Hi all

I'm about to start on a little project (well, probably not quite so little!), and i'm in the process of putting a design together. This won't be a quick WIP, as I intend to do it in between all my other stuff, but i'd like to try and get it finished before Christmas.

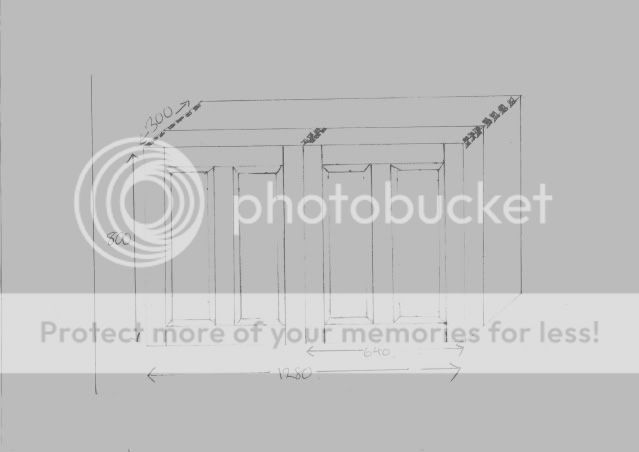

I will be building a cabinet out of Oak, but rather than have normal doors, I intend to create a box door so that tools can be hung inside the door. Similair to that shown in Lord Nibbo's thread here. However, I want the fronts of the doors to have a shaker style - and there's my first conundrum. How do you make such a construction. The only way I can think of is to make the door carcass first and then fix (glue?) the door onto the carcass. I'm not sure how good this would look.

Any help appreciated.

Cheers

Karl

I'm about to start on a little project (well, probably not quite so little!), and i'm in the process of putting a design together. This won't be a quick WIP, as I intend to do it in between all my other stuff, but i'd like to try and get it finished before Christmas.

I will be building a cabinet out of Oak, but rather than have normal doors, I intend to create a box door so that tools can be hung inside the door. Similair to that shown in Lord Nibbo's thread here. However, I want the fronts of the doors to have a shaker style - and there's my first conundrum. How do you make such a construction. The only way I can think of is to make the door carcass first and then fix (glue?) the door onto the carcass. I'm not sure how good this would look.

Any help appreciated.

Cheers

Karl