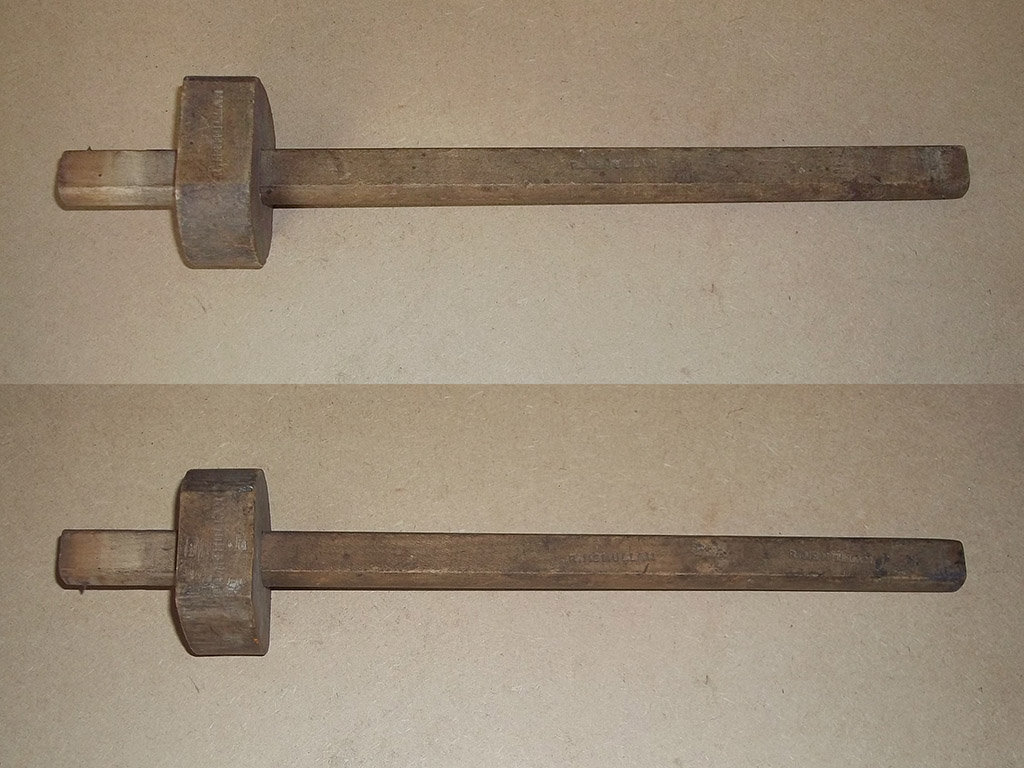

Come across a few of these over the years and thought I was missing something but it did eventually dawn on me that there wasn't anything missing and they were made to rely on a tight fit between fence and stem. Obviously this could lead to a problem come a change of season and almost all I've handled were stuck fast from the damp conditions they were now stored in.

I've always passed on them as I didn't want to pay really anything for something that might turn out to be too loose for half the year or too tight for the other half, but I had the chance to pick up the below one recently from a seller I buy from regularly and I knew it would be cheap as chips so I'd be all right with it becoming a decorative piece for the workshop if it turned out to be hopelessly jammed.

I have always assumed these are user-made but does anyone know if there were commercial versions?

If this is homemade then respect to R.McMullan, he did a super job shaping the stem and chiselling the mortise to match. I was surprised however with that level of skill that there was tearout on multiple surfaces. But apparently that could be much more acceptable in the past than it is generally now.

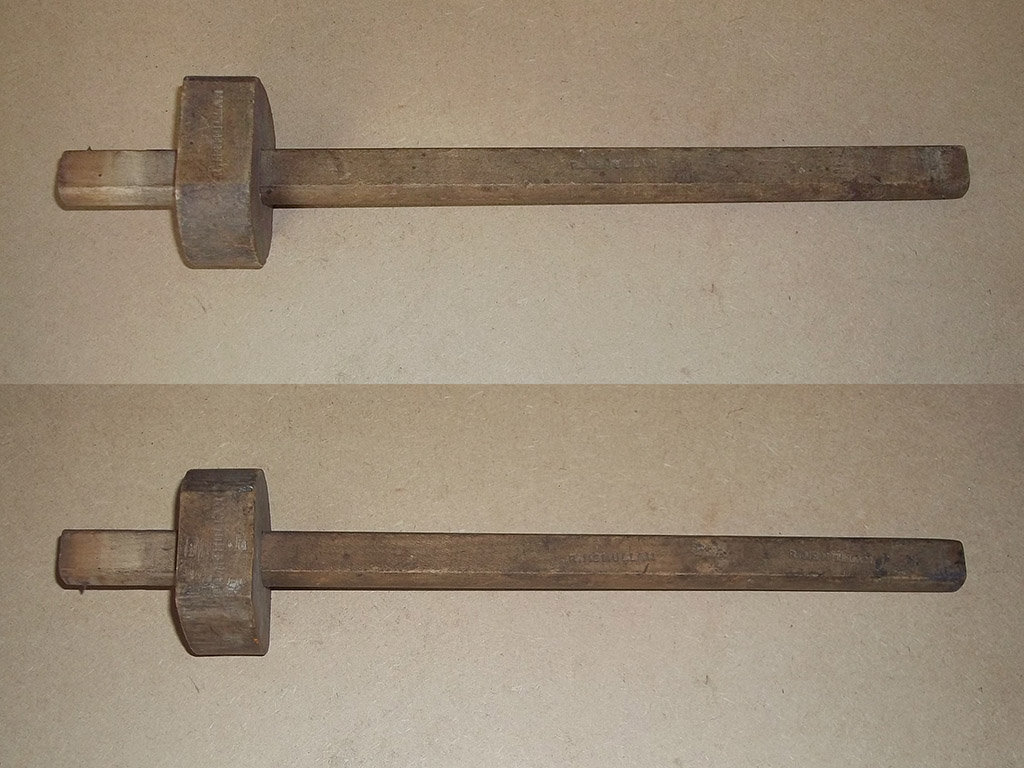

I've always passed on them as I didn't want to pay really anything for something that might turn out to be too loose for half the year or too tight for the other half, but I had the chance to pick up the below one recently from a seller I buy from regularly and I knew it would be cheap as chips so I'd be all right with it becoming a decorative piece for the workshop if it turned out to be hopelessly jammed.

I have always assumed these are user-made but does anyone know if there were commercial versions?

If this is homemade then respect to R.McMullan, he did a super job shaping the stem and chiselling the mortise to match. I was surprised however with that level of skill that there was tearout on multiple surfaces. But apparently that could be much more acceptable in the past than it is generally now.