jimi43

Established Member

I have been looking for a lathe to replace my little ML1 for ages...something where I spend more time working on metal than the lathe itself (much though I love my old 30s Myford!)

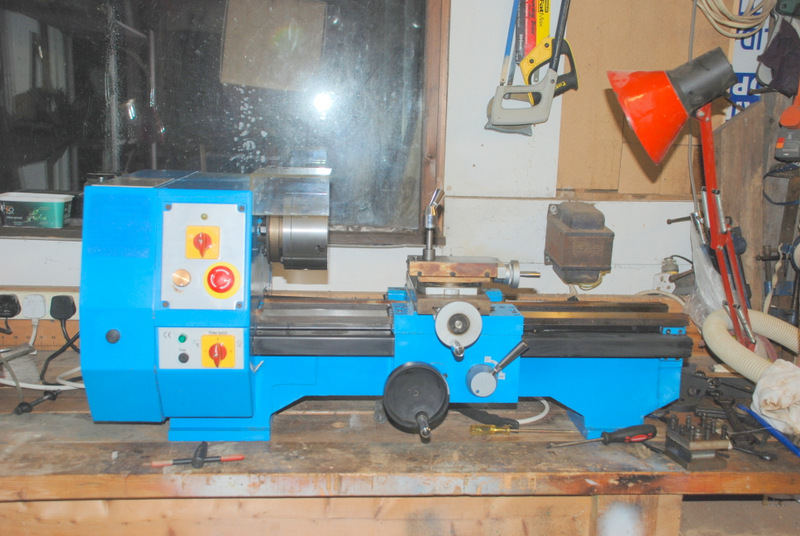

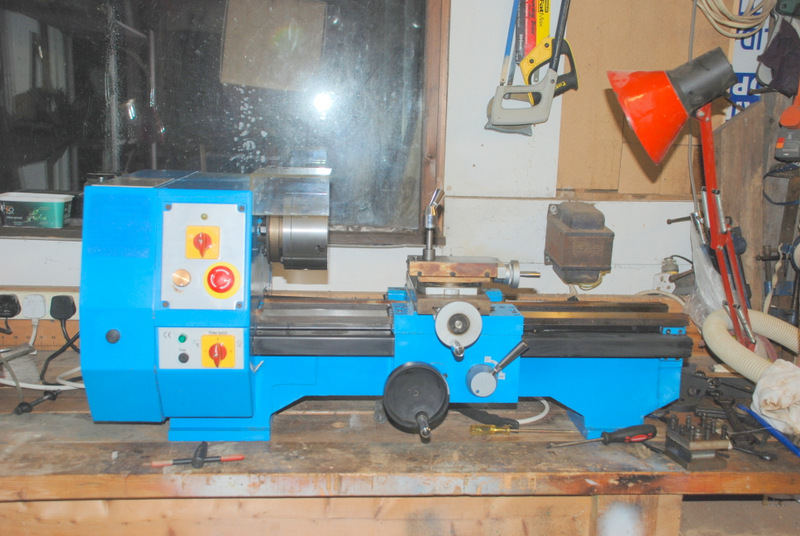

So I went along to our favourite store..Axminster....and had a look at the Sieg SC6B....which was about the size I wanted!

But for nearly £1300 quid for something made in China...I thought it was a bit much...but nicely finished none the less!

So I resisted...went home and trawled FleaBay for something similar. Imagine my amazement when I found this!

An unbranded one but with a Buy-It-Now for only £180!!

Ok...it looked rusty...but I just hit the button! Then the fun started!

First...I never even thought it would weigh bleedin' 145 Kg which is 235 LBS in old money!!!!!

Secondly it was in West London!

Now those of you who have had the pleasure of meeting my buddy and fellow crazy Douglas (aka condeesteso) will know he is one of the most generous of chaps...a true gentleman and engineer...and also enjoys a challenge!

When I mentioned my predicament...he immediately offered the use of his trailer...great bit of kit...and his time for the day so off we trekked up the M25.

