curtisrider

Established Member

I have been on a bit of a mission trying to sort out my saws as i'm gradually doing smaller and finer stuff and becoming increasingly aware just how important a finely tuned saw is! I have three budget machines that I can't really justify replacing at the moment and I know with some tweaking that they will be perfectly good enough as a stepping stone until funds allow them to be replaced so please don't just reply with 'they are rubbish mate, sell your house and buy this'. I just want to get the most out of what I have got until funds allow and also my skills can justify better equipment.

I currently have the following machines and questions to suit:

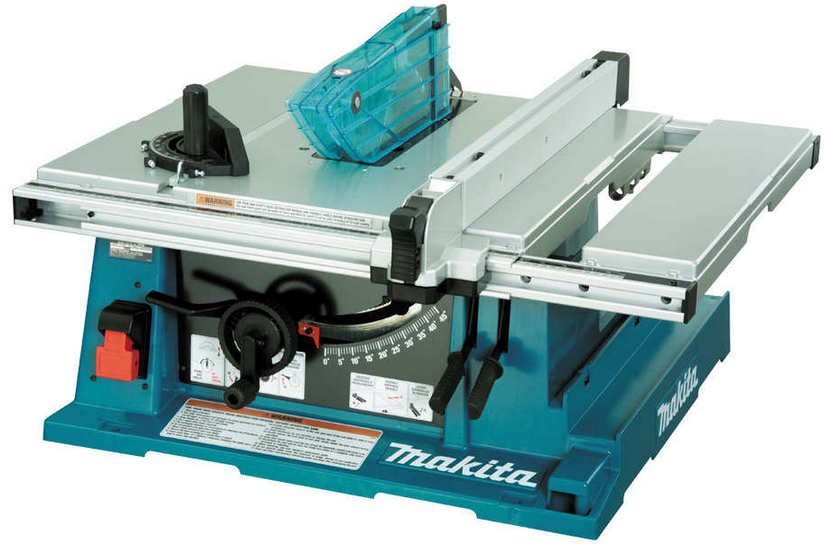

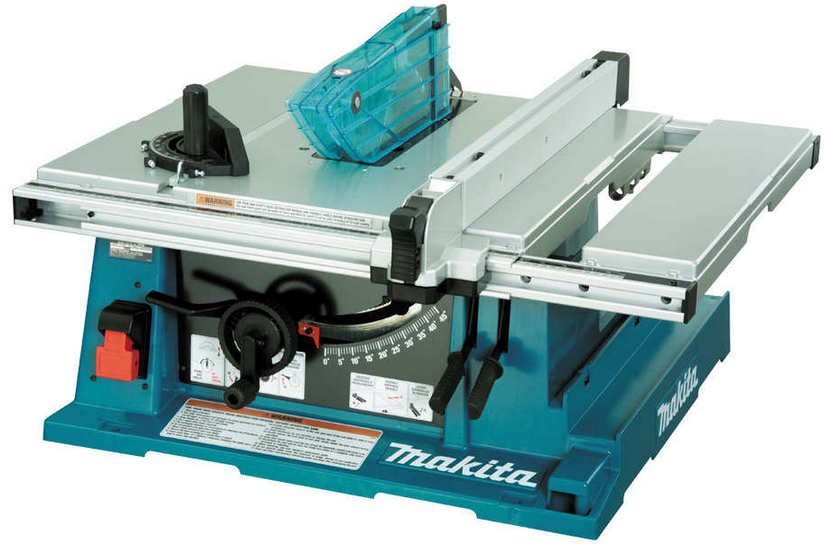

1. Makita 2704

I bought one of these for a tenner as the motor was shot, £150 later for parts and I have rebuilt it back to its former glory. I know it's just a contractors saw (although their top end one at the time) and ideally I would have a proper workshop saw with a cast table but that doesn't fit my budget right now. I have ditched the old worn out Makita blade for a Freud 250mm 40T blade which has improved the cuts no end, it's fairly general purpose but I can always buy an extra blade with a finer cut if I need to later. I have also built a crosscut sled which has proved to be very useful, I will make an improved one at some point as this one is just from the limited scrap I had kicking about.

As you can see the riving knife is huge, I may have to make/adapt a slightly smaller one for when the sled is in use.

My main issue with this saw is the fence design, the current one works and holds fine but it is a bit of a swine to adjust accurately as the fence doesn't always sit parallel to the blade so you have to fiddle about with it which is not ideal when you are trying to do lots of quick cuts.

So my questions for this saw are what sort of fence system would you recommend as a replacement (preferably DIY if possible) or how can I make the most of the current fence? Also the blade guard works fine but does not allow extraction, can I simply just add a port to it or is there an aftermarket guard I can fit in order to maintain safety and keep my workspace clean?

2. Woodwise 14" bandsaw

I bought this for £130 and it seems to have barely been used by the previous owner. This seems to be a fairly generic cast construction 14" bandsaw and looks like it shares parts with many others on the market. I have tuned it up as per some guides online which has improved the saw massively, I also have a selection of blades for difference purposes.

