Mr Ed

Established Member

I remember reading that post at the time, interesting, but it just doesn't do it for me - I'm obviously some sort of hammer heathen!

Ed

Ed

Aled Dafis":1z4e4sd2 said:Did you sneak a milling machine into the workshop without telling us Ed?

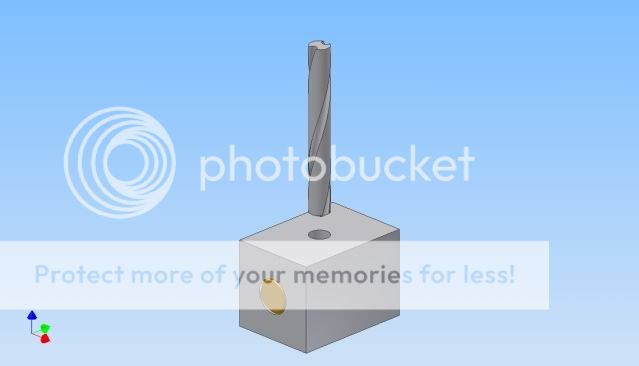

Harbo":1g3gqeuj said:Head from 32mm diam brass

Harbo":yauv49eq said:Mr Ed - you are probably right - it is a chisel hammer really.

Harbo":2q8gn20p said:January's F&C has David Barron "giving away" his production secrets on the short handled chisel hammer he sells.

Head from 32mm diam brass with round wedged hole - very easy to modify shape and size of handle if required?

Rod

wizer":1jjttbg3 said:Cheers Karl. Just got to work out how to do it. I'm thinking some sort of double screw that I can tap into the brass, somehow.

wizer":ta03tif7 said:I was thinking of using Goncalo Alves or Lignum.

Enter your email address to join: