scrob

Member

Hi guys, just joined the forum, looks great! I have just posted my last creation in the projects section, take a look here: https://www.ukworkshop.co.uk/forums/view ... hp?t=30050

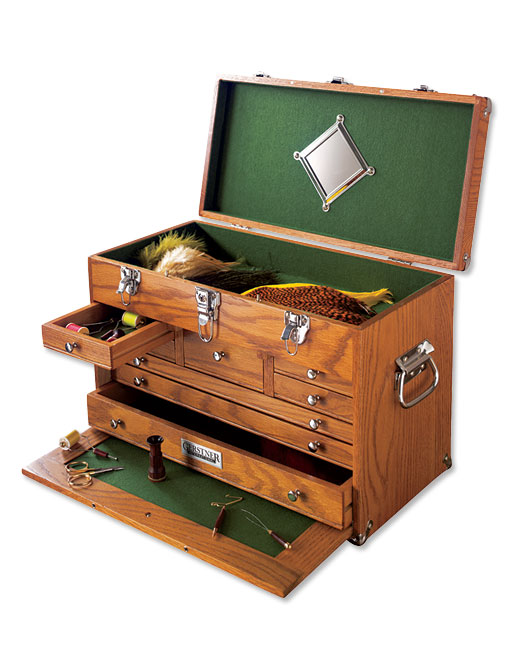

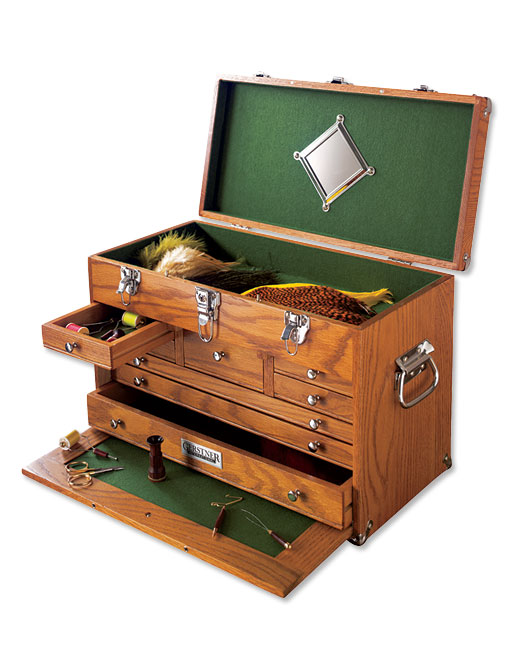

Anyway, I joined up for some specific advice on the next project I am planning. I want to make a hard wood cabinet to house some fly tying equipment. I am currently drawing plans for it, but have some preliminary questions:

- Can I use real solid oak, of around 18mm thick? I have been warned it may warp over time as it dries out.

- If I can use the oak, where do I get boards broad enough to make a cabinet?

- For a complete novice, full of the best will in the world, how hard is it to make dove tail joints? I have searched and seen the array of specialist saws that can be used, and I would be prepared to buy the right tool for the job. But just wondering if it is within the reach of an eager novice.

That will do for now - I look forward to your replies.

Rob

Ps - this cabinet is my main inspiration:

Anyway, I joined up for some specific advice on the next project I am planning. I want to make a hard wood cabinet to house some fly tying equipment. I am currently drawing plans for it, but have some preliminary questions:

- Can I use real solid oak, of around 18mm thick? I have been warned it may warp over time as it dries out.

- If I can use the oak, where do I get boards broad enough to make a cabinet?

- For a complete novice, full of the best will in the world, how hard is it to make dove tail joints? I have searched and seen the array of specialist saws that can be used, and I would be prepared to buy the right tool for the job. But just wondering if it is within the reach of an eager novice.

That will do for now - I look forward to your replies.

Rob

Ps - this cabinet is my main inspiration: