woodbloke

Established Member

Further to the recent interesting thread on marking gauge mods, the latest copy of F&C dropped onto the mat this morning inside which were the latest current thoughts of Mr C on marking gauges, amongst other interesting stuff yet to be devoured. Another couple of hours work and the already improved gauges are now marvellous....so who needs a Titemark now?...not I :lol:

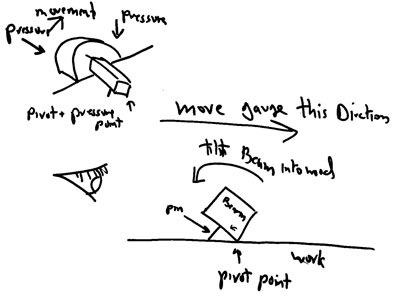

Firstly the stem is handplaned at a steepish angle as in the pic below so that when the brass knob hits the slope of the stem it is forced into the corners of the stock and thus no wobble. Also the aperture from whence the pin protudes has also been relieved to make the minimum projection of the cutter and you can also see the end of it more easily :

Then a slither of a very thick leather belt is shaped and stuck inside the stock under the brass knob to take up any slack as so:

Then comes the pin. I originally modified the existing pin which to say the least is very fiddly. However Mr C recommends a much chunkier pin made from a modified masonry nail, suitable shaped and polished on the Tormek into a small cutting gauge, which is relatively straight forward to do:

The pic above shows the original pin, the front and back of a new pin and the raw material (a large Oboe masonry nail)

The final pic shows the now completed gauges which are now superb, so if you have any of the traditional style gauges, a 40p pack of 7 nails and a couple of hours in the 'shop will transform them....you can flog the wheelgauges of various denominations on the bay...where no doubt Martin will.......

Big thanks to Mr C for an excellent article ccasion5: - Rob

ccasion5: - Rob

Firstly the stem is handplaned at a steepish angle as in the pic below so that when the brass knob hits the slope of the stem it is forced into the corners of the stock and thus no wobble. Also the aperture from whence the pin protudes has also been relieved to make the minimum projection of the cutter and you can also see the end of it more easily :

Then a slither of a very thick leather belt is shaped and stuck inside the stock under the brass knob to take up any slack as so:

Then comes the pin. I originally modified the existing pin which to say the least is very fiddly. However Mr C recommends a much chunkier pin made from a modified masonry nail, suitable shaped and polished on the Tormek into a small cutting gauge, which is relatively straight forward to do:

The pic above shows the original pin, the front and back of a new pin and the raw material (a large Oboe masonry nail)

The final pic shows the now completed gauges which are now superb, so if you have any of the traditional style gauges, a 40p pack of 7 nails and a couple of hours in the 'shop will transform them....you can flog the wheelgauges of various denominations on the bay...where no doubt Martin will.......

Big thanks to Mr C for an excellent article