jimi43

Established Member

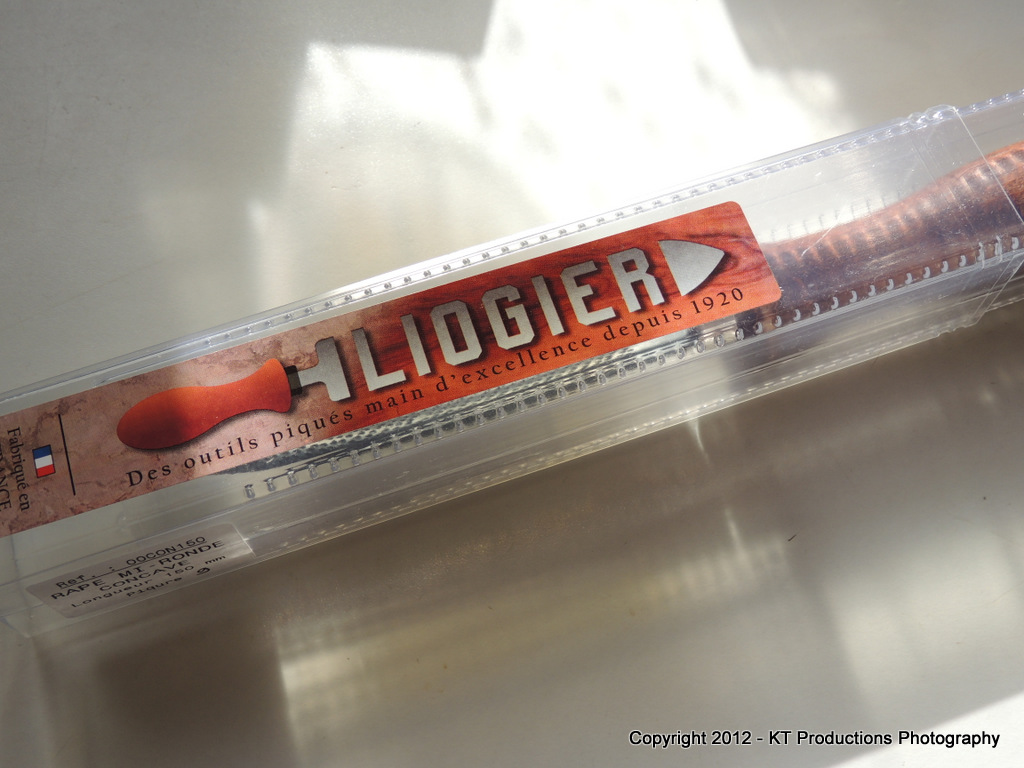

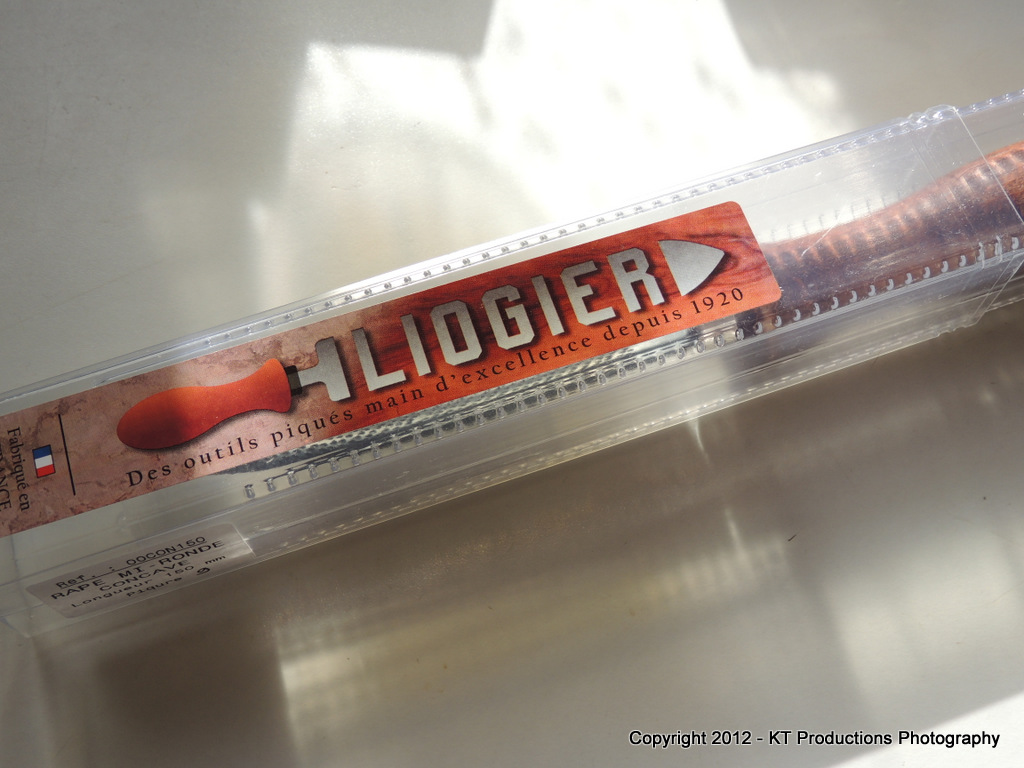

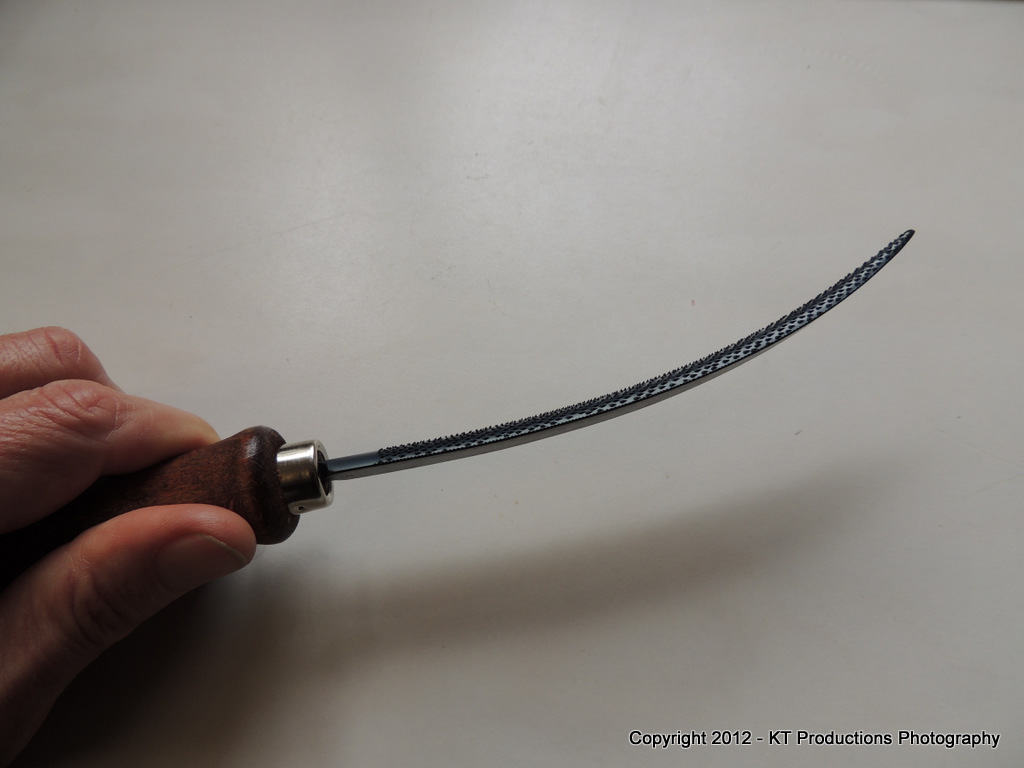

Today in the post...a little box from across La Manche...containing a very special little tool....

Those of you following the UK Workshop Infill Project and Scottish Infill Smoother Restoration threads will know that this is the vital bit of kit I have been waiting for to finish these projects with ease.