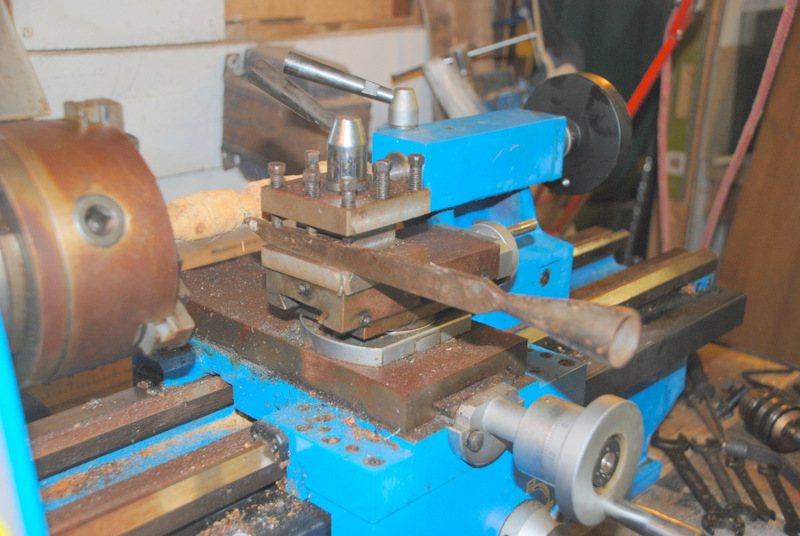

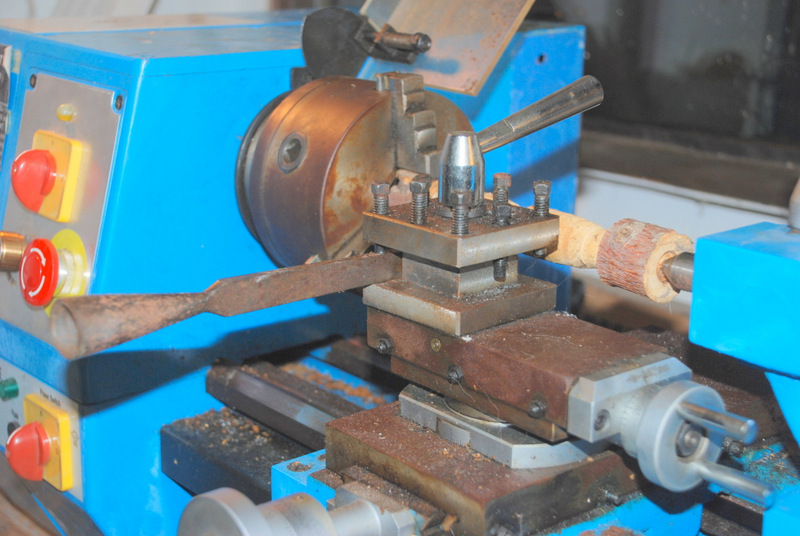

It turned out that it was housed in a lean-to greenhouse...around the back of a house and it was in much better nick than it first appeared! The "rust" was in fact the wax...impregnated with fine metal dust from one of the two attempts at use by the previous owner...

Man-handling 235 lbs of metal onto the back of a trailer is a laugh but not half as much fun as trying to get it on a bench with Douglas...my wife and an invalid with a rope! But they managed it! As Douglas says...good job H&S were not around and the beam to my workshop roof can hold that much weight...a fact that I'm rather glad of!

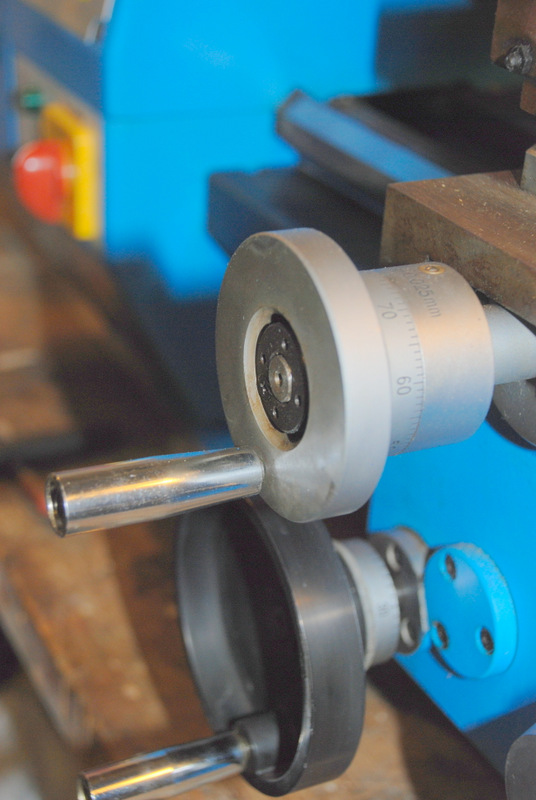

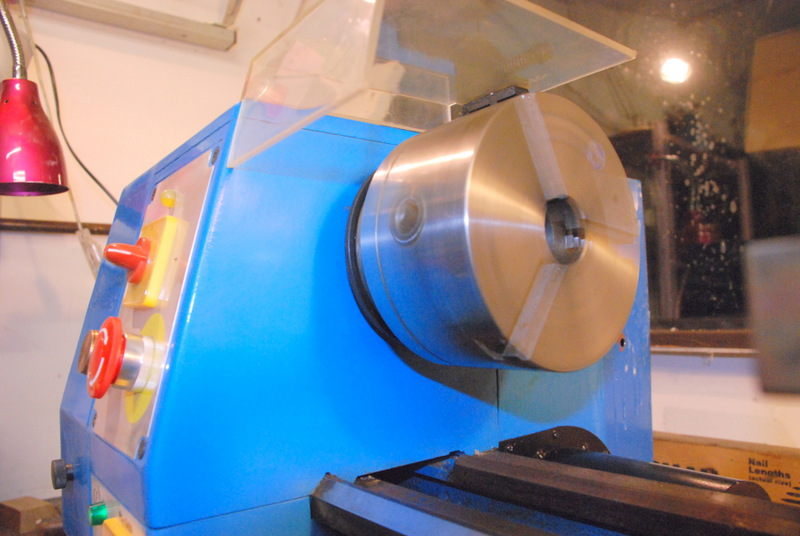

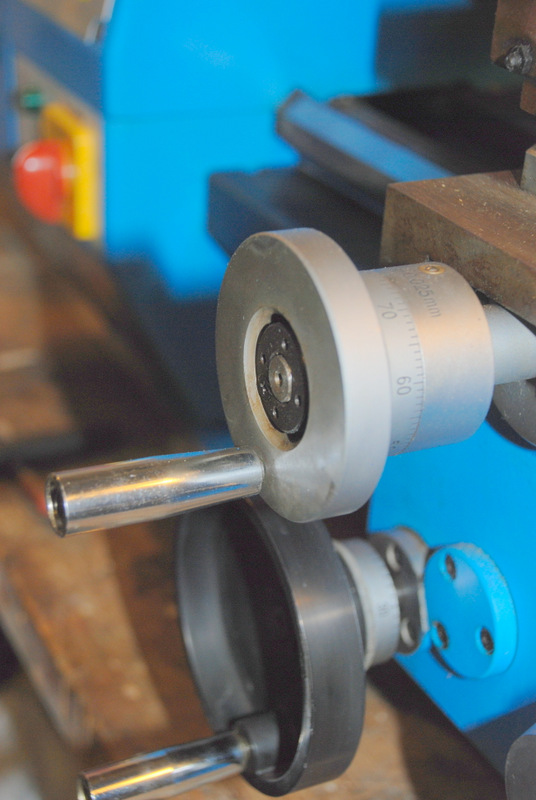

Once I cleaned the wax off...and took some mild surface rust dusting off the cross-slide...it looked fantastic....

Just got a bit more wax to remove...it's everywhere (thankfully!)....

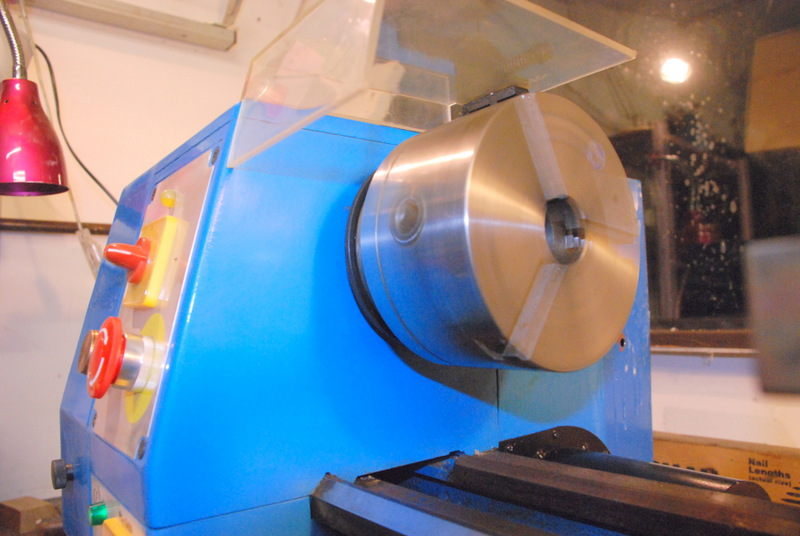

I have to say these things are really well made in the Sieg factory...one of the "higher finish" ones methinks...

The infinitely variable speed control is really smooth...

Only thing is...all the labels have bleached invisible by the light in the greenhouse so I will have to make some more!

But for £180...this has to be my bargain of the year...can't wait to play with it!

So a HUGE thanks to Douglas...if you didn't already have an ML7 I would turn up some work for you! I will have to think of something else to pay you back for this long but happy day!

Cheers mate!

Jim

So I went along to our favourite store..Axminster....and had a look at the Sieg SC6B....which was about the size I wanted!

But for nearly £1300 quid for something made in China...I thought it was a bit much...but nicely finished none the less!

So I resisted...went home and trawled FleaBay for something similar. Imagine my amazement when I found this!

An unbranded one but with a Buy-It-Now for only £180!!

Ok...it looked rusty...but I just hit the button! Then the fun started!

First...I never even thought it would weigh bleedin' 145 Kg which is 235 LBS in old money!!!!!

Secondly it was in West London!

Now those of you who have had the pleasure of meeting my buddy and fellow crazy Douglas (aka condeesteso) will know he is one of the most generous of chaps...a true gentleman and engineer...and also enjoys a challenge!

When I mentioned my predicament...he immediately offered the use of his trailer...great bit of kit...and his time for the day so off we trekked up the M25.

It turned out that it was housed in a lean-to greenhouse...around the back of a house and it was in much better nick than it first appeared! The "rust" was in fact the wax...impregnated with fine metal dust from one of the two attempts at use by the previous owner...

Man-handling 235 lbs of metal onto the back of a trailer is a laugh but not half as much fun as trying to get it on a bench with Douglas...my wife and an invalid with a rope! But they managed it! As Douglas says...good job H&S were not around and the beam to my workshop roof can hold that much weight...a fact that I'm rather glad of!

Once I cleaned the wax off...and took some mild surface rust dusting off the cross-slide...it looked fantastic....

Just got a bit more wax to remove...it's everywhere (thankfully!)....

I have to say these things are really well made in the Sieg factory...one of the "higher finish" ones methinks...

The infinitely variable speed control is really smooth...

Only thing is...all the labels have bleached invisible by the light in the greenhouse so I will have to make some more!

But for £180...this has to be my bargain of the year...can't wait to play with it!

So a HUGE thanks to Douglas...if you didn't already have an ML7 I would turn up some work for you! I will have to think of something else to pay you back for this long but happy day!

Cheers mate!

Jim