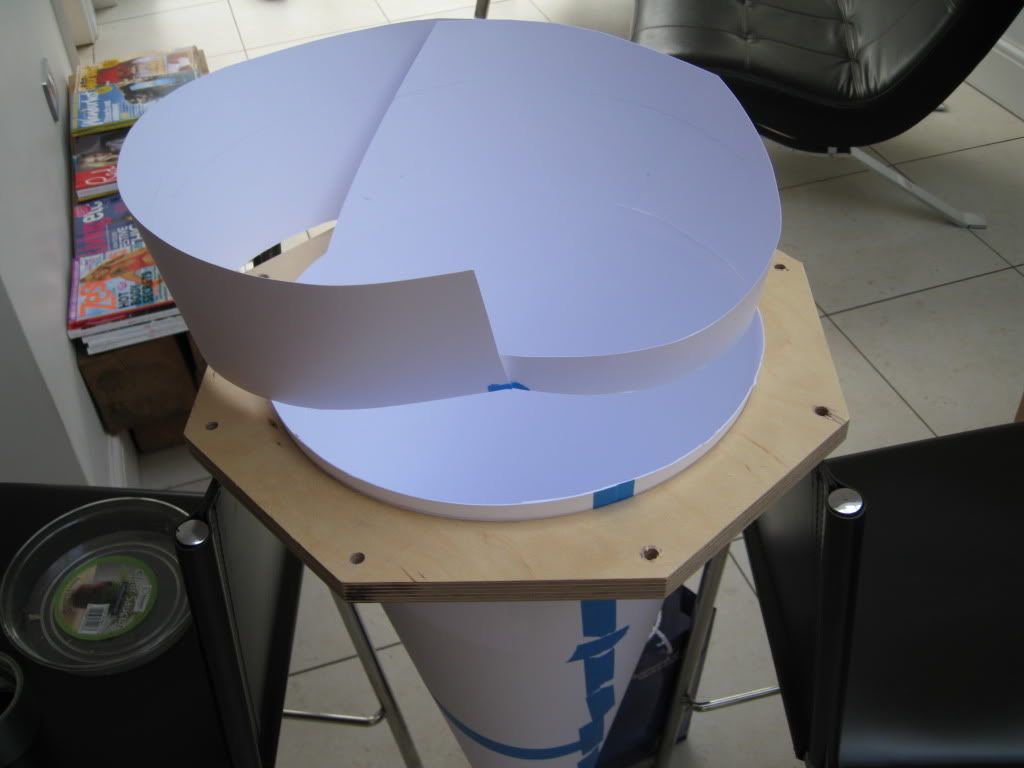

Cyclones seem to be flavour of the month at the moment so I thought I'd post my build.

