You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

making thin strips flat

- Thread starter sunnybob

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I'm taking one step forwards and two steps back here.

I made a ply base with thin strips of hardwood to act as guides. I can see how it would work for most, but i just cant get the plane to do whats its supposed to. Either it takes no wood off, or I have to repeatedly ram the plane across the wood (oak) and the plane skews sideways under the force I'm using. I've just turned one of my ragged but flat strips into a 600m wide wedge. i just cannot plane the wood square.

looks like the vice is on the back burner, and the planer thicknesser has just reached top of the wish list.

I made a ply base with thin strips of hardwood to act as guides. I can see how it would work for most, but i just cant get the plane to do whats its supposed to. Either it takes no wood off, or I have to repeatedly ram the plane across the wood (oak) and the plane skews sideways under the force I'm using. I've just turned one of my ragged but flat strips into a 600m wide wedge. i just cannot plane the wood square.

looks like the vice is on the back burner, and the planer thicknesser has just reached top of the wish list.

Paul Chapman

Established Member

You seem to be making a meal of this. Setting up a plane and planing a piece of wood is a very basic woodworking skill. If you don't know how to do it, buying a planer thicknesser is not really the answer - in fact it will probably give you even more problems. There are plenty of DVDs available from people like David Savage and David Charlesworth which will show you how to do it. Alternatively, if you have any friends who are woodworkers why not ask them to show you how when you visit the UK?

Cheers :wink:

Paul

Cheers :wink:

Paul

Paul Chapman":38wv43e5 said:Setting up a plane and planing a piece of wood is a very basic woodworking skill.

Conversely: setting up a plane and planing a piece of wood is also not immediately easy and there are a lot of not-so-obvious things that can go wrong. Planing thin strips that aren't properly clamped is going to be harder than planing larger pieces of wood which are firmly held in place, so if you're having trouble with the plane in general, I'd recommend skipping the thin strips for now and getting some practice in on larger, vice-held pieces. And practice on softer woods, they plane a lot easier and usually have easier grain!

Also a thicknesser will only allow you to make strips so thin anyway, it works better on larger pieces too. ;-)

When I first tried hand-planing I found it the most frustrating exercise, and almost gave up before I'd started. Getting hold of a decent quality plane (second hand Record), sharpening the blade properly, waxing the sole and learning how to adjust it decently, deal with backlash and blade tilt and most importantly read the direction of the grain made a huge difference and it now feels easy... but it took a lot of learning.

custard

Established Member

sunnybob":s7t1wunp said:I'm taking one step forwards and two steps back here.

I made a ply base with thin strips of hardwood to act as guides. I can see how it would work for most, but i just cant get the plane to do whats its supposed to. Either it takes no wood off, or I have to repeatedly ram the plane across the wood (oak) and the plane skews sideways under the force I'm using. I've just turned one of my ragged but flat strips into a 600m wide wedge. i just cannot plane the wood square.

looks like the vice is on the back burner, and the planer thicknesser has just reached top of the wish list.

I bet lots of hobbyist woodworkers do exactly the same thing, hit a hand tool snag and reach for a powered solution. It's not always a mistake...but it's usually a mistake...and in this case it's definitely a mistake. Because if you can't set up and use a hand plane then your woodworking career is pretty much over.

As Paul said when it comes to fixing this there are plenty of options open to you, so there's no need to despair. But you should put whatever project you've been working on to one side, and just focus on hand planing until you've achieved some basic competency, then pick up the project again.

Get yourself a piece of knot free pine, or poplar, or American cherry; anything in fact so long as it's fairly mild to work and is fairly straight grained. And with that fastened in your vice or held to your bench against a planing stop just work through your planing process step by basic step until you can confidently smooth and flatten the wood.

Is the blade sharp? Is the frog firmly screwed to the plane body? Is the cap iron tight to the blade? There is a solution to the problem, and even if it's not obvious to you right now I assure you the solution is there. But the solution absolutely is not some cheap and badly made planer thicknesser that will only bring a whole fresh set of frustrations.

Good luck!

