RogerS

Established Member

I'm in the process of renovating our en-suite. Last done in 1995 and the stone bath bought in a sale has sat in what was our dining room for the last three years (so LOML tells me). However I am in a bit of a quandary.

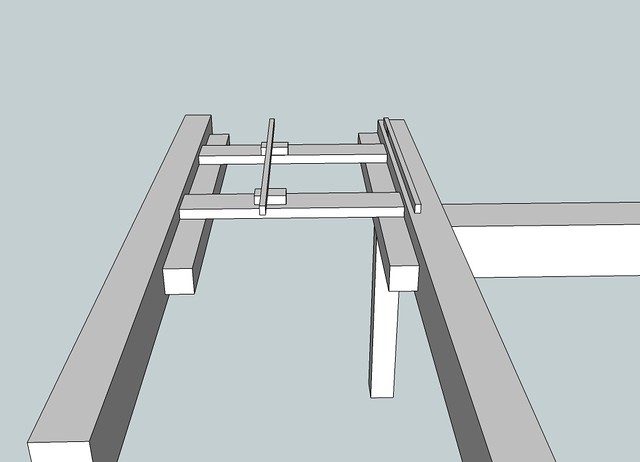

When our builder removed a staircase and made good the ceiling way back in 1990, he was a bit of a bodger and at the time I didn't know any better either. So he simply nailed bits of old oak, that had come out from other parts of the building, as supports to the sides of the beams on either side of where the staircase went. He then laid some odd oak beams between these supports and plasterboarded over the gap. He knew that we were fitting a corner bath (as it was all the rage then) and so did plan ahead and put a supplementary vertical supporting beam to give additional strength to the beam that spanned the width of the kitchen. So far so good. The oak beam supports do look a bit naff now TBH and I'd never let him get away with it were he around today.

These are the supports on the outside wall

and these are on the side of the beam spanning the kitchen and the vertical extra supporting beam in the background

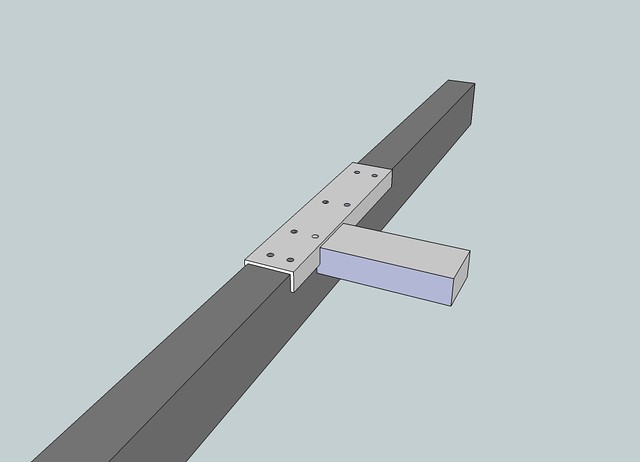

Notice the small arrow pointing at an empty mortice. I'll come back to that.

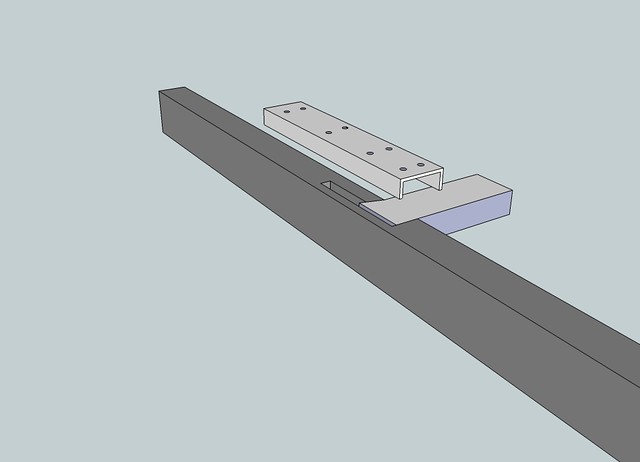

From the top we see this

Remember that empty mortice ?

Well, it's roughly beneath this empty mortice

and you can also see the half-wedge tenon on the end of the cross beam (in the picture above) that ties into the main spanning beam

