Rhyolith

Established Member

This was basically my thinking. Could do with some suggestion of where to look and who to ask for this kind of job. I am in no rush, it won’t likely happen for at least a year, I am just trying to plan ahead a bit.TFrench":2hsqte4h said:I move a lot of big machines - its easy as I have all the kit through work. For a one off move I'd be looking at paying someone to do it, by the time you've hired a van and trailer you might as well get someone who's set up to do it, and insured!

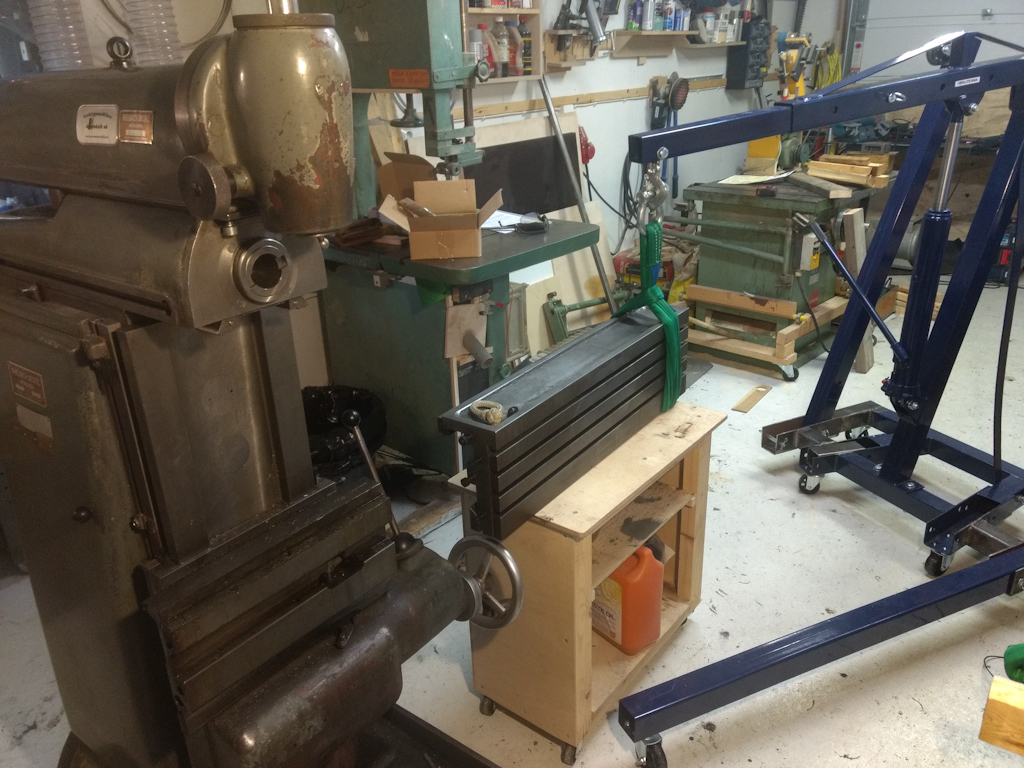

I used rollers, ply and crow bars to get the thing in. However I had the seller of the miller to help (he knew what he was doing) and the rollers were his. I found getting the locak farmer round with the telehandler so concide with the seller arriving a huge pain, so again would rather have one group who can do it on there own.

I knew this thing would be a pain, so worth it though XD