devonwoody

Established Member

Put the Chevron box aside for a while (the lid is giving me agro) so started another box with a new idea:

The corner mitres are going to have contrasting corners fitted (but not stringers). Also will attempt to use contrasts at other sections of box.

Purchased this 5to 6ft. length of American Ash last year at Yandles and I have stored it in my computer room over the past 4 months so it would be ready to work on this spring.

The board has some nice grain effects so I have chopped off a 36" length and cut a 2" thick board out of the centre of board along its length which has the strong grain effect.

The board from this centre piece has produced three nice selections with grain for making three boxes.

I prepared one length which was sawn, planed, thicknessed and then rebated top and bottom edge before cutting to the 4 box sections maintaining the grain pattern at each corner. (accept the last one of course).

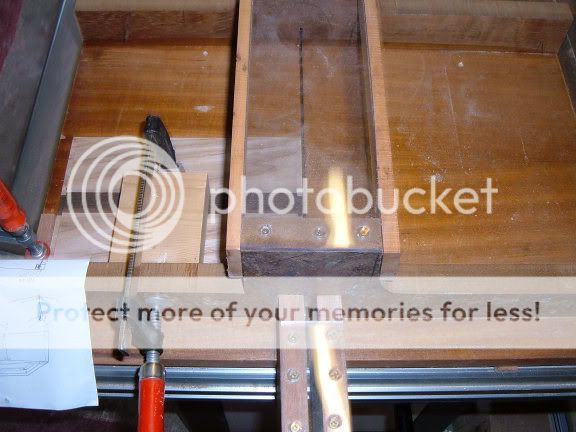

The 4 mitres were cut using the table saw mitre jig and I must confirm the cuts appear perfect. (I use many clamps at the jig to ensure there can be no movement of timber whilst it is being cut, also side lengths are maintained with spacing blocks.

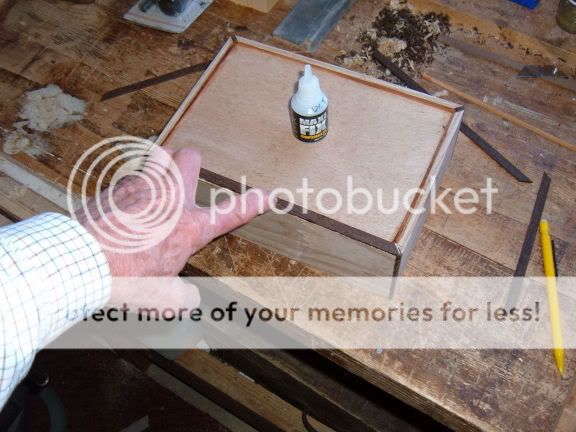

This picture shows my usual layout to confirm that pieces have been cut accurately and should give good corner joints.

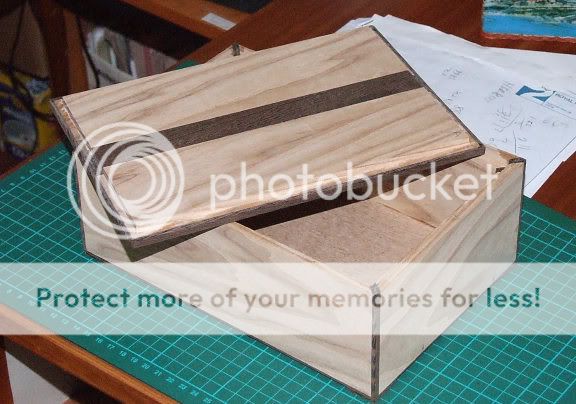

This is where the change of routine is now going to take place, I am going to insert a coloured contrast (wenge 2mm thick) to each mitred cut making 8 slices in total.

This means that the corner joints are not going to be 100% end grain glued joins.

Final picture shows the sections with the piece of prepared wenge ready for the next session.

My next problem is that I have now got a few days of gardening to pursue because spring will not wait any longer, so depending on weather will decide on my return to the workshop.

The corner mitres are going to have contrasting corners fitted (but not stringers). Also will attempt to use contrasts at other sections of box.

Purchased this 5to 6ft. length of American Ash last year at Yandles and I have stored it in my computer room over the past 4 months so it would be ready to work on this spring.

The board has some nice grain effects so I have chopped off a 36" length and cut a 2" thick board out of the centre of board along its length which has the strong grain effect.

The board from this centre piece has produced three nice selections with grain for making three boxes.

I prepared one length which was sawn, planed, thicknessed and then rebated top and bottom edge before cutting to the 4 box sections maintaining the grain pattern at each corner. (accept the last one of course).

The 4 mitres were cut using the table saw mitre jig and I must confirm the cuts appear perfect. (I use many clamps at the jig to ensure there can be no movement of timber whilst it is being cut, also side lengths are maintained with spacing blocks.

This picture shows my usual layout to confirm that pieces have been cut accurately and should give good corner joints.

This is where the change of routine is now going to take place, I am going to insert a coloured contrast (wenge 2mm thick) to each mitred cut making 8 slices in total.

This means that the corner joints are not going to be 100% end grain glued joins.

Final picture shows the sections with the piece of prepared wenge ready for the next session.

My next problem is that I have now got a few days of gardening to pursue because spring will not wait any longer, so depending on weather will decide on my return to the workshop.