You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

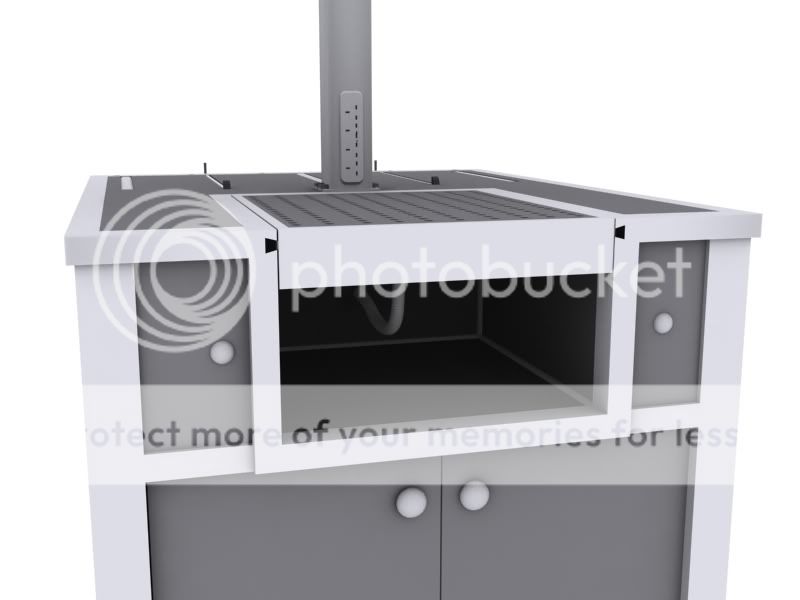

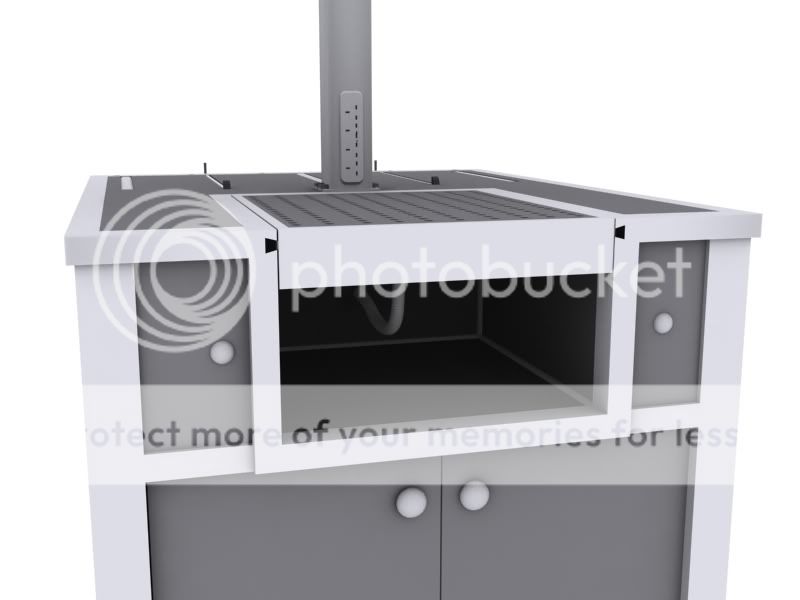

My ultimate Workstation Design

- Thread starter Chems

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hi Chems

A few things I would think about if I were you...

1) The table saw in that position would interfere with running long boards over the router table - although the model is without dimension, I can see that it would cause problems for any board over a few feet in length.

2) I would recommend setting the saw and router further back from the edge to provide better support before the cutters

3) Perhaps you could somehow attached the centre column more to one side reaching over? That way by removing the fences and vices you would have a large support for the table saw, allowing you to more easily handle large man-made boards.

My only other thoughts were how you propose to fit the table saw (do you have one in mind - I would think it might be difficult to build into the table). Also, perhaps it might work better as two separate units? That way you could roll them back along a wall, taking up less space - and arrange one to act as infeed/outfeed tables for the other as required.

Nice models by the way

A few things I would think about if I were you...

1) The table saw in that position would interfere with running long boards over the router table - although the model is without dimension, I can see that it would cause problems for any board over a few feet in length.

2) I would recommend setting the saw and router further back from the edge to provide better support before the cutters

3) Perhaps you could somehow attached the centre column more to one side reaching over? That way by removing the fences and vices you would have a large support for the table saw, allowing you to more easily handle large man-made boards.

My only other thoughts were how you propose to fit the table saw (do you have one in mind - I would think it might be difficult to build into the table). Also, perhaps it might work better as two separate units? That way you could roll them back along a wall, taking up less space - and arrange one to act as infeed/outfeed tables for the other as required.

Nice models by the way

Chems

Established Member

Thanks for the input, I see what you mean about about pushing the 2 back. I forgot to mention that the router tables guides are able to be completely removed by pushing them all the way back to where the square is at the start of the dove tail and lifting it out. Then drop the head of the router in and you have that whole section free for the saw, same goes for the table top vices they can be taken out and dropped down to give free access for ripping.