Ed Bray

Established Member

I don't know why you haven't tried my method, you could build it in about 10 minutes. In fact, I will go out in a minute and build one just to see actually how long it takes.

7 bits of wood, three for the frame, 2 for the runners and one for the end and a shim to plane to (plus some further shims for adjusting the thickness, you can add these later as required).

The plane can't skew because the frame is sized to the width of it, you can't cut a wedge (unless you want to and that would mean installing a wedge as a shim) because the runners stop you cutting when you 'get to depth'

You do need to be able to set up a plane though, although there are plenty of methods on youtube as examples.

I'll post some pictures of my effort in a short while.

7 bits of wood, three for the frame, 2 for the runners and one for the end and a shim to plane to (plus some further shims for adjusting the thickness, you can add these later as required).

The plane can't skew because the frame is sized to the width of it, you can't cut a wedge (unless you want to and that would mean installing a wedge as a shim) because the runners stop you cutting when you 'get to depth'

You do need to be able to set up a plane though, although there are plenty of methods on youtube as examples.

I'll post some pictures of my effort in a short while.

£238.91

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

custard

Established Member

Ed Bray":3c5ch1c4 said:I don't know why you haven't tried my method, you could build it in about 10 minutes. In fact, I will go out in a minute and build one just to see actually how long it takes.

7 bits of wood, three for the frame, 2 for the runners and one for the end and a shim to plane to (plus some further shims for adjusting the thickness, you can add these later as required).

The plane can't skew because the frame is sized to the width of it, you can't cut a wedge (unless you want to and that would mean installing a wedge as a shim) because the runners stop you cutting when you 'get to depth'

You do need to be able to set up a plane though, although there are plenty of methods on youtube as examples.

I'll post some pictures of my effort in a short while.

Ed, pound to a penny the problem is that the plane's not been set up right, so all the jigs and work holding fixtures in the world are pretty much redundant until that's sorted out.

Ed Bray

Established Member

I have to confess, it did take a bit longer than 10 minutes, about an hour or so, it only took 10 inutes once I had found and sized all the wood and got all my fixings and glue together. Taking photos didn't help but I tried to discount the time that they took.

Things I discovered:

Not all plane bodies are the same width. I original measured my Stanley 5½ which had a sole of 75½mm width, I subsequently measured both my No 4½s (a Stanley and a Veritas), three No 6s (a Stanley, Record and Woodriver) and my No 7 (Quangsheng) and they were all between 73mm and 74mm. I eventually sized the jig at 74mm width.

One side of the jig needs to be lower than the other. I measures the sides at 75mm high but the Mahogany runners ended up at 42mm which meant I had 33mm height above the runners, whilst this was good for support, it meant my right hand was running along the top of the jig. I chopped it down by 13mm leaving 20mm above the runners on the right side (left handers would need to down the left side a bit).

I did need to put a small bit of wood at the open end just to stop the jig splaying slightly in use.

Sizes of box is 860mm long, 110mm wide, 75mm high left side, 62mm high right side (all from 18mm exterior grade plywood), runners were sized at 860mm long x 42mm tall x 8mm wide. Oak piece on end was 110mm wide by 60mm high x 20mm wide, oak offcut on other end was 110mm x 22mm x 20mm.

Sole of No 6 which also game me the size for the runners of 8mm

Mahogany runners.

