I have often noted people posting that they would like to buy a heavy secondhand cast-iron machine but don't have enough people to move it into their workshop. I love old machines and have so far installed two Boley lathes (100 Kg and 200 Kg) and an Arboga miller (300 kg) in the garage at the front of the house and a Wadkin saw (250 Kg) in the workshop at the end of the garden, so I thought I'd share some experience. I am no weightlifting superman but a moderately fit 75 yr old retired academic engineer, and usually can't call on any strong relatives, friends or neighbours.

The first thing to remember is that one almost never has to lift the full weight of the tool. If part of it is still resting on the ground, or on the edge of the car/van floor, the weight one has to lift is roughly halved - hence 'walking' a machine is much easier than lifting it.

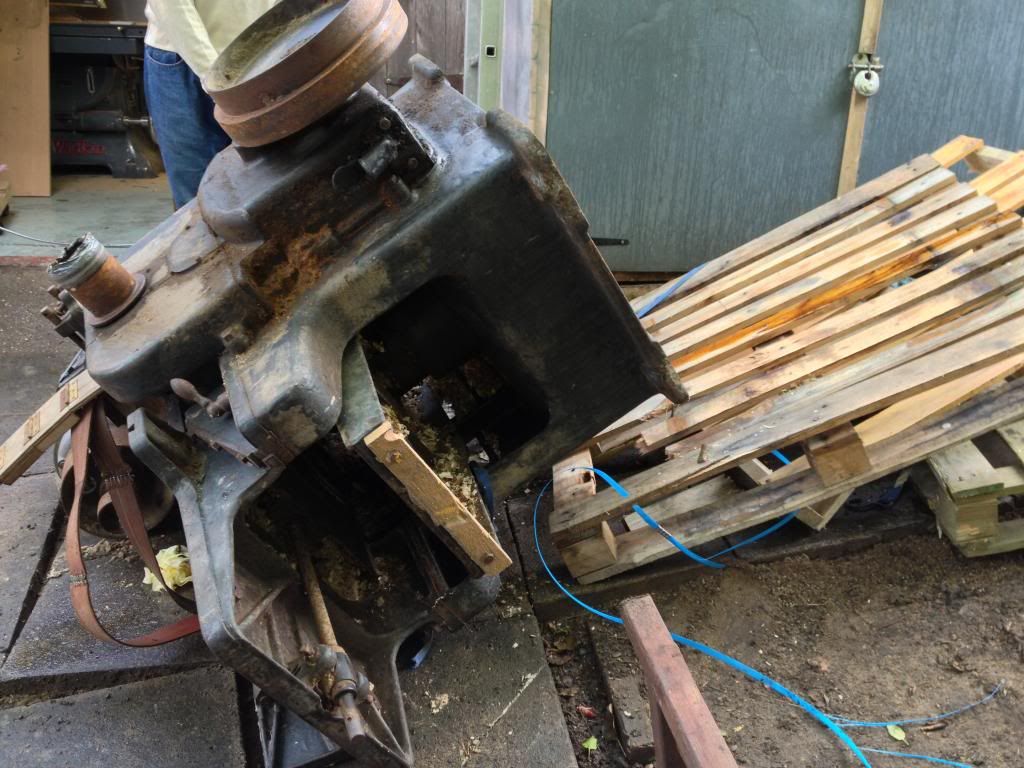

Next is that machines disassemble! The 200 kg lathe took apart into pieces that I could just about lift alone, and very easily with a hoist. Taking the top off the Wadkin saw made it much easier to move, and it could be disassembled much further.

A simple trolley made from 25 mm ply and heavy castors (shown in the pictures) is invaluable. With this the seller and I moved a 200 kg lathe, in pieces, from his garden to my car out front, through his living room, with his wife watching and on guard!

Also shown is a small hydraulic lift. I looked at engine hoists at first, but these are quite expensive, very bulky and difficult to store. The white one in the background of the first picture is an Oxford invalid hoist. These are compact and manoeuvrable as they are intended to navigate round furniture. This one cost £80 on eBay, and came with a 300 lb test certificate and has been invaluable. I rarely use it to lift a tool straight up but have done on occasion, and for reassembling and aligning heavy machines it makes a world of difference.

To do this safely I suggest a few guidelines (still at your own risk!)

1. Never put body parts under or in the falling trajectory of anything heavy!

2. Wear steel-tipped safety shoes.

3. Use proper nylon slings. 1m or 2m slings rated for 1 or 2 tons are cheap on eBay, and rope is often surprisingly weak.

4. Don't be in a hurry, but think through the next move. In particular, think where the machine will end up if it slips or tilts from your ideal arrangement.

5. Use ramps to negotiate steps. If necessary, build a ramp before starting to move the machine.

6. If something is clearly still beyond the efforts of you and your pals, get the machine shipped by pallet delivery (surprisingly cheap) hire a small removal firm (man with a van) for a couple of hours to move it from your drive into your workshop. These guys are immensely strong, have the equipment and know how to move stuff. Call and explain what you want to do.

Of course I am just looking at heavy 'hobby' equipment rather than industrial machines. But there are specialist movers who will handle even these, if you really want that 2 ton super capacity machine. I hope this will stop some people being put off by the thought of installing a machine that is too heavy for them to lift.

An estate car with a lipless boot is strongly recommended!

Anyone else have moving tips to share?

The first thing to remember is that one almost never has to lift the full weight of the tool. If part of it is still resting on the ground, or on the edge of the car/van floor, the weight one has to lift is roughly halved - hence 'walking' a machine is much easier than lifting it.

Next is that machines disassemble! The 200 kg lathe took apart into pieces that I could just about lift alone, and very easily with a hoist. Taking the top off the Wadkin saw made it much easier to move, and it could be disassembled much further.

A simple trolley made from 25 mm ply and heavy castors (shown in the pictures) is invaluable. With this the seller and I moved a 200 kg lathe, in pieces, from his garden to my car out front, through his living room, with his wife watching and on guard!

Also shown is a small hydraulic lift. I looked at engine hoists at first, but these are quite expensive, very bulky and difficult to store. The white one in the background of the first picture is an Oxford invalid hoist. These are compact and manoeuvrable as they are intended to navigate round furniture. This one cost £80 on eBay, and came with a 300 lb test certificate and has been invaluable. I rarely use it to lift a tool straight up but have done on occasion, and for reassembling and aligning heavy machines it makes a world of difference.

To do this safely I suggest a few guidelines (still at your own risk!)

1. Never put body parts under or in the falling trajectory of anything heavy!

2. Wear steel-tipped safety shoes.

3. Use proper nylon slings. 1m or 2m slings rated for 1 or 2 tons are cheap on eBay, and rope is often surprisingly weak.

4. Don't be in a hurry, but think through the next move. In particular, think where the machine will end up if it slips or tilts from your ideal arrangement.

5. Use ramps to negotiate steps. If necessary, build a ramp before starting to move the machine.

6. If something is clearly still beyond the efforts of you and your pals, get the machine shipped by pallet delivery (surprisingly cheap) hire a small removal firm (man with a van) for a couple of hours to move it from your drive into your workshop. These guys are immensely strong, have the equipment and know how to move stuff. Call and explain what you want to do.

Of course I am just looking at heavy 'hobby' equipment rather than industrial machines. But there are specialist movers who will handle even these, if you really want that 2 ton super capacity machine. I hope this will stop some people being put off by the thought of installing a machine that is too heavy for them to lift.

An estate car with a lipless boot is strongly recommended!

Anyone else have moving tips to share?