As I mentioned briefly yesterday, I haven't been able to be out in the workshop for the last two days as often as I would have liked.

Yesterday began with a couple of hours on the planer - drawer rails, runners, muntins and centre posts and kickers.

I kept glancing over at my extractor bag, expecting it to fill up any minute but, I couldn't understand why this wasn't happening... Until I noticed the big hole in the side of the bag, leaving a pile of shavings all over this shelf and the floor behind!

(I'd already patched it up with duct tape by the time I took this shot.)

The outer stiles and centre posts needed a series of twin-mortises to receive the drawer rails. I did contemplate doing this

after the end frames had been assembled but, then decided this was clearly the sensible option!

Thanks to

several lapses in concentration on the mortiser, I accidentally chopped out this area at the top of each of the four stiles - this was a mistake; the top rail will be dovetailed in to here!

These mortises have since been filled with scraps of pine,

When cutting the twin-tenons, I first used the router table to get a nice, clean cut on the shoulders. Then, created two tenons on the bandsaw, like this, which left me with a little bit to be chopped out with a coping saw and chisel. Had I not made this smaller than 6mm then, yes, I could've done them on the mortiser... :roll:

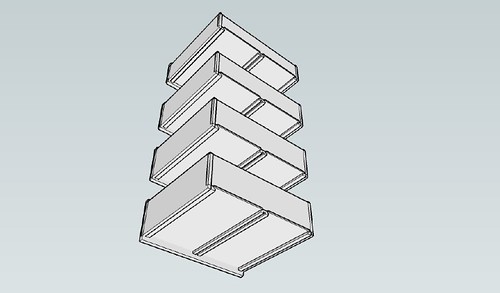

I did have time for a dry-run this afternoon and was able to take some measurements for the shoulder lengths on the runners and kickers. As you can see, this is another build which will press the limitations of space within my four-walled workshop!

It feels surprisingly sturdy, even without the cramps on. It's also fairly light weight, due mainly to the fact this is pine. Once those runners and kickers are glued in, I expect this to be quite solid.

For the last couple of hours since I got back, I've dyeing my fingers brown [no, really!!

] in preparation to glue the end frames up some time tomorrow (hopefully). Again, Mailee's tip of applying a thin coat of sealer first was used here. After staining, I added knotting solution where required. You'll also note I've done the inside edges of the frame components. Trust me, it's much easier to do them now!! :wink:

I'm not sure why but, these just seem to have come out even better this time... 8)

Hopefully then, I'll be able to get those end frames glued up tomorrow. Trouble is, I am literally in-and-out all-day.

We'll see what happens! :wink: