Rumblefuzz

New member

Hello all, this is my first post on the forum after lurking for a while and reading through lots of previous threads, mostly about similar machines. It's impressive to see the amount of combined knowledge floating around in this place... Also, as a non-native english speaker it's been quite a crash course in words like 'trunnion', 'arbour', 'gib' etc...

So, I've been wanting to get into woodworking as a hobby and finally pulled the trigger on a tablesaw. What I got is an early- to mid-sixties Wadkin Bursgreen AGS 10. For my budget which was about 3- to 500 euros, I still think I couldn't have done much better.

Overall the machine is in quite nice shape, but of course there are some things that can or need to be fixed/upgraded. The man I bought the machine from was a retiring woodworker who kindly gave me a lot of tips&tricks on how to use it safely, and also about what I needed to do to this machine to get it up to modern standards.

The main drawbacks with this machine are:

- it didn't come with a riving knife or a blade guard.

- The rise and fall mechanism works well up to about halfway, and then it requires serious force to get it up any further

Then there are a couple things that I'd like to upgrade at some point:

- the rip fence was replaced/repaired and is now a piece of u-shaped steel profile, attached to the old sliding mechanism. It works, but I'm unsure if it's stable enough. It doesn't clamp at the back although there is a rail there and with a bit of force i can bend the end of the rip fence about 4 - 5 mm away from the blade.

- The on/off switch is a starter unit from GE, model nr. SFKOI. The starter unit is in good shape, but the actual on/off switches are a bit small so I have to fumble for the switch when I want to shut off the saw. I'd like to get one of those big paddle switches that i could hit with my knee.

From top to bottom:

- The previous owner gave me a second -old- sawblade, out of which he had meant to cut a new riving knife. I also managed to find scans of the original knife in an old thread on this forum so I could go ahead and find a metal shop that can cut the blade for me. I'm not confident enough in my own metal working skills to do it myself. But I've also looked into aftermarket riving knifes, the regular sort-of banana-shaped ones with a slot. I think that could just be bolted onto the bracket inside my machine. What do you guys suggest is the best option here? Also, besides the thickness, how important is the actual shape of the riving knife?

- I haven't really looked into the rise&fall mechanism yet. I did put a bit of oil in the tracks that it slides in, to not much avail. I don't really know where to start looking to fix this, except that the tilting mechanism works perfectly smooth, so I'm planning to study that one a bit closer to see if there's anything to be learned from that one.

- Does anybody know if there's aftermarket fences that can be installed on a machine sof this type? I have the impression that everything seems to be made for american-made saws like Deltas and Jets, and I wonder if everything would line up the right way.

- The switch is not just an on off switch. It's this GE unit that's apparently called a 'starter'. Even though I dabbled in electronics a little bit, this was completely new to me and besides it being a relay I'm not exactly sure why this is needed. I will assume that it IS needed though, but could anyone point me to a means of installing a new switch that I can install on the machine without any other modifications?

Okay, that's all... Sorry if my post turned out a bit long, I'm just really trying to pick everyone's brains for as much knowledge as I can . Thanks a lot in advance for any tips, tricks, pointers, helpful links etc.

. Thanks a lot in advance for any tips, tricks, pointers, helpful links etc.

So, I've been wanting to get into woodworking as a hobby and finally pulled the trigger on a tablesaw. What I got is an early- to mid-sixties Wadkin Bursgreen AGS 10. For my budget which was about 3- to 500 euros, I still think I couldn't have done much better.

Overall the machine is in quite nice shape, but of course there are some things that can or need to be fixed/upgraded. The man I bought the machine from was a retiring woodworker who kindly gave me a lot of tips&tricks on how to use it safely, and also about what I needed to do to this machine to get it up to modern standards.

The main drawbacks with this machine are:

- it didn't come with a riving knife or a blade guard.

- The rise and fall mechanism works well up to about halfway, and then it requires serious force to get it up any further

Then there are a couple things that I'd like to upgrade at some point:

- the rip fence was replaced/repaired and is now a piece of u-shaped steel profile, attached to the old sliding mechanism. It works, but I'm unsure if it's stable enough. It doesn't clamp at the back although there is a rail there and with a bit of force i can bend the end of the rip fence about 4 - 5 mm away from the blade.

- The on/off switch is a starter unit from GE, model nr. SFKOI. The starter unit is in good shape, but the actual on/off switches are a bit small so I have to fumble for the switch when I want to shut off the saw. I'd like to get one of those big paddle switches that i could hit with my knee.

From top to bottom:

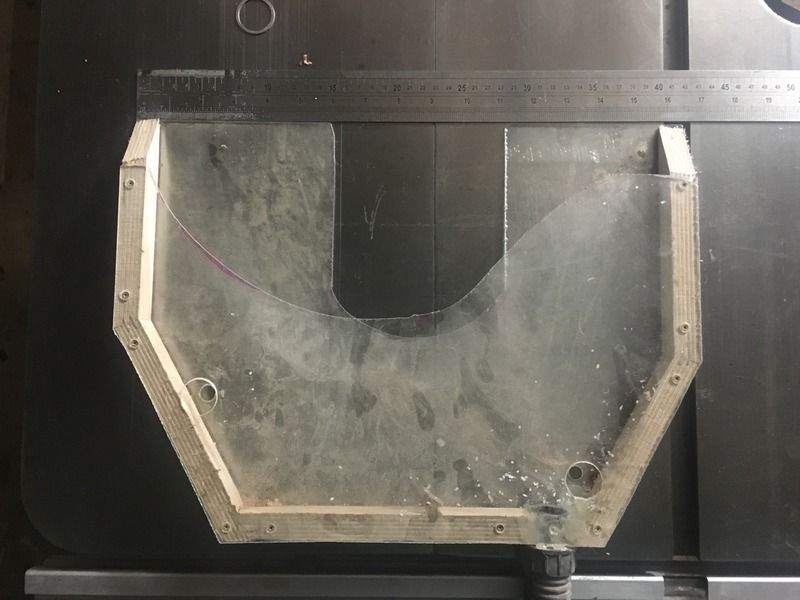

- The previous owner gave me a second -old- sawblade, out of which he had meant to cut a new riving knife. I also managed to find scans of the original knife in an old thread on this forum so I could go ahead and find a metal shop that can cut the blade for me. I'm not confident enough in my own metal working skills to do it myself. But I've also looked into aftermarket riving knifes, the regular sort-of banana-shaped ones with a slot. I think that could just be bolted onto the bracket inside my machine. What do you guys suggest is the best option here? Also, besides the thickness, how important is the actual shape of the riving knife?

- I haven't really looked into the rise&fall mechanism yet. I did put a bit of oil in the tracks that it slides in, to not much avail. I don't really know where to start looking to fix this, except that the tilting mechanism works perfectly smooth, so I'm planning to study that one a bit closer to see if there's anything to be learned from that one.

- Does anybody know if there's aftermarket fences that can be installed on a machine sof this type? I have the impression that everything seems to be made for american-made saws like Deltas and Jets, and I wonder if everything would line up the right way.

- The switch is not just an on off switch. It's this GE unit that's apparently called a 'starter'. Even though I dabbled in electronics a little bit, this was completely new to me and besides it being a relay I'm not exactly sure why this is needed. I will assume that it IS needed though, but could anyone point me to a means of installing a new switch that I can install on the machine without any other modifications?

Okay, that's all... Sorry if my post turned out a bit long, I'm just really trying to pick everyone's brains for as much knowledge as I can