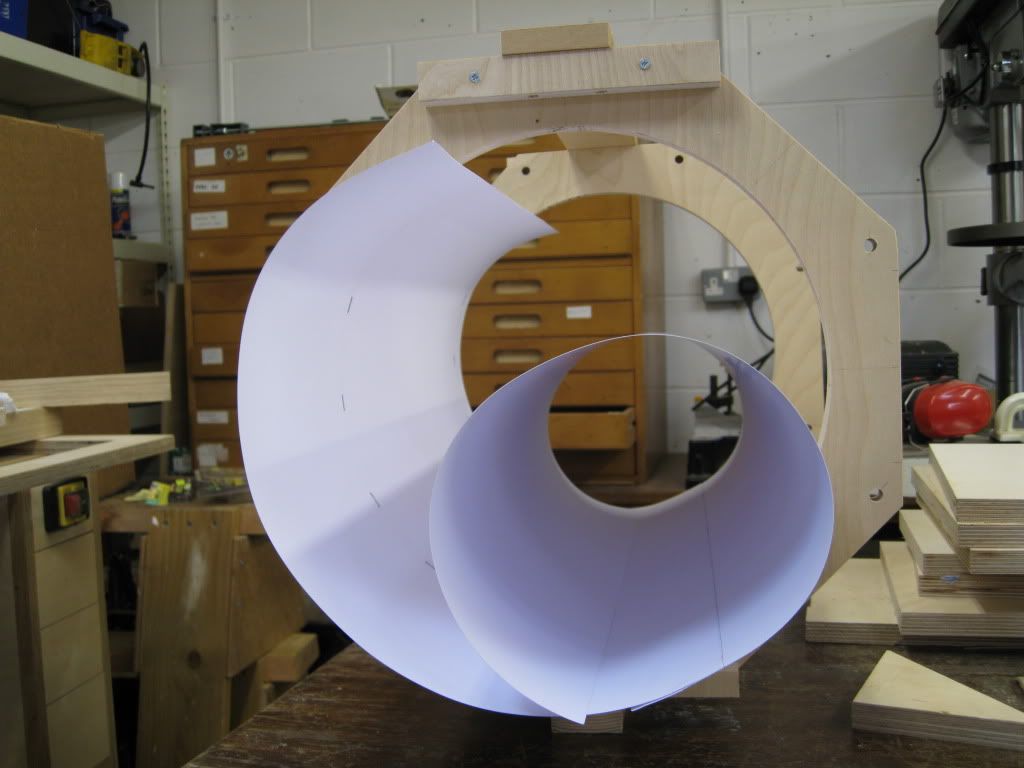

Hopefully it will be a bit of a different build compared to others. Two of the main "ingredients" are going to be cardboard and masking tape - I kid you not, but I'm confident it will work, we'll have to wait and see...

I am basing it on the Bill Pentz design. However I am not intending to get bent out of shape about his complicated maths/airflows etc. It seems to me many people have built all sorts of cyclones without his scientific knowledge and they work very well. My intended ducting size is 4 inch so an immediate departure from Bill's advice. His design calls for 6 inch diameter ducting and an 18 inch diameter cyclone. As my intended ducting size is 2/3 of his I am building a cyclone to 2/3 size of his plans. Thats my rational anyway, it may not work, but I hope it does. Well my cyclone is going to have a 12.5 inch diameter so 2/3ish is probably more accurate.

