Corset

Established Member

After trawling the web and all the advice on this fantastic site i have finally, nearly, ish completed my workbench. After a slight diversion with a bandsaw (many thanks all) i have taken some snap shots. Please be gentle its my first bench. I am 6ft 2 and hate bending so it is quite tall.

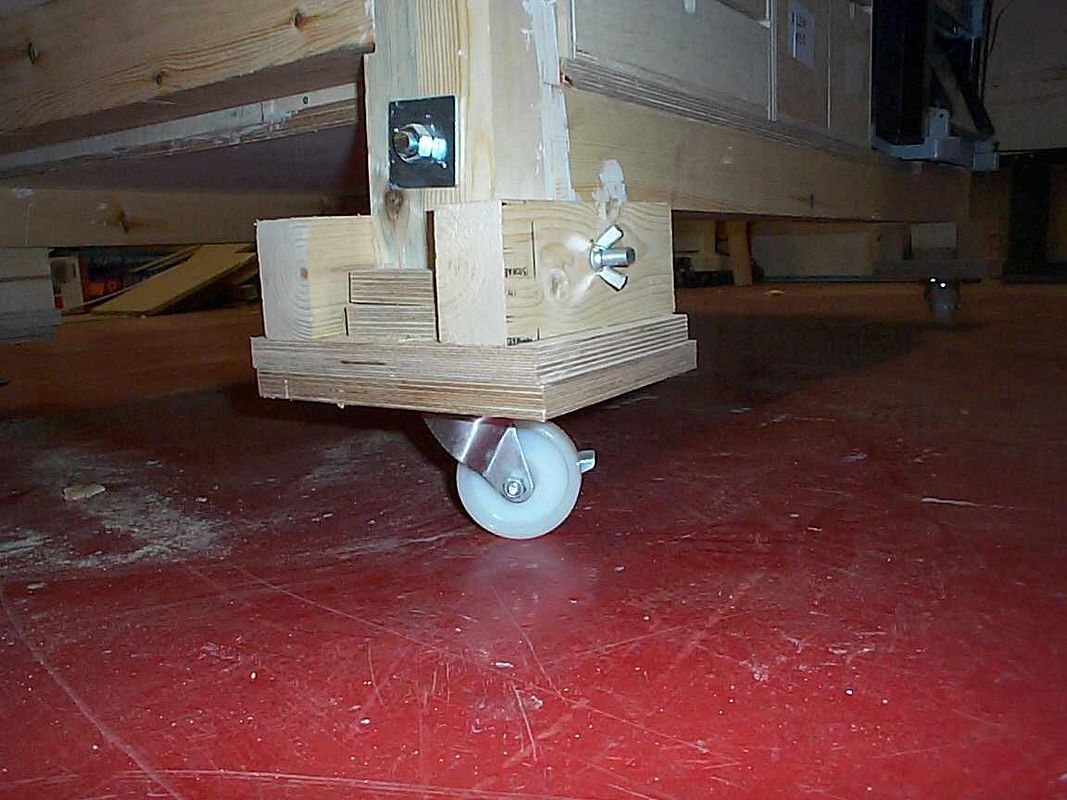

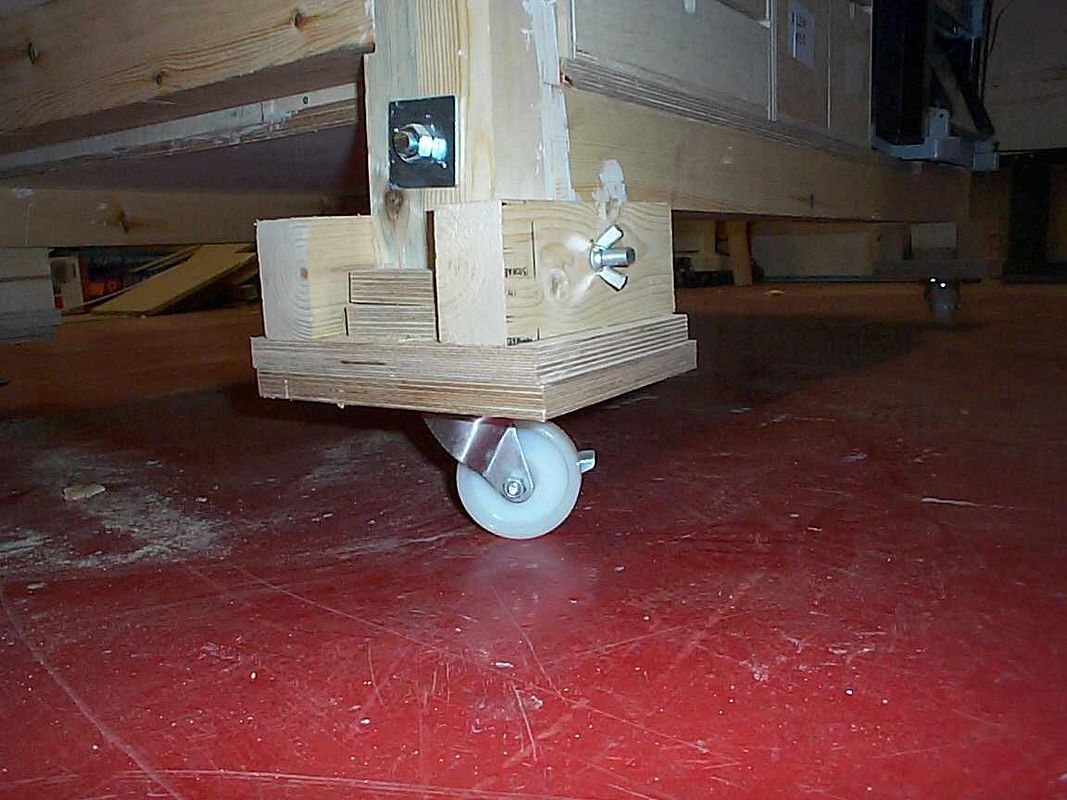

I share my workspace with the works lock up so the bench had to rollable but i needed the wheels to be removable. So i created individual castors for each wheel. Which are attached by a threaded bolt and butterfly nuts. To remove them i jack up the base take them on/off easy and safe.

I then felt it was essential to have drawers which i made badly from from roller slides and plywood. I made them fairly narrow for the top two drawers. One for the planes and one for measuring and marking equip. In plane drawer i also fitted a sub shelf to fit a sliding chisel box which i knocked up. I am happy with the space this gives and is really handy. I stole the idea of a couple of bench i saw on the web. The drawers are lined with antislip stuff which is good at protecting the tools.

I need to store my clamps in the bench as they would be "borrowed" if left them lying around so i devised a slide out drawer section for the clamps. I then banged some shelves on each end.

The bench was made out of some pine 3 by 4 timber i routed out housing joints and bolted and glued together. The top is three sheets of ply and some MDF glued and screwed together. It was very heavy and i am glad for the hours down the gym when i slung it on.

For the top i decided to have a front vise and then drill the top similar to a festool MFT table. THIS WAS A BAD DECISION. Fortunately i didn't drill too many holes :?. Basically i don,t know why but the clamps when under pressure lift the item being clamped. I think this was because the holes were not drilled at 90 (foolishly didn't thinka degree or two made a difference) and the base of the clamps are screwed on the underside of the MFT table.

Realising i had cocked up i decided to drill 19mm hole to fit bench dog and the wonder dogs to try and save the day( hopefully will) I then drilled the table so it is like swiss cheese. (not as in line as they could be as i got a bit drill happy)I then filed the festool clamps to fit 19mm holes and i will extend a dowel to the end to stop them lifting. I have been buying rough sawn timber as i like scrub planing etc so i am going to fit a sort of tail vice. The top was varnished and waxed.

The rear of the bench i have stacked a load of ikea boxes(terrible i know but i didn't want to spend all my time building boxes to put screws in) and my thicknesser (can't do it al by hand).

