Saintsman

Established Member

I'm making a couple of garden planters in Iroko: having run them through the thicknesser to just over size (using enough masks, filters and extractors to make Axminster's profit for the year) , I want to smooth them by hand.

OK so far, so reach for the LV BU jointer.

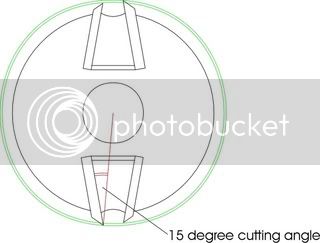

Question: a higher angle is recommended for difficult woods, yet on the John Boddy Timber website they suggest reducing the cutting angle to 15 degrees for a smooth finish due to the interlocked grain.

This could confuse a stupid person: I'm confused........

Should I try a higher or lower angle than normal, or sit on the fence and just use it as standard ?

Paul[/u]

OK so far, so reach for the LV BU jointer.

Question: a higher angle is recommended for difficult woods, yet on the John Boddy Timber website they suggest reducing the cutting angle to 15 degrees for a smooth finish due to the interlocked grain.

This could confuse a stupid person: I'm confused........

Should I try a higher or lower angle than normal, or sit on the fence and just use it as standard ?

Paul[/u]