You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Life after death for my back-saw

- Thread starter baldpate

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Well, how wrong can you be!baldpate":1l5o0mhs said:Having made the inital notches in the blade (2 strokes in each notch with the 5" Extra slim) and having removed the paper guide, I find I have one or two 'dips', where I filed deeper than intended - perhaps caused by an extra stoke or two, where I thought I had not made a deep enough (or accurate enough) impression. I also recall one notch where the file 'jumped' to the adjacent one just cut, so perhaps that was the cause. The paper guide was invaluable (could not have managed without it) but it did tend to obscure imperfect positioning in the initial cuts - the torn paper makes the cuts to the metal seem more regular than in fact they are once the paper is removed.

...

Despite a couple of imperfections I intend to press on (rather than starting again) but using the needle file, hoping I can file out the imperfections as I go on.

I think I've at last got the teeth cut and ready to set - but jeez :roll: , a fellow could loose the will to live!! I didn't count, but I must have spent a good 5 hours peering through a jeweller loup and filing away those flats! I had to re-flatten twice (not completely, I mean - just enough to get those shiny flat tops back on all the teeth) because the tooth height was all over the place on my first try, and still not good enough on the second.

The price I seem to have paid for a flat tooth profile is a fair bit of variation in gullet width & depth (i.e. it might average 15 tpi, but many teeth will be a bit more or a bit less than 1/5th " apart). I'm assuming this results from the initial inaccuracies in registering the profile. I hope this won't matter too much, provided the teeth are mostly the same height (one ot two low ones, though) - is that right?

Also, I don't think I made a very good job of initial flattening (i.e before any filing). I used the only flat file I own, which came as part of a cheap set from Lidl, with handle attached (making it a bit awkward to run flat along the blade). For the two intermediate re-flattenings I hit on the idea of using one of those cheap 6" diamond sharpening 'stones', which seemed to work very well : they're wide enough (2") that you can use a block of wood to keep the diamond stone flat and square to the blade as you run it backwards and forwards.

What tool do other people use for flattening - I assume a file, but how long and what cut is best?

Regards

Chris

EDIT: I originally wrote 25tpi & 1/25" spacing - I meant 15 tpi & 1/15" of course (now corrected)!

xy mosian

Established Member

Random tooth spacing? I recon it will still cut well, after all rasp users think random, hand cut, teeth are better. Ok! I know it's different but seriously if it works use it.

xy

xy

The first saw I sharpened was something like a 15 TPI Gents saw (brave of me). It went from very blunt evenly shaped teeth to sharp but varying up, down, low mountain, high mountain. It cut pretty good!!

Hi,

random gullet width doesn't hurt at sawing at all. It is just the look. The saw will cut proper!

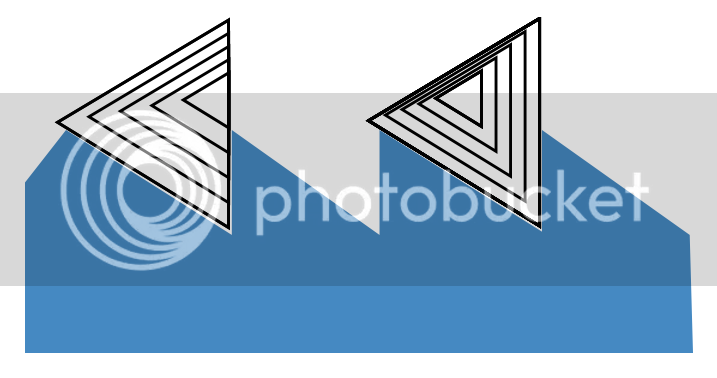

This is a picture of my first toothing:

After that saw I never tried to tooth with a paper pattern again.

Peter, I file the gullets on rip saws in 3 runs:

two strokes with the pattern attached

2-? strokes until the flats are gone nearly complete.

setting

light jointing with a 150mm cut 3 file

2-? strokes until the flats are gone

I have to worry about even gullets because the customer won't like a saw like above.

BTW I just retoothed tha special saw after 5 years of use.

Cheers

Pedder

random gullet width doesn't hurt at sawing at all. It is just the look. The saw will cut proper!

This is a picture of my first toothing:

After that saw I never tried to tooth with a paper pattern again.

Peter, I file the gullets on rip saws in 3 runs:

two strokes with the pattern attached

2-? strokes until the flats are gone nearly complete.

setting

light jointing with a 150mm cut 3 file

2-? strokes until the flats are gone

I have to worry about even gullets because the customer won't like a saw like above.

BTW I just retoothed tha special saw after 5 years of use.

Cheers

Pedder

bugbear

Established Member

Pete Maddex":1rphmftz said:Hi, Pedder

O/k I see, do you file each tooth to the full depth?

The one I did was a small rip saw for dovetails.

Pete

I think I understand;

I think Pedder is filing as per the left hand sequence; once the intial stroke is made, the final position of the tooth is fully determined.

Pete (OTOH) is proceeding as per the right hand sequence, growing the gullet both left and right. He thus has some choices right until full gullet depth is reached.

BugBear

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£238.91

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

Me again!

just to thank you again for all your help and to post a picture of the final result - here it is

It's a long way from the high standards I've seen elsewhere in the forum, but it's OK for a first attempt I think - cuts straight & fast, and feels comfortable. I made the handle from an offcut of 1" IKEA engineered oak shelving given me by my daughter - not an ideal material, I know, but I didn't have any other hardwood thick enough, and I wasn't about to shell out for something that might have ended up as a dud! You can probably see how uneven the teeth are, but (apart from some low ones) the teeth are mostly at the same height : it seems to cut OK.

Interestingly, I found making the new handle the easier part of the job, although I expected it to be the more difficult (less problematic, not less time). Shaping the new teeth definitely gave me more grief.

Once I've had time to forget the trauma of this first childbirth, I may even be tempted to have a go at another 'old lady' currently languishing in the discard pile .

.

just to thank you again for all your help and to post a picture of the final result - here it is

It's a long way from the high standards I've seen elsewhere in the forum, but it's OK for a first attempt I think - cuts straight & fast, and feels comfortable. I made the handle from an offcut of 1" IKEA engineered oak shelving given me by my daughter - not an ideal material, I know, but I didn't have any other hardwood thick enough, and I wasn't about to shell out for something that might have ended up as a dud! You can probably see how uneven the teeth are, but (apart from some low ones) the teeth are mostly at the same height : it seems to cut OK.

Interestingly, I found making the new handle the easier part of the job, although I expected it to be the more difficult (less problematic, not less time). Shaping the new teeth definitely gave me more grief.

Once I've had time to forget the trauma of this first childbirth, I may even be tempted to have a go at another 'old lady' currently languishing in the discard pile

Attachments

bugbear

Established Member

baldpate":15dj93lb said:Me again!

just to thank you again for all your help and to post a picture of the final result - here it is

It's a long way from the high standards I've seen elsewhere in the forum, but it's OK for a first attempt I think - cuts straight & fast, and feels comfortable. I made the handle from an offcut of 1" IKEA engineered oak shelving given me by my daughter - not an ideal material, I know, but I didn't have any other hardwood thick enough, and I wasn't about to shell out for something that might have ended up as a dud! You can probably see how uneven the teeth are, but (apart from some low ones) the teeth are mostly at the same height : it seems to cut OK.

Interestingly, I found making the new handle the easier part of the job, although I expected it to be the more difficult (less problematic, not less time). Shaping the new teeth definitely gave me more grief.

Once I've had time to forget the trauma of this first childbirth, I may even be tempted to have a go at another 'old lady' currently languishing in the discard pile.

Wow.

You've successfully created fine teeth that cut fast and straight. I note you used a jeweller loupe to help - I'd recommend either something like a "proper" binocular magnifier if you're feeling flush, or a pair of high power supermarket/chemist reading glasses (+3 or +4 dioptre) if you're not.

You've made a good looking handle - in particular you've avoided the classic mistake of merely rounding the arris of a sawn profile, as opposed to making a comfortably round handle.

That's one hell of a good job.

=D> =D> =D> =D> =D> =D> =D> =D> =D> =D>

BugBear

Hi baldpate,

that is a beatiful handle. The most critical parts in saw making are the slots in the handle. The rest is filing and sanding.

Your teeth look much better than my first set, and both, yours and mine cut well. So I've to warn you: Saw making is highly addictive!

Cheers

Pedder

that is a beatiful handle. The most critical parts in saw making are the slots in the handle. The rest is filing and sanding.

Your teeth look much better than my first set, and both, yours and mine cut well. So I've to warn you: Saw making is highly addictive!