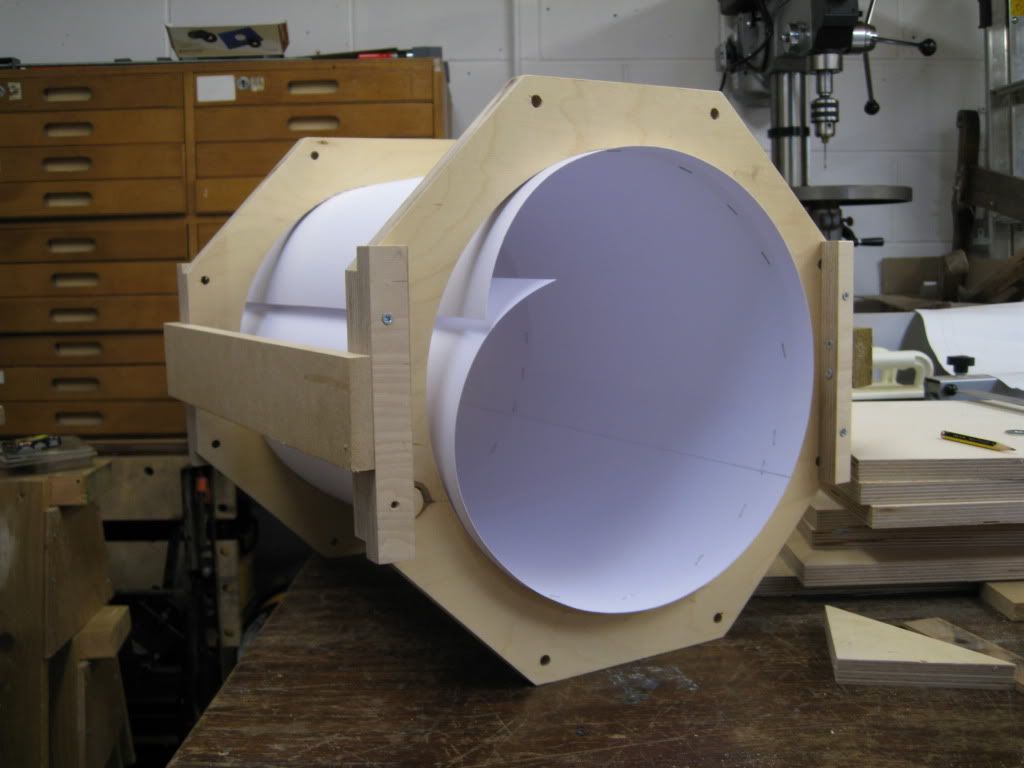

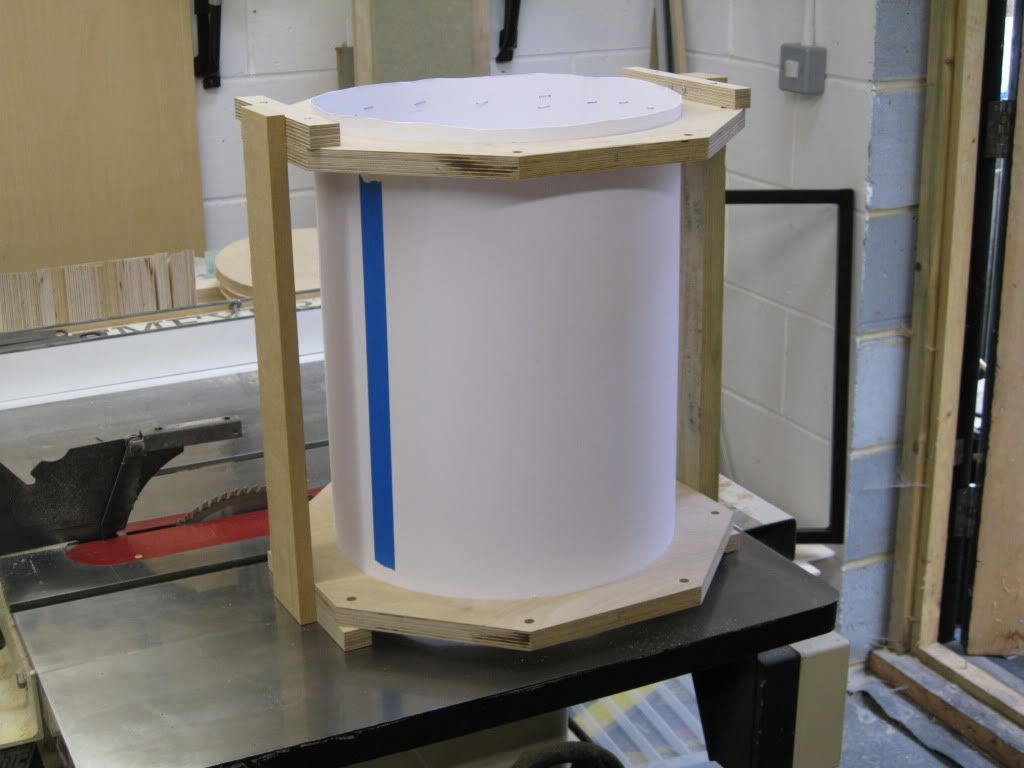

So I started with some birch ply out of a skip and cut 4 squares that are going to be the supports