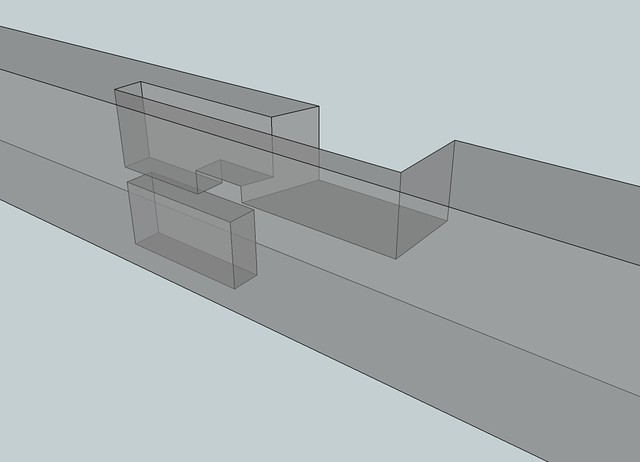

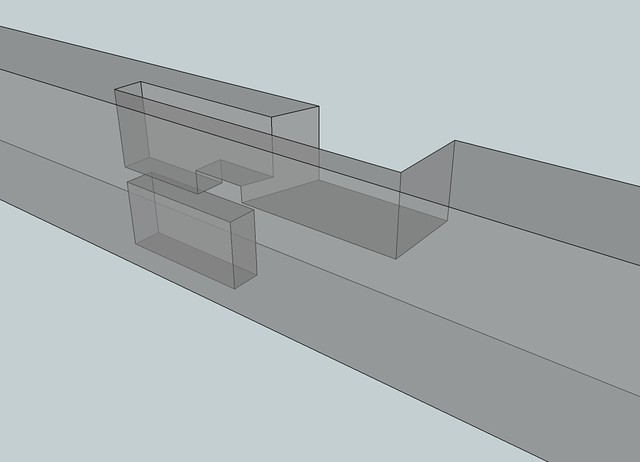

and if I draw this out in SketchUp it looks like this

and in x-ray

and although that beam is pretty chunky at 135mm wide x 210mm deep, there ain't a lot of meat left around that joint. Let's face it, my builder probably put the vertical support in the wrong place but it can't be moved as there are tiles around it. And sticking in another vertical supporting beam is going to look a bit naff.

Now my quandary. The new bath going in weighs 68kg. Filled to the brim, 368kg. It's base is roughly here although more oval than round.

and I am wondering if that spanning beam is going to be strong enough around that joint. There is some extra support from that side support but is that enough? Is it actually needed or is that spanning beam joint good enough?

If it needs strengthening I see a few options.

1) Easiest is to fit a very tight fitting stub of a tenon into that top mortice slot as the sides should resist inward pressure if the bath tried to deflect the beam downwards (I think that is right). And fit one into the bottom mortice but pegged ...as this will be under tension if the bath deflects the beam downwards.

2) Least favourite is to remove the ceiling and replace that inner supporting piece with something a bit meatier running the whole height of the spanning beam...coachbolted into the spanning beam with counterbored holes filled with mock oak pegs. Then fiddle about forever and a day with stain trying to match the new oak with the old. And make good the ceiling.

What does the team think?

TIA

When our builder removed a staircase and made good the ceiling way back in 1990, he was a bit of a bodger and at the time I didn't know any better either. So he simply nailed bits of old oak, that had come out from other parts of the building, as supports to the sides of the beams on either side of where the staircase went. He then laid some odd oak beams between these supports and plasterboarded over the gap. He knew that we were fitting a corner bath (as it was all the rage then) and so did plan ahead and put a supplementary vertical supporting beam to give additional strength to the beam that spanned the width of the kitchen. So far so good. The oak beam supports do look a bit naff now TBH and I'd never let him get away with it were he around today.

These are the supports on the outside wall

and these are on the side of the beam spanning the kitchen and the vertical extra supporting beam in the background

Notice the small arrow pointing at an empty mortice. I'll come back to that.

From the top we see this

Remember that empty mortice ?

Well, it's roughly beneath this empty mortice

and you can also see the half-wedge tenon on the end of the cross beam (in the picture above) that ties into the main spanning beam

and if I draw this out in SketchUp it looks like this

and in x-ray

and although that beam is pretty chunky at 135mm wide x 210mm deep, there ain't a lot of meat left around that joint. Let's face it, my builder probably put the vertical support in the wrong place but it can't be moved as there are tiles around it. And sticking in another vertical supporting beam is going to look a bit naff.

Now my quandary. The new bath going in weighs 68kg. Filled to the brim, 368kg. It's base is roughly here although more oval than round.

and I am wondering if that spanning beam is going to be strong enough around that joint. There is some extra support from that side support but is that enough? Is it actually needed or is that spanning beam joint good enough?

If it needs strengthening I see a few options.

1) Easiest is to fit a very tight fitting stub of a tenon into that top mortice slot as the sides should resist inward pressure if the bath tried to deflect the beam downwards (I think that is right). And fit one into the bottom mortice but pegged ...as this will be under tension if the bath deflects the beam downwards.

2) Least favourite is to remove the ceiling and replace that inner supporting piece with something a bit meatier running the whole height of the spanning beam...coachbolted into the spanning beam with counterbored holes filled with mock oak pegs. Then fiddle about forever and a day with stain trying to match the new oak with the old. And make good the ceiling.

What does the team think?

TIA