sploo

Somewhat extinguished member

This is my version of Marc's Kitchen Helper (http://www.thewoodwhisperer.com/videos/ ... en-helper/). It's a reasonable bit smaller than the original - mostly because our kitchen is tiny.

I was planning on making it from oak, to match our kitchen, but the cost (and the fact I wasn't confident I wouldn't make a mess of it) meant I went for pine.

I've skipped a lot of steps below because Marc's video contains the details, but to make the arcs for the horizontal sections I made a jig, which I've already detailed here: an-arc-or-arch-cutting-template-t91231.html

First I glued up some panels to make the platform. I used a few dominos for alignment:

The long vertical sections were made as Marc suggests - bandsaw for the angle, then clean on the jointer. A dry fit of one side:

I then clamped on a length of spare wood to use as a fence for the Domino so I could cut the mortises on the face of the side panel:

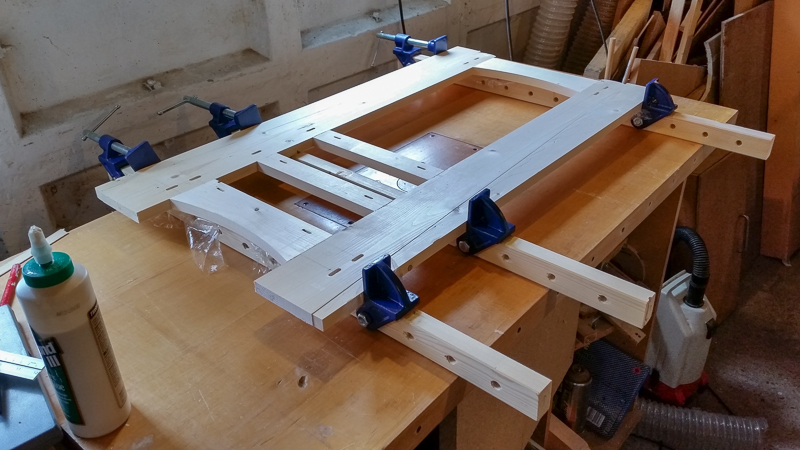

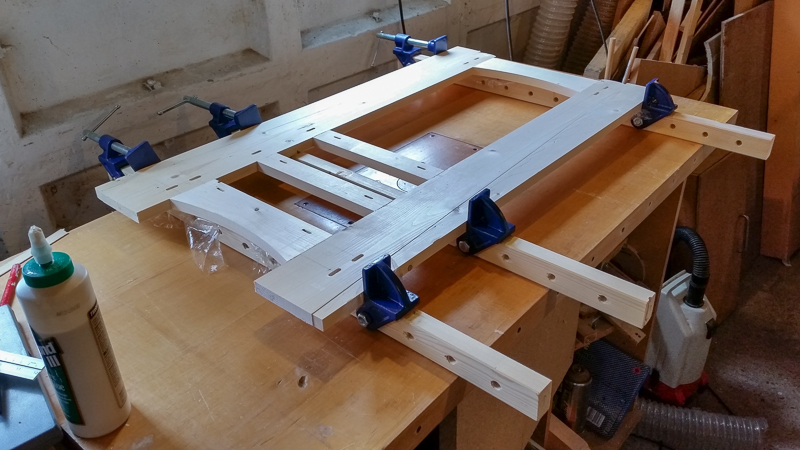

Glueing one side - using the offcuts from the vertical sections to aid clamping:

Testing the fit of the vertical beams that join the two sides:

Rounding over the panel using a router (the separate horizontals were done on the router table, as per Marc's video):

The finished article (coated in a food-safe blend of mineral oil and beeswax):

I was planning on making it from oak, to match our kitchen, but the cost (and the fact I wasn't confident I wouldn't make a mess of it) meant I went for pine.

I've skipped a lot of steps below because Marc's video contains the details, but to make the arcs for the horizontal sections I made a jig, which I've already detailed here: an-arc-or-arch-cutting-template-t91231.html

First I glued up some panels to make the platform. I used a few dominos for alignment:

The long vertical sections were made as Marc suggests - bandsaw for the angle, then clean on the jointer. A dry fit of one side:

I then clamped on a length of spare wood to use as a fence for the Domino so I could cut the mortises on the face of the side panel:

Glueing one side - using the offcuts from the vertical sections to aid clamping:

Testing the fit of the vertical beams that join the two sides:

Rounding over the panel using a router (the separate horizontals were done on the router table, as per Marc's video):

The finished article (coated in a food-safe blend of mineral oil and beeswax):