Just to add an example to this long and interesting thread... I recently made a fairly quick and rough box out of some reclaimed parana pine I had been given. It was a good excuse to do some dovetailing:

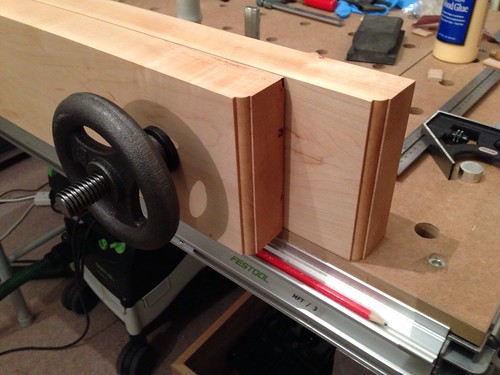

so I was able to use my Moxon vice to pare in between the pins:

not a very well-posed shot but it should show that the broad level surfaces make a jig for the blade. This shows it a bit better:

Parana, like other softwoods, is both tough and soft, so you need very sharp tools and a light cut. In this shot you can see some rough areas - that's just me; but even so they were a lot tidier than in my earlier attempt, where I had tried chopping down onto the bench in the conventional way.

What matters just as much is that the working position is much more comfortable - at my age I have to be careful not to bend over in one position for too long.

Another nice aspect of this particular job was that I found a nice quick way to saw off the waste between the pins and tails - using my foot-powered fret saw:

I could go really quite close to the line and complete a cut quickly. To angle the saw for the end of the cut I just slipped a bit of scrap under the board to tilt it a bit - not something I'd do casually with a motorised saw, but with this you can feel exactly how it is going.