I like the idea of moving the column over but I dont do a whole lot of cutting on the saw and if I really needed to I could make up a bit of a saw horse to put next to the table and work with the overhang off the side of the table?

Love the 2 tables idea that would save me a lot of space, but its more difficult with hooking it all up to the 1 dust extractor unit.

Ive been out and measured up, I have exactly 4"6 Feet square to play with and the table height on casters has to be 3 feet exactly also including the folded down center column.

The table saw is a Triton 10inch and measures 17L 26W and 13D I have no fancy ideas of mounting it other than it to be sitting on a shelf below with a square cut in the work surface for the top to protrude.

Im going to start working on scaling it up now.

EDIT: Just had a look in scale, your right defiantly need to move the table saw about to get maximum use of space.

I like the idea of moving the column over but I dont do a whole lot of cutting on the saw and if I really needed to I could make up a bit of a saw horse to put next to the table and work with the overhang off the side of the table?

Love the 2 tables idea that would save me a lot of space, but its more difficult with hooking it all up to the 1 dust extractor unit.

Ive been out and measured up, I have exactly 4"6 Feet square to play with and the table height on casters has to be 3 feet exactly also including the folded down center column.

The table saw is a Triton 10inch and measures 17L 26W and 13D I have no fancy ideas of mounting it other than it to be sitting on a shelf below with a square cut in the work surface for the top to protrude.

Im going to start working on scaling it up now.

EDIT: Just had a look in scale, your right defiantly need to move the table saw about to get maximum use of space.

wizer

Established Member

- Joined

- 3 Mar 2005

- Messages

- 15,589

- Reaction score

- 1

Nice idea in principle, but I don't think it's going to work in practice. That central beam is just going to get in the way. Have you seen this?

http://christophermerrill.net/ww/plans/ ... and_1.html

http://sketchup.google.com/3dwarehouse/ ... evstart=12

And this:

https://www.ukworkshop.co.uk/forums/view ... sser+fence

http://christophermerrill.net/ww/plans/ ... and_1.html

http://sketchup.google.com/3dwarehouse/ ... evstart=12

And this:

https://www.ukworkshop.co.uk/forums/view ... sser+fence

Chems

I'm not sure if you understood my point (apologies if you did). With the saw blade in place, you would not be able to run a long board over the router. The opposite (using the saw) would, as you say, be fine as the router cutter can be dropped and the fence removed.

Are you planning on mounting a Triton circular saw upside down in the table or have I misunderstood? If so, would you not consider just buying a Triton Workcentre rather than attempting to build your own? I have one and found it easy to use, accurate, and best of all can be hung on the wall when I need the space.

I'm not sure if you understood my point (apologies if you did). With the saw blade in place, you would not be able to run a long board over the router. The opposite (using the saw) would, as you say, be fine as the router cutter can be dropped and the fence removed.

Are you planning on mounting a Triton circular saw upside down in the table or have I misunderstood? If so, would you not consider just buying a Triton Workcentre rather than attempting to build your own? I have one and found it easy to use, accurate, and best of all can be hung on the wall when I need the space.

Chems

Established Member

Mike, thats a miss type by me, didnt mean Triton mean Titan! I have no tools that are as good as a Triton!

WiZer, Ive actually spent the past few weeks reading all 60 pages of the projects forum so I saw that thread which was where I got the idea from for a all inclusive station, I think Im going to go with the modular pod design as I dont have enough space for it all to be in place.

Time for a redesign with these things in mind, Ive done a bit just now and Ive made the table a little longer but a bit narrower, Im going to have it so that when ripping the central pillar can be completely removed easily leaving the top completely flush for 5 feet from front edge to back edge.

WiZer, Ive actually spent the past few weeks reading all 60 pages of the projects forum so I saw that thread which was where I got the idea from for a all inclusive station, I think Im going to go with the modular pod design as I dont have enough space for it all to be in place.

Time for a redesign with these things in mind, Ive done a bit just now and Ive made the table a little longer but a bit narrower, Im going to have it so that when ripping the central pillar can be completely removed easily leaving the top completely flush for 5 feet from front edge to back edge.

£238.91

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

wizer

Established Member

- Joined

- 3 Mar 2005

- Messages

- 15,589

- Reaction score

- 1

Good idea Chems. All my machines are on wheeled cabinets. When I want to use one, I just wheel it out to the middle of the workshop and put it back when finished. Not ideal for work flow if your going between 2 or three machines. But an acceptable compromise IMHO.

Chems

Established Member

Chems

Established Member

Chems

Established Member

Yeah I know what you mean, I learnt when I was younger, Ive tried to learn a few different packages since and I just haven't had the time or lack of life to dedicate to self teaching myself.

Chems

Established Member

Another one of the modules, helping with my dust free requirement!

Similar threads

- Replies

- 0

- Views

- 291

- Replies

- 7

- Views

- 1K

- Replies

- 5

- Views

- 1K

- Replies

- 5

- Views

- 2K