The gearing is quite low compared to others I have used and it is quite slow to cut due to this, should I look into upgrading the 2 speed set up to the multi speed setups that other saws seem to have? I also considered fitting a higher HP motor at the same time, I'm fairly sure I have one tucked away that will fit, I'll just need to make sure the current switch and wiring can handle it.

The fence on this is really appalling as it is very limited in its range and it can't be adjusted as it is to ensure it is paralell to the mitre slot. I have found the table size is too small when working with larger pieces. I want to at the very least fit a new fence but i'm not sure which design to use/make. I saw this on youtube and it seems to be a cheap and decent design that isn't going to be hard to make:

https://www.youtube.com/watch?v=Q_fzKmbV14I

But that leaves me with a small table still, so I found this which is also another possibility as I have a spare mitre gauge kicking about:

https://www.youtube.com/watch?v=nCyzX6NBCFU

3. Evolution rage sliding compound saw 210mm

I know what you're all already thinking, why why why? I bought this when I was doing up my house and it was very useful for lots of the first fix tasks and manageable but not ideal for second fix. I have spent some time tweaking it out of the box to get it cutting straight and it's now as accurate as it can be, fortunately mine doesn't suffer the wobble that others seem to have which helps massively. I have got to the point where the blade is tired and drifts a bit as well as burning. I have bought a washer to take it from 25.4mm to 30mm opening up the range of blades that I can fit. I am thinking of ordering a Freud 216x30 48t blade, I have measured for clearance as this blade is overall 6mm larger in diameter (of course the 3mm increase in radius is what I have checked for when noting clearance), this should be a suitable blade for the majority of the jobs I do.

Is there much else I can do to get the best out of this until I can justify a better quality unit? I will keep this with a multipurpose blade on in the future as it is still a handy machine for jobs where fine accuracy isn't as important.

Any help would be greatly appreciated, I appreciate that I have bombarded you all with lots of questions here!

I currently have the following machines and questions to suit:

1. Makita 2704

I bought one of these for a tenner as the motor was shot, £150 later for parts and I have rebuilt it back to its former glory. I know it's just a contractors saw (although their top end one at the time) and ideally I would have a proper workshop saw with a cast table but that doesn't fit my budget right now. I have ditched the old worn out Makita blade for a Freud 250mm 40T blade which has improved the cuts no end, it's fairly general purpose but I can always buy an extra blade with a finer cut if I need to later. I have also built a crosscut sled which has proved to be very useful, I will make an improved one at some point as this one is just from the limited scrap I had kicking about.

As you can see the riving knife is huge, I may have to make/adapt a slightly smaller one for when the sled is in use.

My main issue with this saw is the fence design, the current one works and holds fine but it is a bit of a swine to adjust accurately as the fence doesn't always sit parallel to the blade so you have to fiddle about with it which is not ideal when you are trying to do lots of quick cuts.

So my questions for this saw are what sort of fence system would you recommend as a replacement (preferably DIY if possible) or how can I make the most of the current fence? Also the blade guard works fine but does not allow extraction, can I simply just add a port to it or is there an aftermarket guard I can fit in order to maintain safety and keep my workspace clean?

2. Woodwise 14" bandsaw

I bought this for £130 and it seems to have barely been used by the previous owner. This seems to be a fairly generic cast construction 14" bandsaw and looks like it shares parts with many others on the market. I have tuned it up as per some guides online which has improved the saw massively, I also have a selection of blades for difference purposes.

The gearing is quite low compared to others I have used and it is quite slow to cut due to this, should I look into upgrading the 2 speed set up to the multi speed setups that other saws seem to have? I also considered fitting a higher HP motor at the same time, I'm fairly sure I have one tucked away that will fit, I'll just need to make sure the current switch and wiring can handle it.

The fence on this is really appalling as it is very limited in its range and it can't be adjusted as it is to ensure it is paralell to the mitre slot. I have found the table size is too small when working with larger pieces. I want to at the very least fit a new fence but i'm not sure which design to use/make. I saw this on youtube and it seems to be a cheap and decent design that isn't going to be hard to make:

https://www.youtube.com/watch?v=Q_fzKmbV14I

But that leaves me with a small table still, so I found this which is also another possibility as I have a spare mitre gauge kicking about:

https://www.youtube.com/watch?v=nCyzX6NBCFU

3. Evolution rage sliding compound saw 210mm

I know what you're all already thinking, why why why? I bought this when I was doing up my house and it was very useful for lots of the first fix tasks and manageable but not ideal for second fix. I have spent some time tweaking it out of the box to get it cutting straight and it's now as accurate as it can be, fortunately mine doesn't suffer the wobble that others seem to have which helps massively. I have got to the point where the blade is tired and drifts a bit as well as burning. I have bought a washer to take it from 25.4mm to 30mm opening up the range of blades that I can fit. I am thinking of ordering a Freud 216x30 48t blade, I have measured for clearance as this blade is overall 6mm larger in diameter (of course the 3mm increase in radius is what I have checked for when noting clearance), this should be a suitable blade for the majority of the jobs I do.

Is there much else I can do to get the best out of this until I can justify a better quality unit? I will keep this with a multipurpose blade on in the future as it is still a handy machine for jobs where fine accuracy isn't as important.

Any help would be greatly appreciated, I appreciate that I have bombarded you all with lots of questions here!