devonwoody

Established Member

Having a break from the lazy susan for a few days but started a sled to cut mitres only with the new tablesaw.

I have some old laboratory doors which have been veneered over batten constructed boards, I cant recall what the correct term is at the moment, also edged with mahogany. These doors are over 50 years old but completely flat and corners are square.

Some roof timbers are being used for the fence crossbars (again over 50 years and only needed cleaning up and also square.

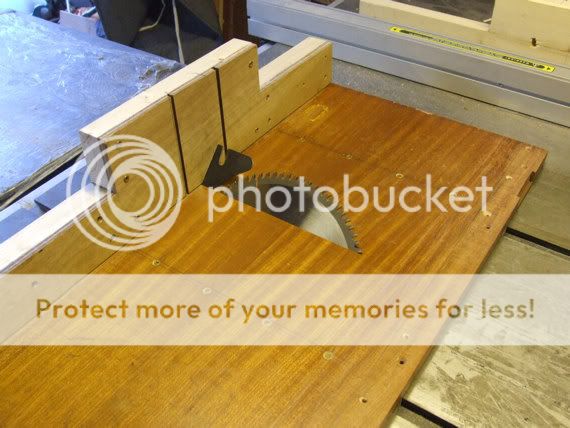

First picture shows a cross bar under construction

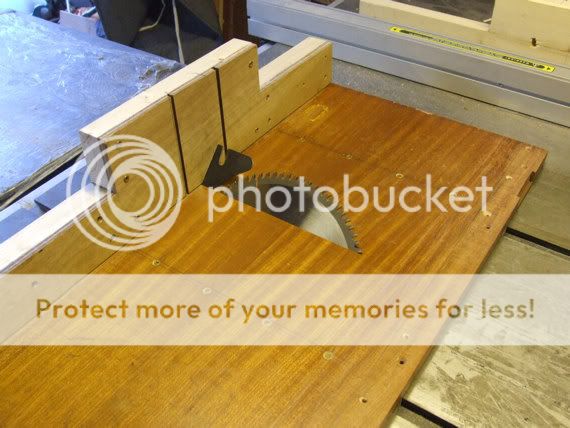

Second pic. I have attached the crossbar glued and screwed but leaving to cure in the conservatory because we have a cold snap down here at the moment and want the glue to mature.

In the following photographs I have machined grooves for the Perspex guard and also run the tablesaw blade (80tooth perform freebie) 75% across the sled only.

The reason for this is so that I can set the second fence at 90% more accurately to the saw line, and will complete the cut at a later time when fence has been glued to the correct position.

Main hold fence is now being glued into position with some screws also holding beneath board.

I have made an addition to other sleds previously seen on forums by cutting a slot in the rear fence which will enable a bar cramp to be passed through when operating the sled I have removed the dimple at the end of a clamp so that the head can come away from the winder bar. This of course is as yet untried but will keep you informed if it is a success.

To lubricate the somooth running of the sled across the c.i. table I have applied beeswax to runners/slots base of sled and ci table top, in fact the wax is so affective I am hanging on to the board to stop it flying out of the workshop door. Thank you Adam again.

I have some old laboratory doors which have been veneered over batten constructed boards, I cant recall what the correct term is at the moment, also edged with mahogany. These doors are over 50 years old but completely flat and corners are square.

Some roof timbers are being used for the fence crossbars (again over 50 years and only needed cleaning up and also square.

First picture shows a cross bar under construction

Second pic. I have attached the crossbar glued and screwed but leaving to cure in the conservatory because we have a cold snap down here at the moment and want the glue to mature.

In the following photographs I have machined grooves for the Perspex guard and also run the tablesaw blade (80tooth perform freebie) 75% across the sled only.

The reason for this is so that I can set the second fence at 90% more accurately to the saw line, and will complete the cut at a later time when fence has been glued to the correct position.

Main hold fence is now being glued into position with some screws also holding beneath board.

I have made an addition to other sleds previously seen on forums by cutting a slot in the rear fence which will enable a bar cramp to be passed through when operating the sled I have removed the dimple at the end of a clamp so that the head can come away from the winder bar. This of course is as yet untried but will keep you informed if it is a success.

To lubricate the somooth running of the sled across the c.i. table I have applied beeswax to runners/slots base of sled and ci table top, in fact the wax is so affective I am hanging on to the board to stop it flying out of the workshop door. Thank you Adam again.