I had very good success with hard wax oil on my Valchromat workbench top. The Valchromat is similar to MRMDF, but I don't know where the similarities end. However, I can tell you from experience to follow the instructions carefully, as the oil gave me a bad finish because I waited too long to wipe off the second coat and I had to repeat the final coat.

The hard wax oil is applied and left for ten minutes before wiping off the excess. After 12 hours, apply a second coat and leave it for ten minutes as well. On my workbench top, the first coat was mostly absorbed by the Valchromat and there wasn't much to wipe off. On the second coat, very little was absorbed, which meant there was a lot to wipe off.

I tried to do the entire 1x2 meter top at one time, and it didn't work out as I planned. By the time I finished applying the second coat, about 20 minutes had elapsed, and the oil started to gel to the point where I couldn't wipe it off smoothly. I waited 24 hours for the oil do dry and lightly sanded the surface with 400 grit in the random orbital sander just to the point where the top was smooth again. Then I applied a coat of the oil in smaller areas and wiped each area off after ten minutes. The finish was great.

I can't recommend a specific brand, since I don't know what is available to you, but I used semi-matte hard wax oil. I wanted matte finish, but the only choices I had were glossy and semi-matte.

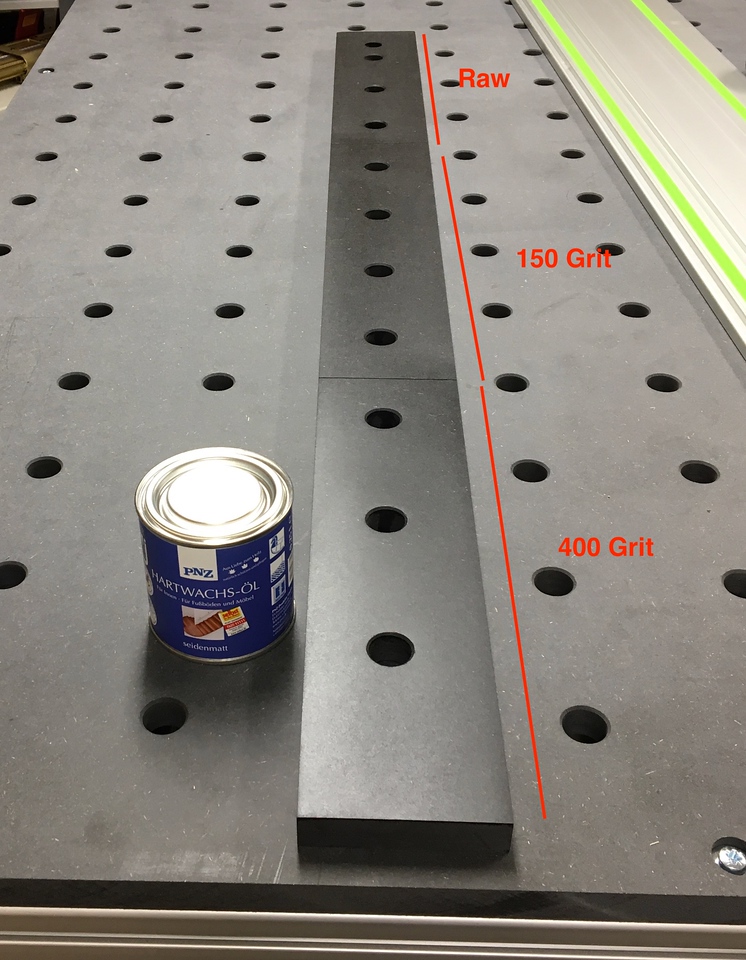

Here is what the black Valchromat sample looked like after two coats of the hard wax oil shown. The three sections of the offcut show what the surface looks like after different sanding preparation. The top section was not sanded, the middle section was sanded with 150 grit paper, and the bottom section was sanded with 150, 220, and 400 grit paper before applying the oil. I liked the look and feel of the bottom section, so that is how I prepared my workbench top. The small can in the photo was more than enough to apply three coats of oil to the workbench top, with a little left over.