Cheers

Pedder

I must own to 'cheating' a bit when rounding the grip of the handle. I removed the bulk of the material on the router table with a finely set 3/8" round-over bit, which got me close to the required profile; fiing and sanding then took out the machining marks, and allowed me to concentrate on getting the final shape and finish. I wasn't confident I would get an even shape if I used hand-tools only.

jimi43

Established Member

A superb start to what I imagine will be an addiction sometime soon!

I too like the shape of the handle and there's nothing wrong with profiling with a router...you are only removing the excess bulk wood anyway...it's the hand finishing that turn a potentially ordinary handle into something special...and more importantly...uniquely yours!

I have been following this thread with interest, partly deciding whether to pluck up the courage to start saw making myself....and I have come to the conclusion I will be leaving it to the experts and people with far more patience than me!

Well done mate! Well done indeed! =D> =D> =D>

Jimi

I too like the shape of the handle and there's nothing wrong with profiling with a router...you are only removing the excess bulk wood anyway...it's the hand finishing that turn a potentially ordinary handle into something special...and more importantly...uniquely yours!

I have been following this thread with interest, partly deciding whether to pluck up the courage to start saw making myself....and I have come to the conclusion I will be leaving it to the experts and people with far more patience than me!

Well done mate! Well done indeed! =D> =D> =D>

Jimi

swagman

Established Member

baldpate":6uau2p0c said:Well, how wrong can you be!baldpate":6uau2p0c said:Having made the inital notches in the blade (2 strokes in each notch with the 5" Extra slim) and having removed the paper guide, I find I have one or two 'dips', where I filed deeper than intended - perhaps caused by an extra stoke or two, where I thought I had not made a deep enough (or accurate enough) impression. I also recall one notch where the file 'jumped' to the adjacent one just cut, so perhaps that was the cause. The paper guide was invaluable (could not have managed without it) but it did tend to obscure imperfect positioning in the initial cuts - the torn paper makes the cuts to the metal seem more regular than in fact they are once the paper is removed.

...

Despite a couple of imperfections I intend to press on (rather than starting again) but using the needle file, hoping I can file out the imperfections as I go on.

I think I've at last got the teeth cut and ready to set - but jeez :roll: , a fellow could loose the will to live!! I didn't count, but I must have spent a good 5 hours peering through a jeweller loup and filing away those flats! I had to re-flatten twice (not completely, I mean - just enough to get those shiny flat tops back on all the teeth) because the tooth height was all over the place on my first try, and still not good enough on the second.

The price I seem to have paid for a flat tooth profile is a fair bit of variation in gullet width & depth (i.e. it might average 15 tpi, but many teeth will be a bit more or a bit less than 1/5th " apart). I'm assuming this results from the initial inaccuracies in registering the profile. I hope this won't matter too much, provided the teeth are mostly the same height (one ot two low ones, though) - is that right?

Also, I don't think I made a very good job of initial flattening (i.e before any filing). I used the only flat file I own, which came as part of a cheap set from Lidl, with handle attached (making it a bit awkward to run flat along the blade). For the two intermediate re-flattenings I hit on the idea of using one of those cheap 6" diamond sharpening 'stones', which seemed to work very well : they're wide enough (2") that you can use a block of wood to keep the diamond stone flat and square to the blade as you run it backwards and forwards.

What tool do other people use for flattening - I assume a file, but how long and what cut is best?

Regards

Chris

EDIT: I originally wrote 25tpi & 1/25" spacing - I meant 15 tpi & 1/15" of course (now corrected)!

Hi Chris. Can I suggest a couple of things that will improve your saw sharpening. Get yourself a good quality 12 inch, 2nd cut Mill File for jointing the tooth line. It will make a big difference as good jointing is a very important part of saw sharpening. Also get yourself some Blue Steel Marking Dye. Use an old toothbrush to apply the blue dye across the teeth prior to any file work. The blue dye makes it much easier to see what is being filed away. Start your saw tooth shaping stage with the file set at 0 degrees. (vertical line entry). Complete the shaping in 2-3 passes, keeping the flat on all of the teeth the same width after each pass. Dont forget, re apply the blue dye before each filing pass. When you are left with just a tiny flat spot on each tooth, you then need to stop and then give the teeth a couple of (light passes) with your jointing file. Re-apply your blue dye. Now you are ready for the next stage to shaping the teeth. Rotate your file to a new angle that will add negative rake to the front profile on each tooth. Re-apply the blue dye and file the teeth to a tiny flat. That completes the shaping stage.

Hope this helps.

Regards; Stewie.

Similar threads

- Replies

- 1

- Views

- 419