mpooley

Established Member

Hi all

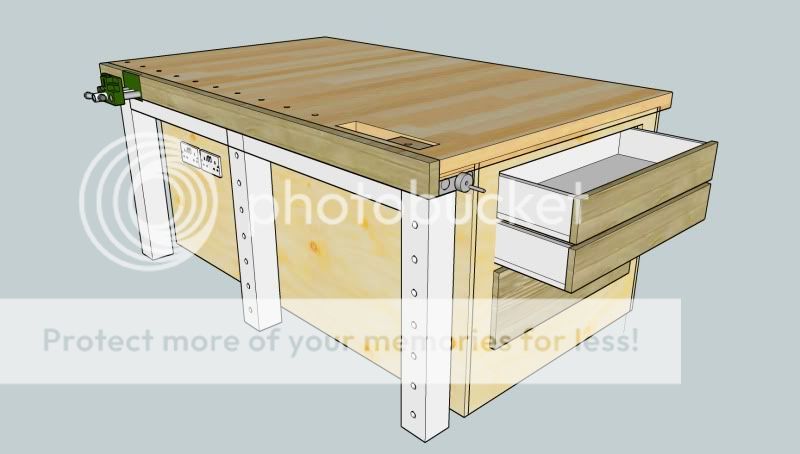

I have decided to refurbish my bench and hope you will enjoy watching me cock it up lol

This is my bench at present - notice that i always keep it clear :?

I have decided these things allready

1. Keep it the same size

2. make it flat - not like the present one

3. add a tail vice

4. add a vacuum inside the bench for my sander - router - biscuit joiner etc

5.add at least one good quality full extension drawer for screws

6.maybe add more tool storage drawers

7.I would like a tool tray thingy to enable me to keep the top clear but i dont want one in the bench - maybe a pullout tray at one end?????

8. keep the 4 electric sockets already built in plus use the auto one fitted to vacuum.

I'm almost decided to use 4mtr beech kitchen worktop cut in two and joined to make a 2mtr x 1200mm top same size as my present one.

am thinking of an oak edge to the top 150mm at front with dog holes in it - maybe same all round not sure ?

I have aquired this device being chucked out at a local machine shop

Im thinking to make this into a wagon vice on the right hand corner

its got 450mm of travel I can shorten it. do you think i should ? I can't see much reason to have it travel much more than 200mm ?

any and all suggestions welcome 8)

Mike

I have decided to refurbish my bench and hope you will enjoy watching me cock it up lol

This is my bench at present - notice that i always keep it clear :?

I have decided these things allready

1. Keep it the same size

2. make it flat - not like the present one

3. add a tail vice

4. add a vacuum inside the bench for my sander - router - biscuit joiner etc

5.add at least one good quality full extension drawer for screws

6.maybe add more tool storage drawers

7.I would like a tool tray thingy to enable me to keep the top clear but i dont want one in the bench - maybe a pullout tray at one end?????

8. keep the 4 electric sockets already built in plus use the auto one fitted to vacuum.

I'm almost decided to use 4mtr beech kitchen worktop cut in two and joined to make a 2mtr x 1200mm top same size as my present one.

am thinking of an oak edge to the top 150mm at front with dog holes in it - maybe same all round not sure ?

I have aquired this device being chucked out at a local machine shop

Im thinking to make this into a wagon vice on the right hand corner

its got 450mm of travel I can shorten it. do you think i should ? I can't see much reason to have it travel much more than 200mm ?

any and all suggestions welcome 8)

Mike