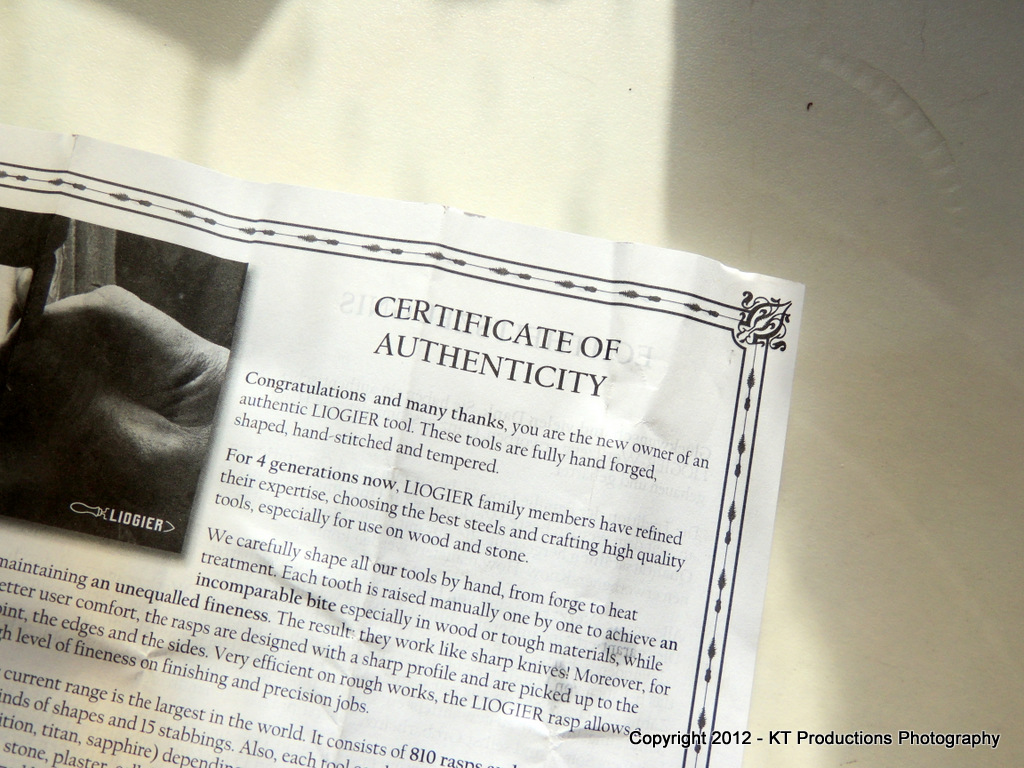

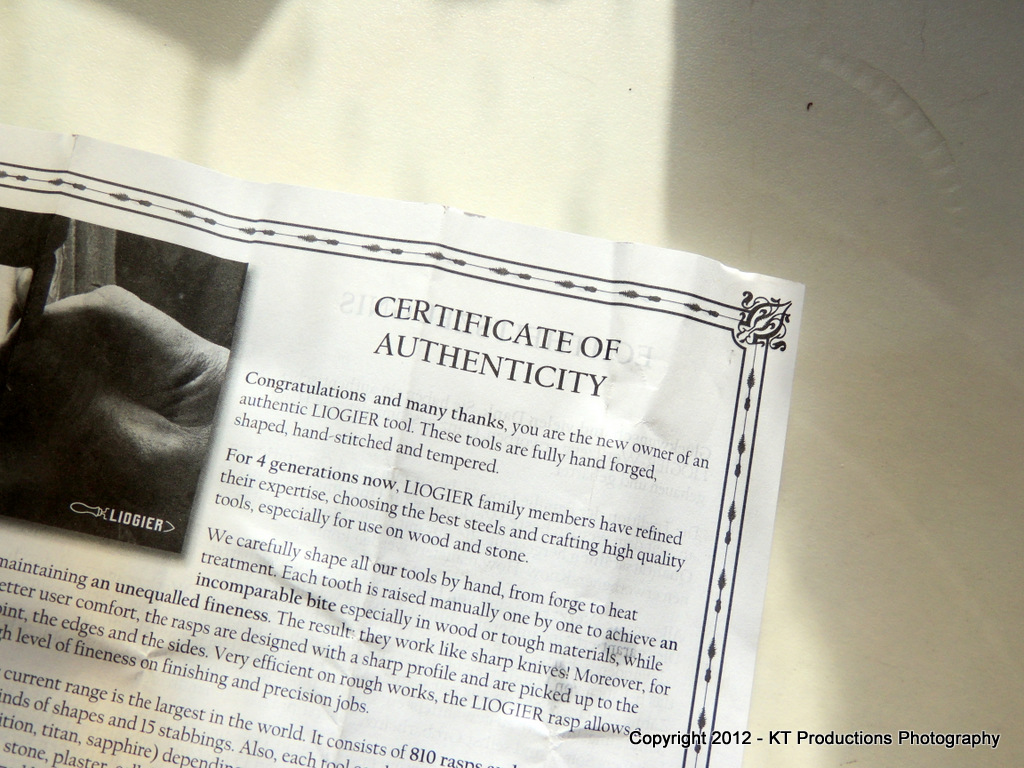

Inside the box...a Certificate of Authenticity...

...which gives a rather interesting history of the company and the work that goes into one of these little beauties.

For those of you who have not seen the video CLICK HERE - it's worth it!

The handle maker version of their range has been created as a direct result of customer demand and feedback from many fine experts...such as our dear friend Klaus...in order to produce a purpose-made tool for that specific use.

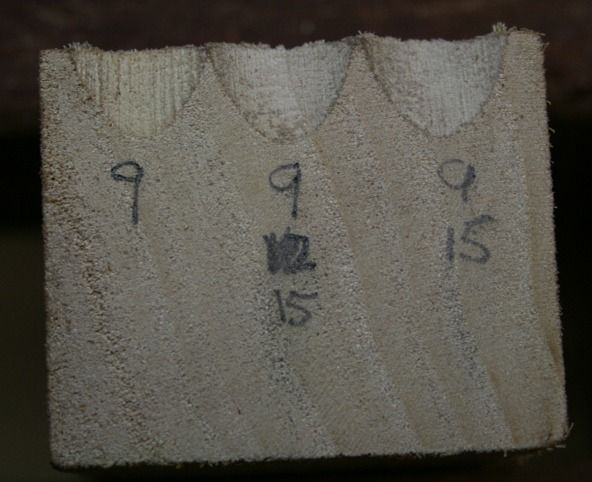

The rear of the tool is "safe"..that is to say it has no teeth. This enables safe working on one side of the inner handle without the risk of accidental damage to the other. This is a key benefit, as these things are sharp and cut in the blink of an eye.

