paulm

IG paulm_outdoors

Paul Chapman came over to my place today to have his first hands on turning session, and to knock up a LN knock off :shock: :lol:

The rather fetching turning smock is one of my old ones to keep shirt sleeves and the like safely out of harms way, sorry it wasn't a bit more fashionable Paul !

Have to say that Paul took to it like a duck to water, picked it up very quickly, and after a couple of practice pieces and a break for lunch and a coffee launched into the real thing using a spare piece of cherry I had in the workshop.

Here's some action shots of the master at work

Final stages

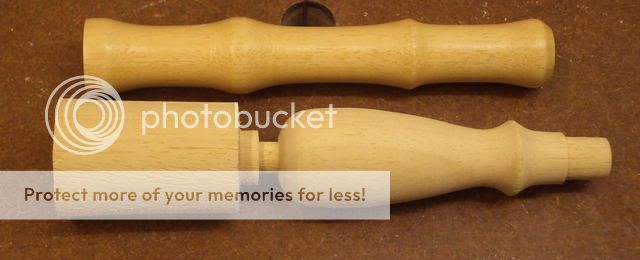

Finished article

Here's a group shot of the genuine LN article at the top in curly maple, then an earlier effort of mine in pau rosa (nice and heavy, gives a good weight to it), Paul's cherry version from today and a she oak version I made before that Paul has now had for a while and that gave him the urge to try making one for himself.

I think it was a first class effort for Paul on his first turning session and an excellent result, not much to choose between any of them and the LN original !

And thanks for the replacement Y lever for my converted Stanley scrub plane Paul, now duly rehabilitated and due to be given a bit of a workout tomorrow

A fun day and productive too, back to gardening duties tomorrow though unfortunately

Cheers, Paul

The rather fetching turning smock is one of my old ones to keep shirt sleeves and the like safely out of harms way, sorry it wasn't a bit more fashionable Paul !

Have to say that Paul took to it like a duck to water, picked it up very quickly, and after a couple of practice pieces and a break for lunch and a coffee launched into the real thing using a spare piece of cherry I had in the workshop.

Here's some action shots of the master at work

Final stages

Finished article

Here's a group shot of the genuine LN article at the top in curly maple, then an earlier effort of mine in pau rosa (nice and heavy, gives a good weight to it), Paul's cherry version from today and a she oak version I made before that Paul has now had for a while and that gave him the urge to try making one for himself.

I think it was a first class effort for Paul on his first turning session and an excellent result, not much to choose between any of them and the LN original !

And thanks for the replacement Y lever for my converted Stanley scrub plane Paul, now duly rehabilitated and due to be given a bit of a workout tomorrow

A fun day and productive too, back to gardening duties tomorrow though unfortunately

Cheers, Paul