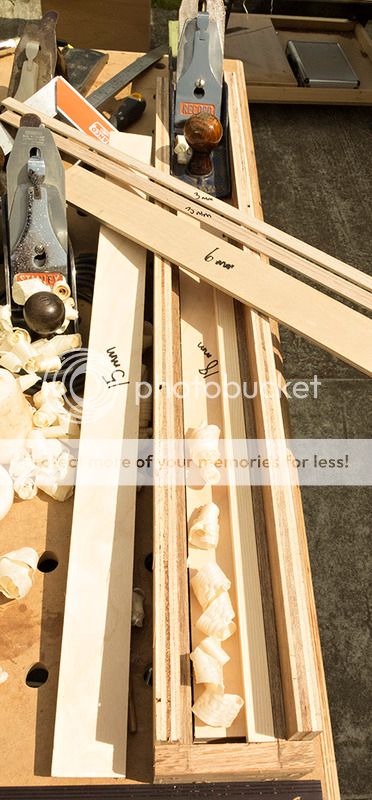

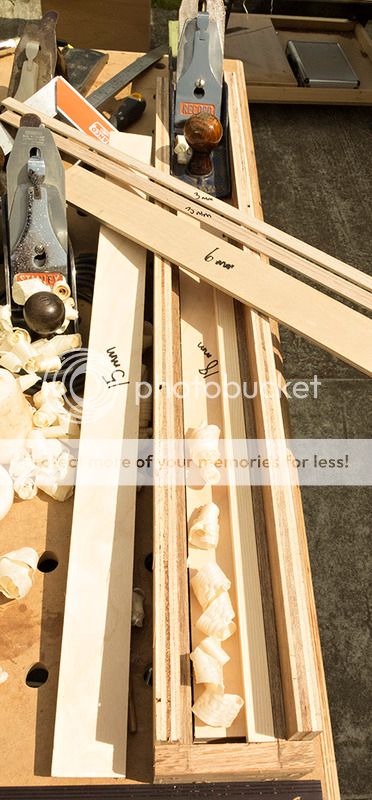

Wood all dimensioned

Box before brace added at end and right side wall cut down.

Completed box, just need to make some shims now.

Made some quick shims out of some Birch Ply I had around, 2x 3mm slices, 2x 6mm, 1x 15mm and 1x 18mm. Tried it out with the 3mm shims and 18mm together which meant that I was taking the wood down to 21mm. I did this on two sides, then I removed the 2x 3mm shims and added a 6mm shim making the total then 24mm giving a finished size of 18mm. I then surfaced the other 2 sides which then gave a lovely finished piece exactly 18mm square, and with a much better finish than from my mechanical planer/thicknesser.

Things I discovered:

Not all plane bodies are the same width. I original measured my Stanley 5½ which had a sole of 75½mm width, I subsequently measured both my No 4½s (a Stanley and a Veritas), three No 6s (a Stanley, Record and Woodriver) and my No 7 (Quangsheng) and they were all between 73mm and 74mm. I eventually sized the jig at 74mm width.

One side of the jig needs to be lower than the other. I measures the sides at 75mm high but the Mahogany runners ended up at 42mm which meant I had 33mm height above the runners, whilst this was good for support, it meant my right hand was running along the top of the jig. I chopped it down by 13mm leaving 20mm above the runners on the right side (left handers would need to down the left side a bit).

I did need to put a small bit of wood at the open end just to stop the jig splaying slightly in use.

Sizes of box is 860mm long, 110mm wide, 75mm high left side, 62mm high right side (all from 18mm exterior grade plywood), runners were sized at 860mm long x 42mm tall x 8mm wide. Oak piece on end was 110mm wide by 60mm high x 20mm wide, oak offcut on other end was 110mm x 22mm x 20mm.

Sole of No 6 which also game me the size for the runners of 8mm

Mahogany runners.

Wood all dimensioned

Box before brace added at end and right side wall cut down.

Completed box, just need to make some shims now.

Made some quick shims out of some Birch Ply I had around, 2x 3mm slices, 2x 6mm, 1x 15mm and 1x 18mm. Tried it out with the 3mm shims and 18mm together which meant that I was taking the wood down to 21mm. I did this on two sides, then I removed the 2x 3mm shims and added a 6mm shim making the total then 24mm giving a finished size of 18mm. I then surfaced the other 2 sides which then gave a lovely finished piece exactly 18mm square, and with a much better finish than from my mechanical planer/thicknesser.

Ed, I really appreciate the time youve taken to show me what you mean. I now understand what youre doing, but my skills are so low that making the shims is not going to be easy for me. I walked away in disgust today. I shall have time again Tuesday, I shall see if I can make a box (but you realise boxes are made from flat pieces?)

Custard also, I think you understand just how frustrated I am. I have been unable to find any one on this island who makes small wood things as a hobby. I have even advertised island wide, and got zero response. i only know one wood worker in the uk, and he's a lathe man so I have nobody to help me, and the internet is the only source of information I have.

I thought I had the plane blades sharp, i've followed several you tubes on the subject. They have been working ok on ply edges and softwood, but against this oak, not a hope.

Oh well, Tuesday is another day.

Custard also, I think you understand just how frustrated I am. I have been unable to find any one on this island who makes small wood things as a hobby. I have even advertised island wide, and got zero response. i only know one wood worker in the uk, and he's a lathe man so I have nobody to help me, and the internet is the only source of information I have.

I thought I had the plane blades sharp, i've followed several you tubes on the subject. They have been working ok on ply edges and softwood, but against this oak, not a hope.

Oh well, Tuesday is another day.

custard

Established Member

sunnybob":12o2rjqt said:I have been unable to find any one on this island who makes small wood things as a hobby. I have even advertised island wide, and got zero response. i only know one wood worker in the uk, and he's a lathe man so I have nobody to help me, and the internet is the only source of information I have.

I thought I had the plane blades sharp, i've followed several you tubes on the subject. They have been working ok on ply edges and softwood, but against this oak, not a hope.

That's tough Bob, it's difficult without anyone to help and to be honest the internet is as much a hindrance as a help, you get a million contradictory bits of advice often from people who often have very little practical experience but have read a book or two and enjoy spouting off.

I suspect your plane might not be as sharp as you think it is. In all the waffle that get's talked about sharpening on the internet one fact seems to get overlooked, woodworking with hardwoods means you spend a great deal of time sharpening. Sharpening isn't something you do once a week or just at the start of the day, for the handtool woodworker it's something you're doing again and again, each and every day. A plane will probably need re-honing after only 10-15 minutes constant use on a hard timber like oak. I'll say that again because it comes as a bit of a shock to many hobbyists, constant planing on a tough timber means that after just ten or fifteen minutes the increased effort in pushing the plane and the increased risk of tear out means you should stop and re-hone the blade. Sure, if you've got some super duper powdered steel tool or you're working in knot free pine then you might go a bit longer, but equally if you're using the original thin blades in a Record or Stanley and your wood is particularly intractable then you'll get even less time.

So it's a banker's bet that your plane blade needs sharpening!

Now I don't know what sharpening method you use, and I don't particularly care, but one thing you absolutely must do is check that you're raising a burr. No burr means you just keep on at the coarse stone until there is a burr and you can feel it right across the entire blade. Skip that stage and there's every chance that instead of actually sharpening you're just fooling yourself that your tools are sharp.

Good luck!

Ed Bray

Established Member

Hi Bob, I just used plywood for the base and sides and shims, you could even use plywood for the runners, the blade on the plane will cut its own channel. I did use some hardwood strips for my runners but then I do have access to a good table saw and SC mitre saw (along with a good selection of wood).

After a lifetime working with metal, I thought wood would be an easy hobby. I'm discovering just how wrong that idea was. i've spent so much time in the last 8 months just walking away and wondering if I should quit.

I am very grateful to the two of you for sticking with me and trying to educate me. I shant rush to buy any more power tools (phew, says my wife). I shall have to have a reflective period and decide just what I really want.

thanks again.

I am very grateful to the two of you for sticking with me and trying to educate me. I shant rush to buy any more power tools (phew, says my wife). I shall have to have a reflective period and decide just what I really want.

thanks again.

Droogs

Not the Sharpest Moderator in the box

Sunnbob,

don't give up. all it takes is practice of the basics and then it becomes ingrained. think aboout when you learned to weld metal and the snotters you made then and the seams now. The same with wood only more so. Start by learning to plane to square and then to a thickness and after that you'll probably learn to enjoy it :lol:

don't give up. all it takes is practice of the basics and then it becomes ingrained. think aboout when you learned to weld metal and the snotters you made then and the seams now. The same with wood only more so. Start by learning to plane to square and then to a thickness and after that you'll probably learn to enjoy it :lol:

Droogs

Not the Sharpest Moderator in the box

Don't know if your're anywhere near Nicosia but you could try these guys as a starting point

Cyprus furniture and woodworking association

2 Acropoleos Ave. & Glafkou, Strovolos.

P.O.BOX 2157, 1511 Nicosia

Or enven maybe contact this guy;

http://www.instructables.com/id/The-Sma ... the-World/

Cyprus furniture and woodworking association

2 Acropoleos Ave. & Glafkou, Strovolos.

P.O.BOX 2157, 1511 Nicosia

Or enven maybe contact this guy;

http://www.instructables.com/id/The-Sma ... the-World/

Droogs, i think I will downsize my aspirations, and go back to working soft wood for a while. I am obviously way out of my league with this oak.

I had some minor successes with mahogany when I started, I shall go back to it and stay away from hard woods.

Nicosia is a good hour on the motorway from me. I had seen the guy with the mobile work bench, but not the woodworking association. I shall contact them, thanks very much. I have tried to find evening classes here, but the language barrier is huge when dealing with ordinary workers. My greek barely passes the "good morning, & two beers please" level.

I had some minor successes with mahogany when I started, I shall go back to it and stay away from hard woods.

Nicosia is a good hour on the motorway from me. I had seen the guy with the mobile work bench, but not the woodworking association. I shall contact them, thanks very much. I have tried to find evening classes here, but the language barrier is huge when dealing with ordinary workers. My greek barely passes the "good morning, & two beers please" level.

Droogs

Not the Sharpest Moderator in the box

Just one last place I can think of is the Cyprus handicraft ministry museum and workshops Athalassa Avenue in Lefkosia, near the junction of the Lefkosia - Lemesos highway

http://www.mcit.gov.cy/mcit/chs/chs.nsf ... enDocument

Hope this is helpful they seem to have a woodworking workshop that runs training

http://www.mcit.gov.cy/mcit/chs/chs.nsf ... enDocument

Hope this is helpful they seem to have a woodworking workshop that runs training

where are you finding this stuff? your search engine is vastly superior to mine.

I've just looked that up and I even know where it is. Its in the same street as a shop that has a lot of woodwork tools (no, the owner of the shop couldnt help me). i knew it was a folk centre, but did not know it had a wood work shop.

thanks again

I've just looked that up and I even know where it is. Its in the same street as a shop that has a lot of woodwork tools (no, the owner of the shop couldnt help me). i knew it was a folk centre, but did not know it had a wood work shop.

thanks again

rafezetter

Troll Hunter

Heres a dandy jig for handplane thicknessing, and construction doesn't look so complicated:

In use:

https://www.youtube.com/watch?v=l4FIur6_Q68

Construction:

https://www.youtube.com/watch?v=RQVw82ofqqs

In use:

https://www.youtube.com/watch?v=l4FIur6_Q68

Construction:

https://www.youtube.com/watch?v=RQVw82ofqqs

rafezetter

Troll Hunter

sunnybob":2ljm9ryg said:Droogs, i think I will downsize my aspirations, and go back to working soft wood for a while. I am obviously way out of my league with this oak.

I had some minor successes with mahogany when I started, I shall go back to it and stay away from hard woods.

Nicosia is a good hour on the motorway from me. I had seen the guy with the mobile work bench, but not the woodworking association. I shall contact them, thanks very much. I have tried to find evening classes here, but the language barrier is huge when dealing with ordinary workers. My greek barely passes the "good morning, & two beers please" level.

From recent personal experience you will find that working oak and "normal" hardwoods is easier than softwoods because you get much crisper cuts with less possibility of tearout with things like dovetails, mortices and such. I thought too that softwood was simpler, but in reality it brings it's own set of problems.

If you need cheap wood to practise on you might be surprised to learn that many pallets actually have hardwood slats on them, not necessarily all of them, but I've seen many pallets with the odd one or two hardwood slats - after all it's just rough offcut wood. Once you learn to recognise them you'll see them all over.

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 7

- Views

- 743

- Replies

- 9

- Views

- 3K