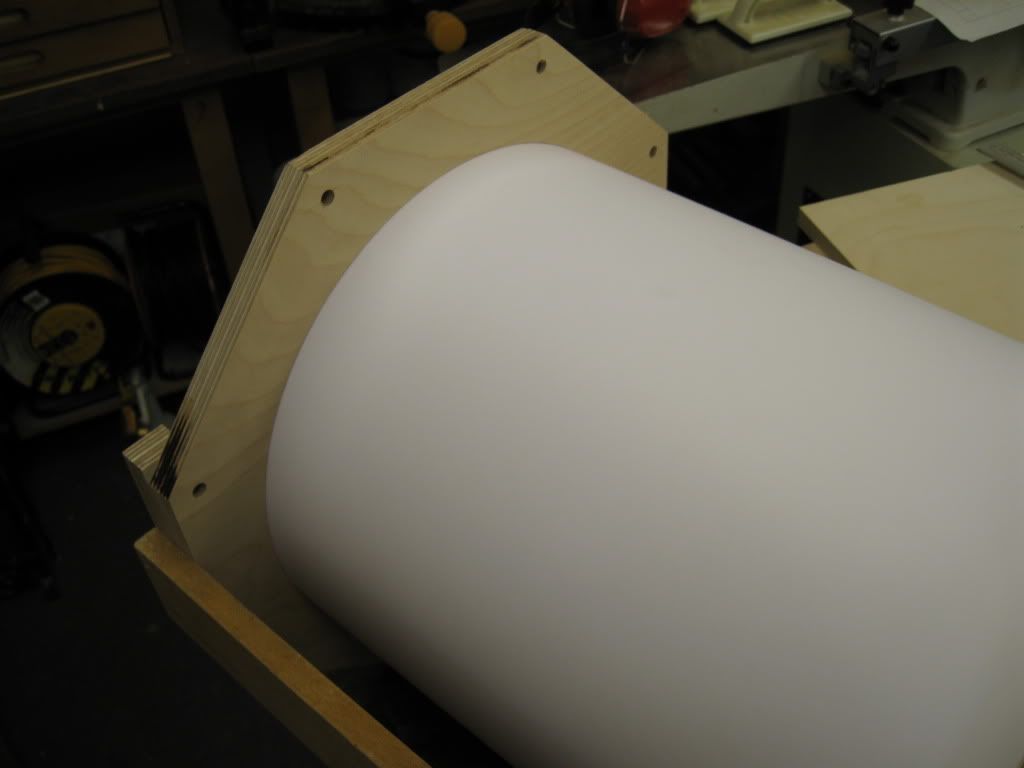

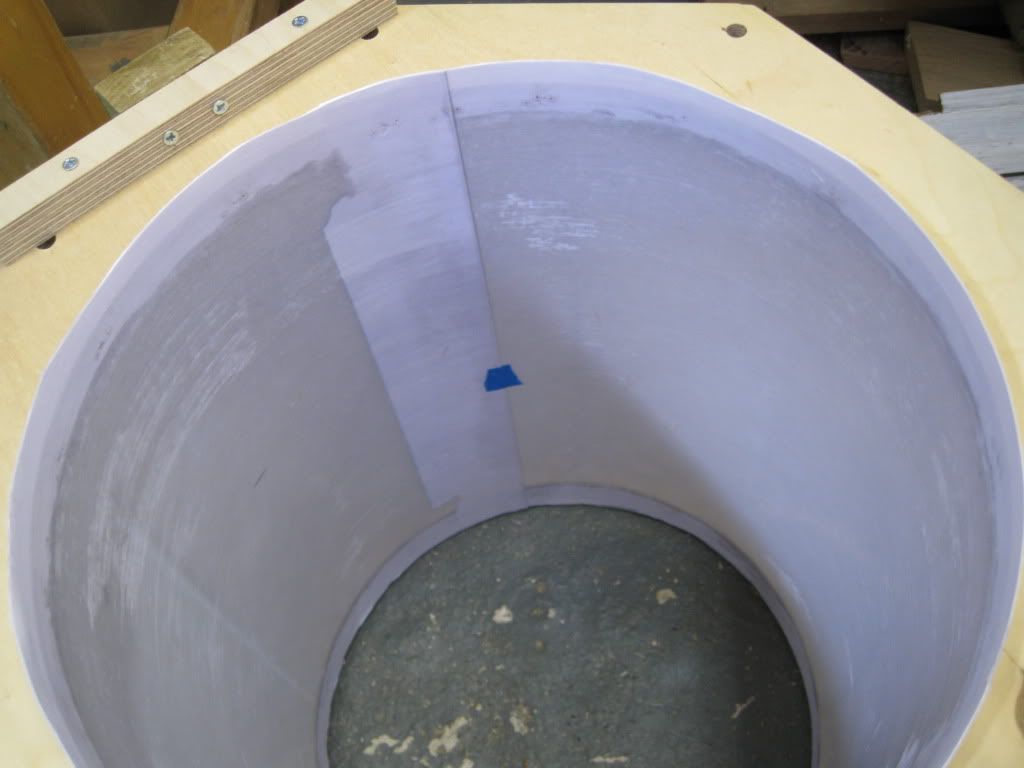

These then had a 12.5 inch diameter hole routed in them. This is the first time I've used the trammel and it was quite easy to use. Didn't quite go all the way through as its the outside I want and didn't want to ruin it.

Hopefully it will be a bit of a different build compared to others. Two of the main "ingredients" are going to be cardboard and masking tape - I kid you not, but I'm confident it will work, we'll have to wait and see...

I am basing it on the Bill Pentz design. However I am not intending to get bent out of shape about his complicated maths/airflows etc. It seems to me many people have built all sorts of cyclones without his scientific knowledge and they work very well. My intended ducting size is 4 inch so an immediate departure from Bill's advice. His design calls for 6 inch diameter ducting and an 18 inch diameter cyclone. As my intended ducting size is 2/3 of his I am building a cyclone to 2/3 size of his plans. Thats my rational anyway, it may not work, but I hope it does. Well my cyclone is going to have a 12.5 inch diameter so 2/3ish is probably more accurate.

So I started with some birch ply out of a skip and cut 4 squares that are going to be the supports

These then had a 12.5 inch diameter hole routed in them. This is the first time I've used the trammel and it was quite easy to use. Didn't quite go all the way through as its the outside I want and didn't want to ruin it.