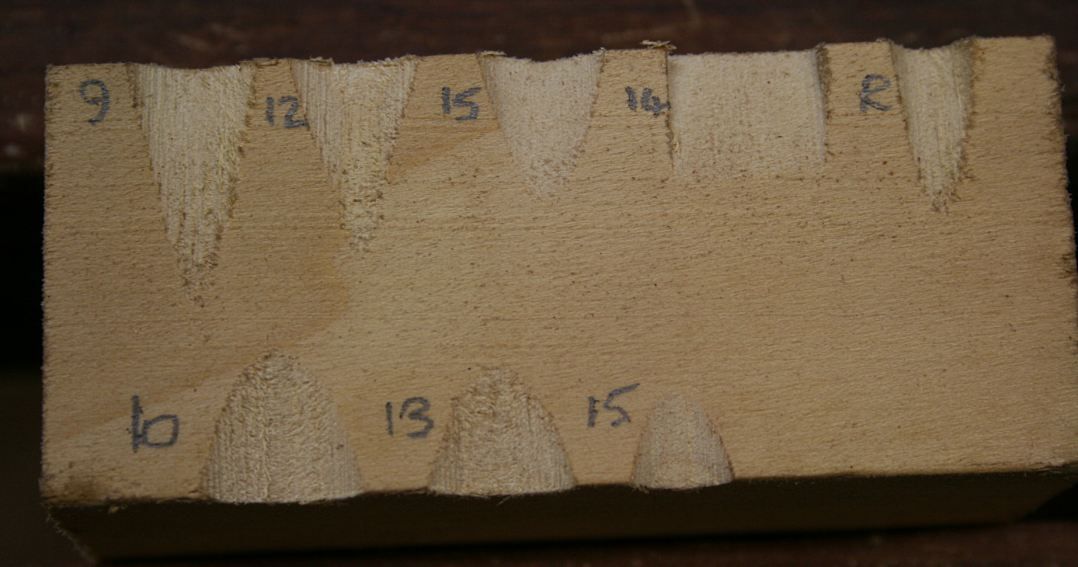

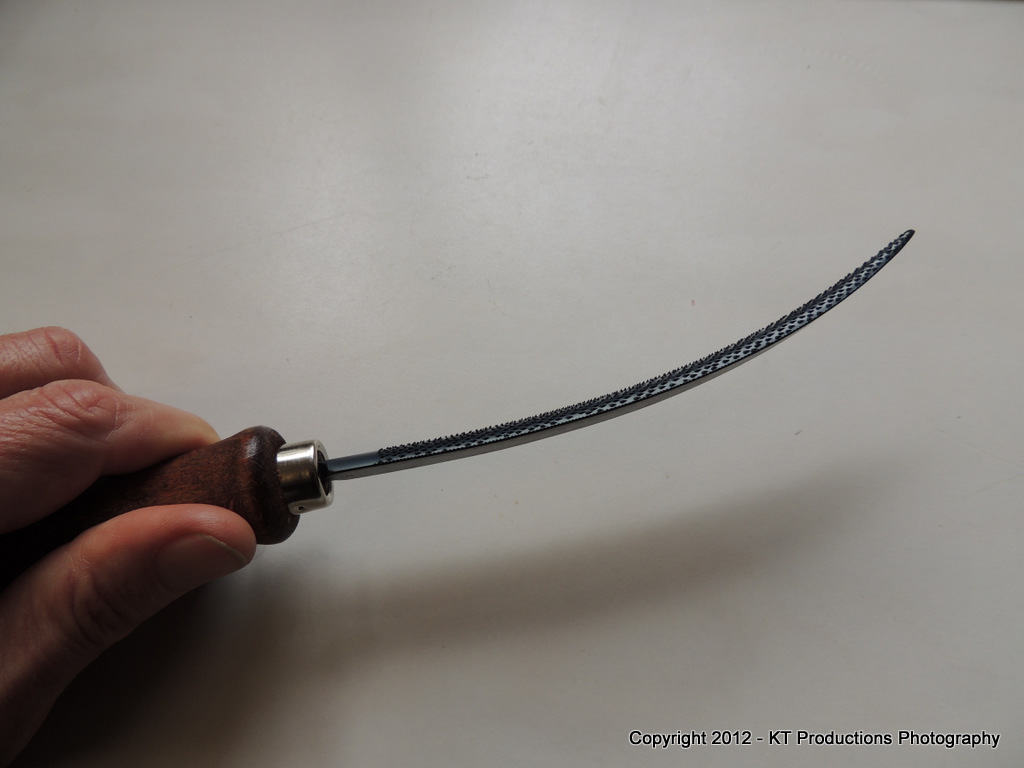

In the same way...the curvature has been optimised for the job....

...a sleek tapered curvature enabling ease of access to tricky parts.

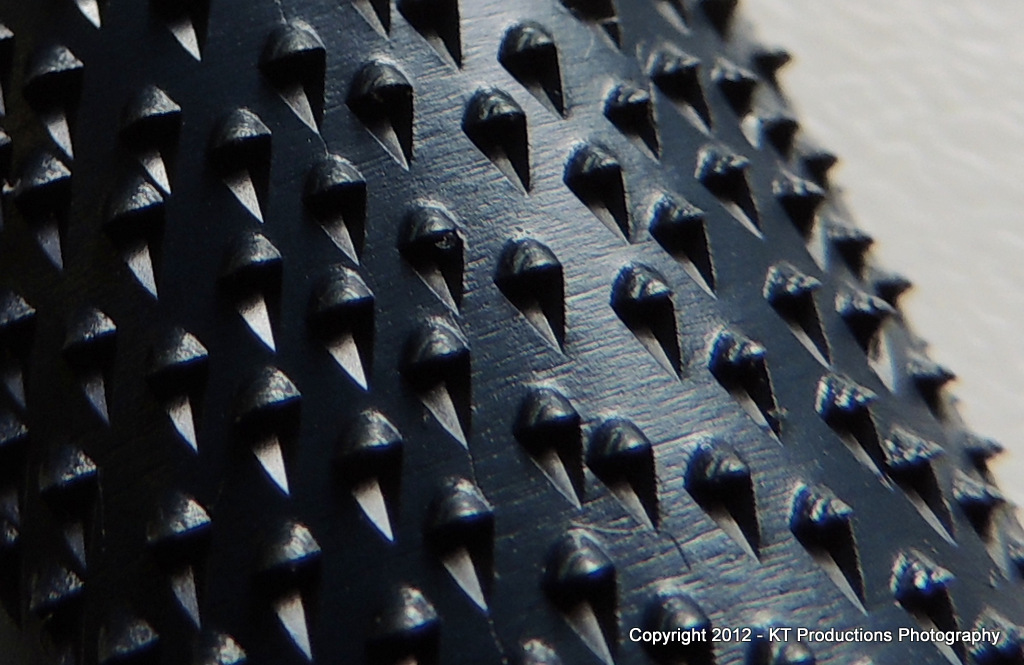

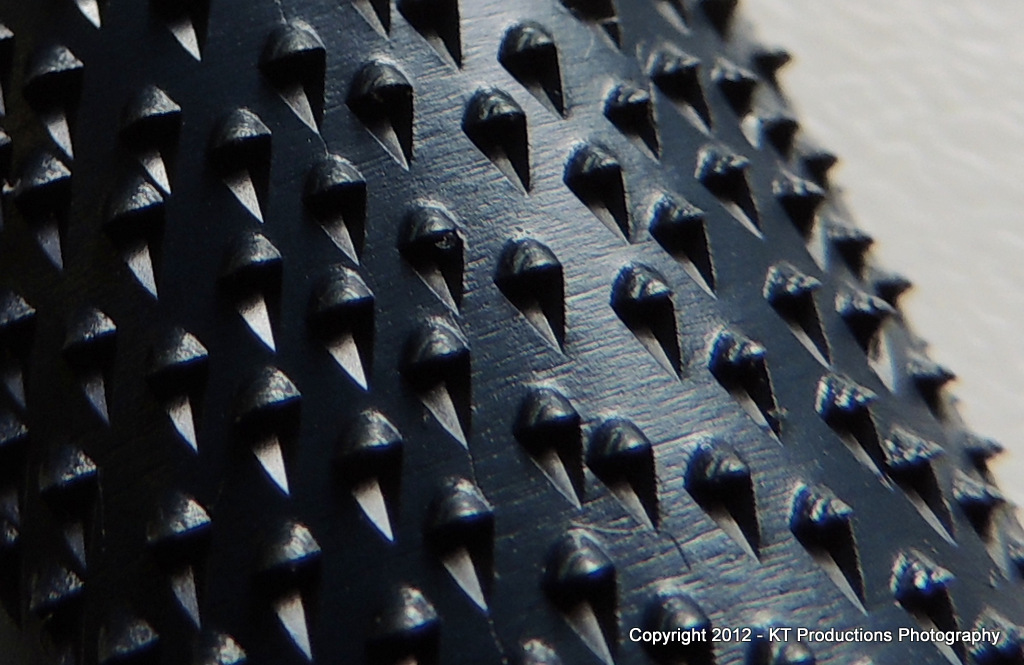

It's difficult to see that this is a random stitch...such is the skill of the craftsman....

...but close up one can see clearly that this is hand-stitched...

I will be posting some "action" shots on both of the other threads...

I think I will refrain from my normal trick of fondling all my new tools for a while...I think that might be a mistake! :shock:

But I will be testing it out tomorrow...so look out for the results soon.

Model: Handlemaker Piqure 9 Longueur 150mm Saphir

Jim

Those of you following the UK Workshop Infill Project and Scottish Infill Smoother Restoration threads will know that this is the vital bit of kit I have been waiting for to finish these projects with ease.

Inside the box...a Certificate of Authenticity...

...which gives a rather interesting history of the company and the work that goes into one of these little beauties.

For those of you who have not seen the video CLICK HERE - it's worth it!

The handle maker version of their range has been created as a direct result of customer demand and feedback from many fine experts...such as our dear friend Klaus...in order to produce a purpose-made tool for that specific use.

The rear of the tool is "safe"..that is to say it has no teeth. This enables safe working on one side of the inner handle without the risk of accidental damage to the other. This is a key benefit, as these things are sharp and cut in the blink of an eye.

In the same way...the curvature has been optimised for the job....

...a sleek tapered curvature enabling ease of access to tricky parts.

It's difficult to see that this is a random stitch...such is the skill of the craftsman....

...but close up one can see clearly that this is hand-stitched...

I will be posting some "action" shots on both of the other threads...

I think I will refrain from my normal trick of fondling all my new tools for a while...I think that might be a mistake! :shock:

But I will be testing it out tomorrow...so look out for the results soon.

Model: Handlemaker Piqure 9 Longueur 150mm Saphir

Jim