I have a bit left to do but i am reasonably happy. I am keen to get the endvise sorted to make planing planks a bit easier. Anyway there we go. Glad to contribute a bit after gleaning so much info off the site.

I share my workspace with the works lock up so the bench had to rollable but i needed the wheels to be removable. So i created individual castors for each wheel. Which are attached by a threaded bolt and butterfly nuts. To remove them i jack up the base take them on/off easy and safe.

I then felt it was essential to have drawers which i made badly from from roller slides and plywood. I made them fairly narrow for the top two drawers. One for the planes and one for measuring and marking equip. In plane drawer i also fitted a sub shelf to fit a sliding chisel box which i knocked up. I am happy with the space this gives and is really handy. I stole the idea of a couple of bench i saw on the web. The drawers are lined with antislip stuff which is good at protecting the tools.

I need to store my clamps in the bench as they would be "borrowed" if left them lying around so i devised a slide out drawer section for the clamps. I then banged some shelves on each end.

The bench was made out of some pine 3 by 4 timber i routed out housing joints and bolted and glued together. The top is three sheets of ply and some MDF glued and screwed together. It was very heavy and i am glad for the hours down the gym when i slung it on.

For the top i decided to have a front vise and then drill the top similar to a festool MFT table. THIS WAS A BAD DECISION. Fortunately i didn't drill too many holes :?. Basically i don,t know why but the clamps when under pressure lift the item being clamped. I think this was because the holes were not drilled at 90 (foolishly didn't thinka degree or two made a difference) and the base of the clamps are screwed on the underside of the MFT table.

Realising i had cocked up i decided to drill 19mm hole to fit bench dog and the wonder dogs to try and save the day( hopefully will) I then drilled the table so it is like swiss cheese. (not as in line as they could be as i got a bit drill happy)I then filed the festool clamps to fit 19mm holes and i will extend a dowel to the end to stop them lifting. I have been buying rough sawn timber as i like scrub planing etc so i am going to fit a sort of tail vice. The top was varnished and waxed.

The rear of the bench i have stacked a load of ikea boxes(terrible i know but i didn't want to spend all my time building boxes to put screws in) and my thicknesser (can't do it al by hand).

I have a bit left to do but i am reasonably happy. I am keen to get the endvise sorted to make planing planks a bit easier. Anyway there we go. Glad to contribute a bit after gleaning so much info off the site.