Joe

Established Member

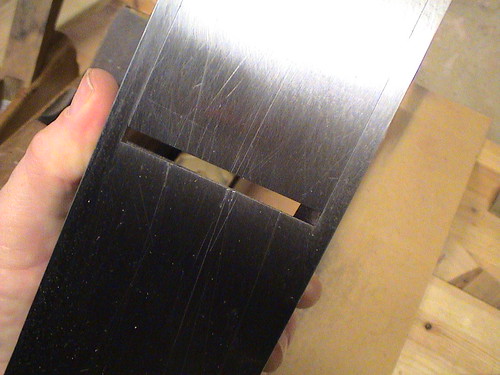

I'm recycling an old school table-top, cutting some 70mm x 20mm x 60mm boards out of it. The problem is that it seems to be shredding my plane iron - I can barely clean up a single face of the timber (which is fairly flat anyhow) before the blade's cutting edge appears minutely serrated and a wire-edge forms on the back. I started off with a 30 degree secondary bevel and 32 degree micro-bevel then increased both these angles by 5 degrees, but it doesn't seemed to have helped much (the blade is A2 steel). Is this normal, or am I doing something wrong?

If anyone can offer some advice it would be much appreciated!

If anyone can offer some advice it would be much appreciated!