Good Surname or what ?

Established Member

Earlier this year I asked for help on this tuit.Thanks for all the great advice.

I finally got around to working on it. I biscuited the 5 components together - though I'm not sure what I did with the photos :roll:. So they (may) follow.

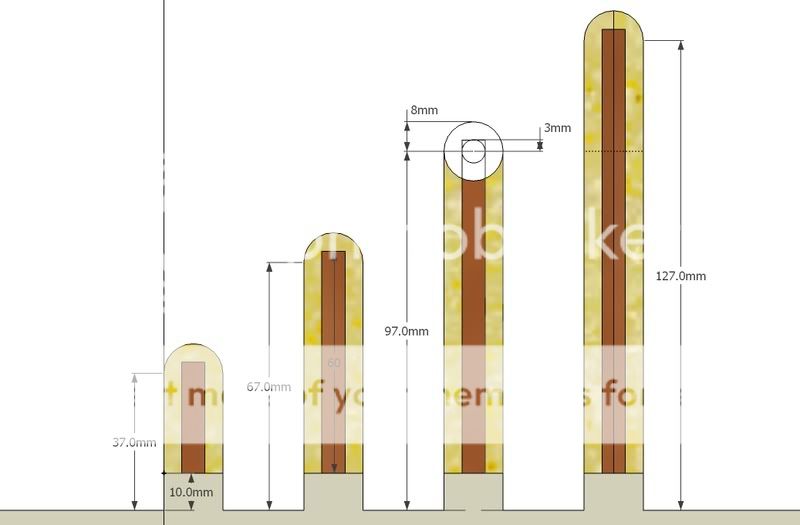

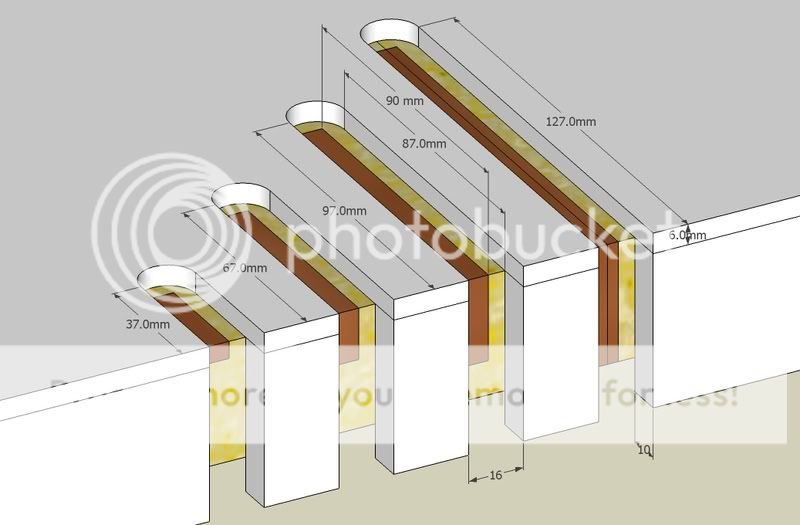

My overall idea is to plagiarise the designs of Philip Hearsey. Philip makes tables/desks that lean against walls. I'd like to terminate my "leg" in a turned cylinder; as below. I've made contact with Chunkolini to see if he can help with fabricating the metalwork.

Today I trimmed the top to length with the router using my trusty "Brian Boggs shave horse" as a bench. Its great because you can clamp things in all sorts of ways - and work outside in the sun.

In the next picture you can clearly see where I need to disguise the end-grain joints.

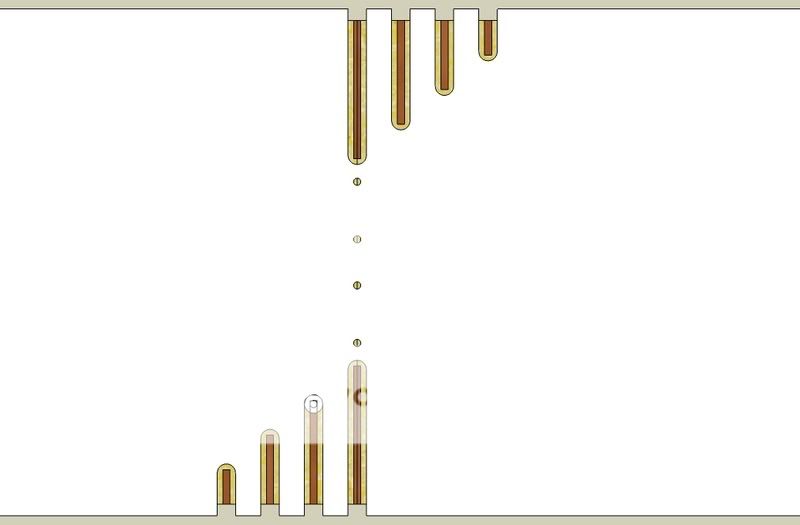

I plan to use a spiral down-cut router bit to ensure clean edges on the cross-grain trenches for the inlay pieces. I intend to make a template and use a guide bush. Hopefully this will ensure accurate symmetry of the inlay.

Note the use of "hopefully" - the router and I are not soulmates.

I'll keep you posted.

I finally got around to working on it. I biscuited the 5 components together - though I'm not sure what I did with the photos :roll:. So they (may) follow.

My overall idea is to plagiarise the designs of Philip Hearsey. Philip makes tables/desks that lean against walls. I'd like to terminate my "leg" in a turned cylinder; as below. I've made contact with Chunkolini to see if he can help with fabricating the metalwork.

Today I trimmed the top to length with the router using my trusty "Brian Boggs shave horse" as a bench. Its great because you can clamp things in all sorts of ways - and work outside in the sun.

In the next picture you can clearly see where I need to disguise the end-grain joints.

I plan to use a spiral down-cut router bit to ensure clean edges on the cross-grain trenches for the inlay pieces. I intend to make a template and use a guide bush. Hopefully this will ensure accurate symmetry of the inlay.

Note the use of "hopefully" - the router and I are not soulmates.

I'll keep you posted.