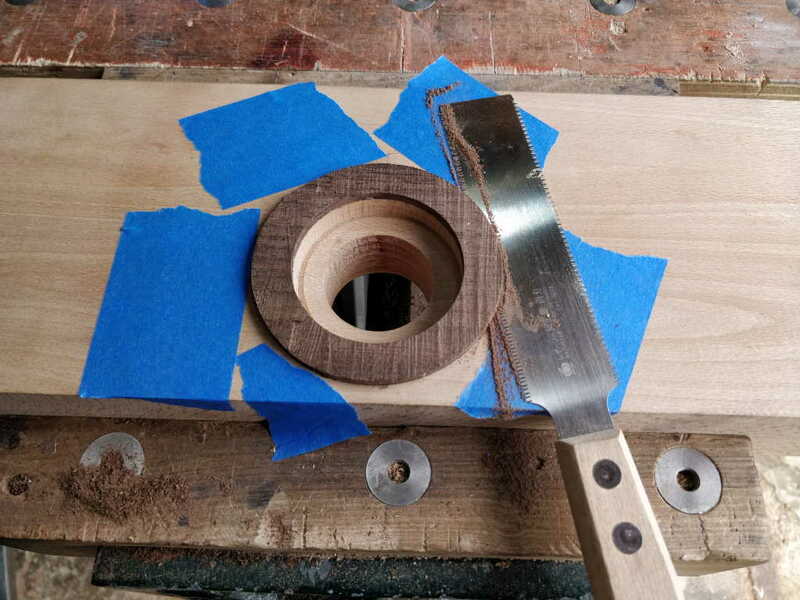

After letting everything cool down, I could put the two pieces together to mark up for the hinge. This is where I realised that I'd put the tube hinge blocks on the wrong way round! Thankfully the hinge hole is intended to be central, so I can just chamfer the other corner.

Before that, I marked up where the hole for the hinge will be:

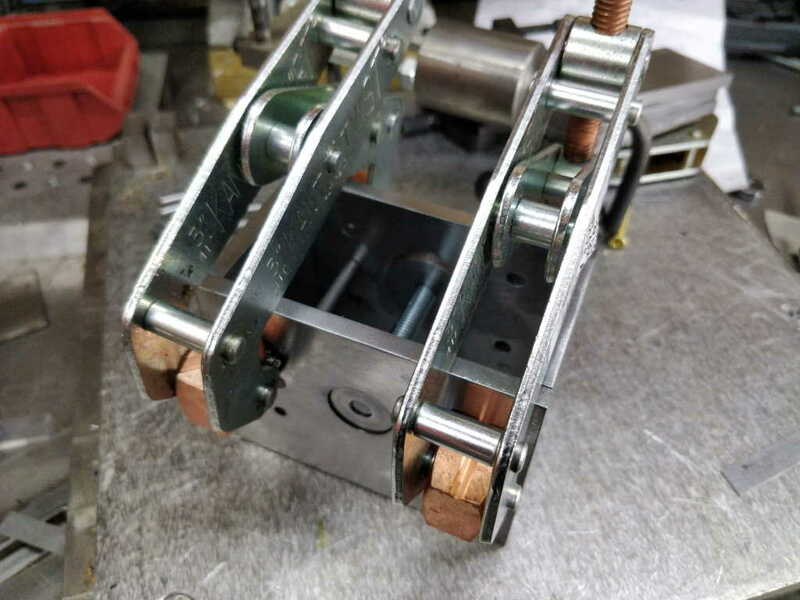

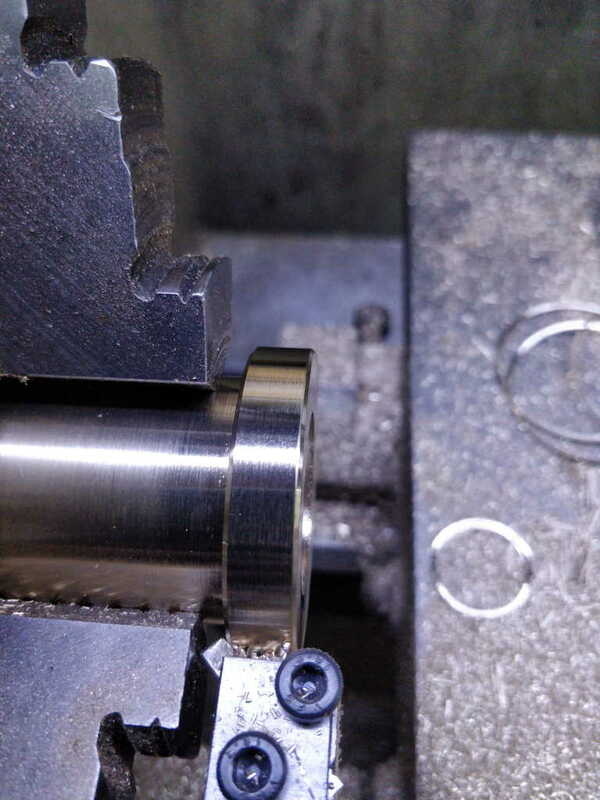

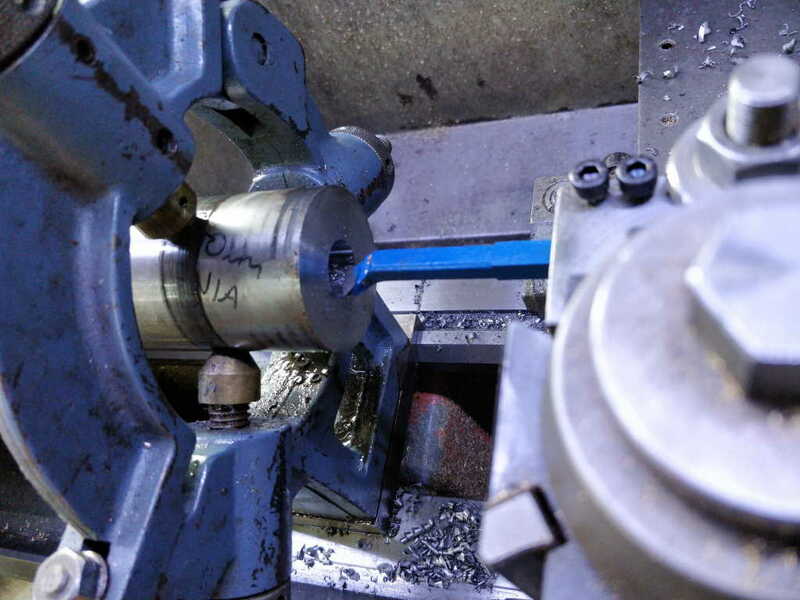

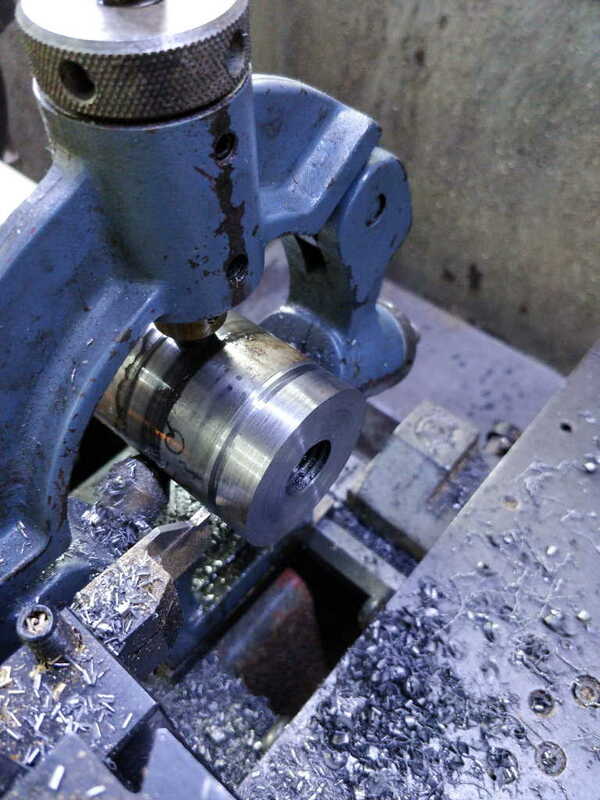

I then used a spare half-nut and a short length of threaded rod to clamp everything together in the milling vice:

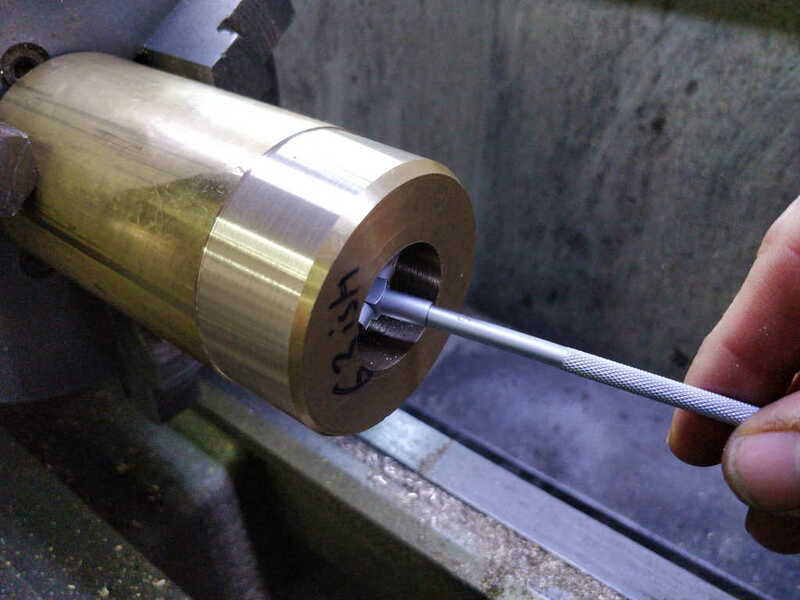

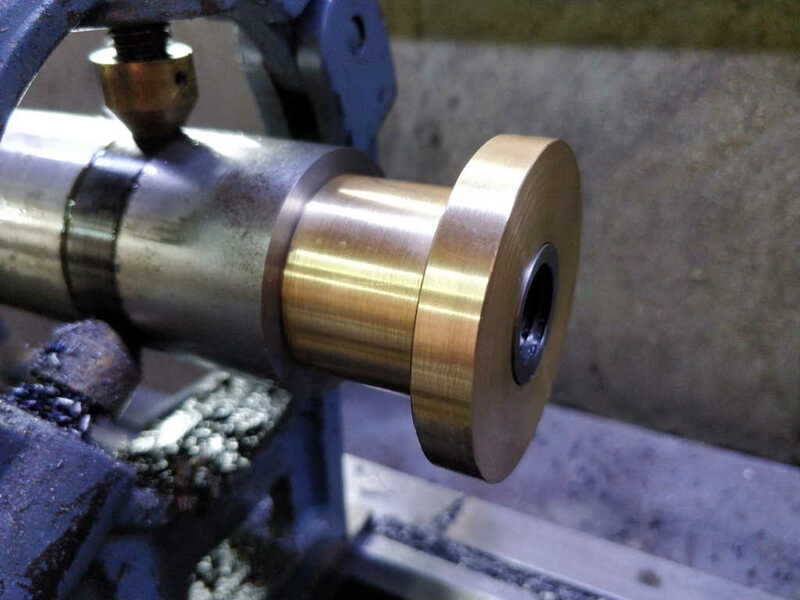

It was then fairly straightforward to spot drill and drill through the 5 mm hole for the hinge bar:

I started by digging out some bits of steel that were the right size to make sure the nut would sit in the middle of the jam bar. I clamped them in place using a spare half-nut as a spacer:

I could then fit the proper nut and clamp it in the right place:

The rest was easy. I was extra careful with the weld on the outer face as the jam shaft in the body may run near that and I didn't want it to get stuck on a sticky-out bit.

After letting everything cool down, I could put the two pieces together to mark up for the hinge. This is where I realised that I'd put the tube hinge blocks on the wrong way round! Thankfully the hinge hole is intended to be central, so I can just chamfer the other corner.

Before that, I marked up where the hole for the hinge will be:

I then used a spare half-nut and a short length of threaded rod to clamp everything together in the milling vice:

It was then fairly straightforward to spot drill and drill through the 5 mm hole for the hinge bar: