So in a fit of idiocy I bought the worlds largest SCMS to go into the worlds smallest workshop.

Its the bosch GCM12 SD :

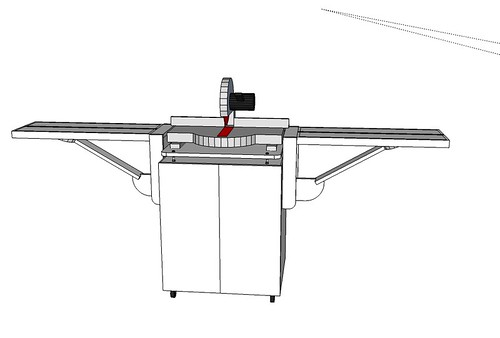

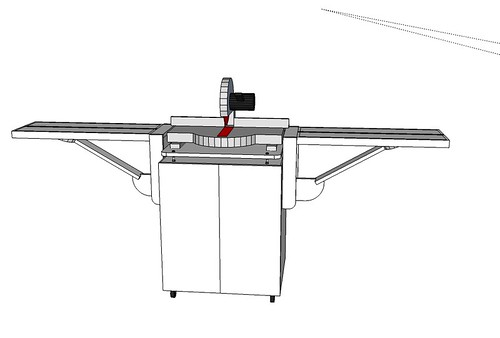

It came with the free Axminster mitre saw stand which is about 6 feet long and two and a half feet wide (so was way too big to fit in the workshop). Therefore I am building a mobile mitre stand along the lines of this :

however I am probably going to change it in two ways :

1. Put drawers in instead of cabinet doors (for better storage which is critical in my workshop)

2. Possibly not have the extension wings, instead I am building the unit to the same height as my mobile table saw stand (on this thread : https://www.ukworkshop.co.uk/forums/viewtopic.php?t=21814&postdays=0&postorder=asc&start=30

and it will also stand next to my pillar drill which has an adjustable table (so I can raise it to the same height as the mitre saw)

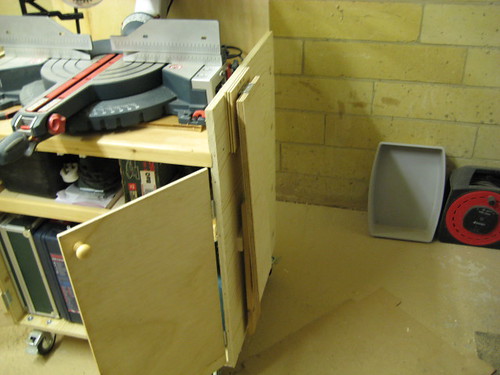

So I started tonight with some plywood for the sides and base :

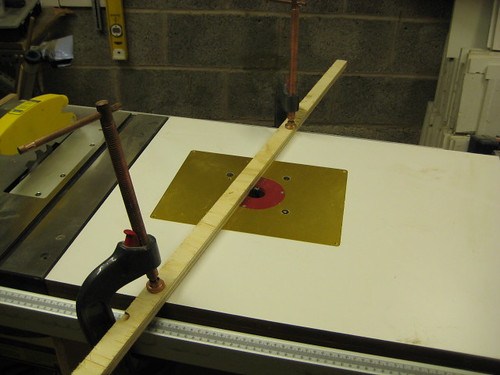

had my first attempt at proper rebates joints :

the wood cut with rebates ready to go together :

from a previous build i have a bit of kitchen counter top which was sitting going to waste. I think it will be ideal for the mitre saw to sit on (its thick, strong and flat) but it was 3cms too short, so i've glued some wood to the side to widen it, tomorrow I'll plane that down and look to rebate fit that shelf into the unit.

Its the bosch GCM12 SD :

It came with the free Axminster mitre saw stand which is about 6 feet long and two and a half feet wide (so was way too big to fit in the workshop). Therefore I am building a mobile mitre stand along the lines of this :

however I am probably going to change it in two ways :

1. Put drawers in instead of cabinet doors (for better storage which is critical in my workshop)

2. Possibly not have the extension wings, instead I am building the unit to the same height as my mobile table saw stand (on this thread : https://www.ukworkshop.co.uk/forums/viewtopic.php?t=21814&postdays=0&postorder=asc&start=30

and it will also stand next to my pillar drill which has an adjustable table (so I can raise it to the same height as the mitre saw)

So I started tonight with some plywood for the sides and base :

had my first attempt at proper rebates joints :

the wood cut with rebates ready to go together :

from a previous build i have a bit of kitchen counter top which was sitting going to waste. I think it will be ideal for the mitre saw to sit on (its thick, strong and flat) but it was 3cms too short, so i've glued some wood to the side to widen it, tomorrow I'll plane that down and look to rebate fit that shelf into the unit.