OPJ

Established Member

Hi guys,

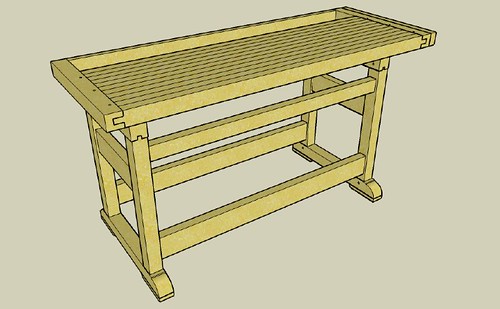

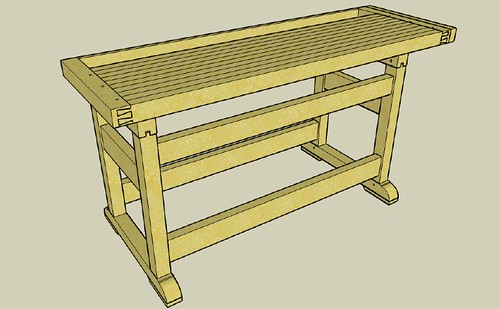

Here's my current design for a new workbench I'm planning to start building fairly soon.

Generally, I'm very happy with what I've come up with and I believe it will do everything I personally want a workbench to do for me (I haven't set out the dog holes yet! :wink .

.

Current dimensions are 1830mm long x 900mm high x 620mm wide. That width measurement is likely to change though.

Couple of areas I need some help with...

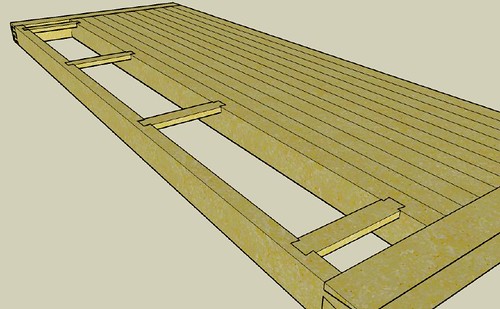

Bench Well

Currently, I've allowed 150mm for the width (top will be 70mm thick). Do you think this is enough, or should I make it wider?

Also, I'd like to make a removable well but I'm not sure how - Jim Tolpin's book doesn't seem to mention it, unless I missed it.

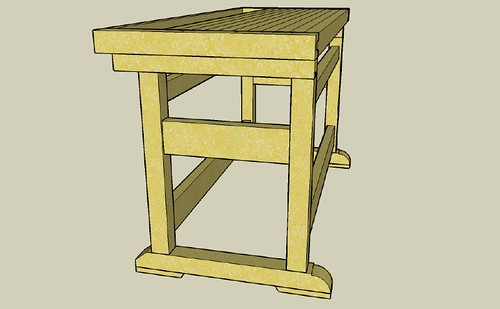

Racking

I know that racking can be a problem when planing boards. I know that normally people would probably fit panels in to either end of the framework. But, I'd like to keep this as 'open' as possible so, I've added an extra rail here - do you think this will make much difference?

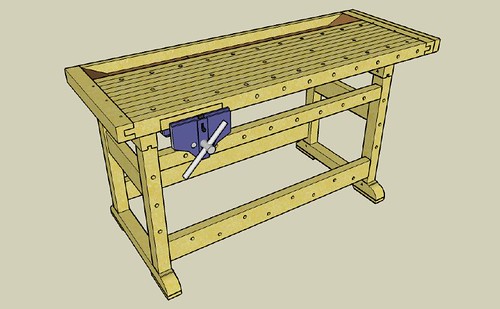

I might also add a series of holes down the length of the right hand length for supporting longer boards (with dowels) - what do you think?

Thanks for looking,

Olly.

Here's my current design for a new workbench I'm planning to start building fairly soon.

Generally, I'm very happy with what I've come up with and I believe it will do everything I personally want a workbench to do for me (I haven't set out the dog holes yet! :wink

Current dimensions are 1830mm long x 900mm high x 620mm wide. That width measurement is likely to change though.

Couple of areas I need some help with...

Bench Well

Currently, I've allowed 150mm for the width (top will be 70mm thick). Do you think this is enough, or should I make it wider?

Also, I'd like to make a removable well but I'm not sure how - Jim Tolpin's book doesn't seem to mention it, unless I missed it.

Racking

I know that racking can be a problem when planing boards. I know that normally people would probably fit panels in to either end of the framework. But, I'd like to keep this as 'open' as possible so, I've added an extra rail here - do you think this will make much difference?

I might also add a series of holes down the length of the right hand length for supporting longer boards (with dowels) - what do you think?

Thanks for looking,

Olly.