devonwoody

Established Member

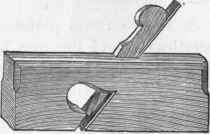

As anyone here made a wooden version of the Record 073 shoulder plane, or have pictures of early wooden hand planes of this nature?

AndyT":14nolnbl said:A few clicks away from the ECE plane that Pete linked to is this interesting example of a low angle wooden plane with a full width blade:

AndyT":3h51h4jr said:which perhaps shows that exotic hardwoods can be used for designs where English beech would have failed.

bugbear":1vnp7z3n said:Since (according to LV, LN and DC *) <snip>

(*) if you understand this, you've been spending too much on this forum.

Enter your email address to join: