Lons

Established Member

Hi Rod

Are you sure it's a K5 machine you have?

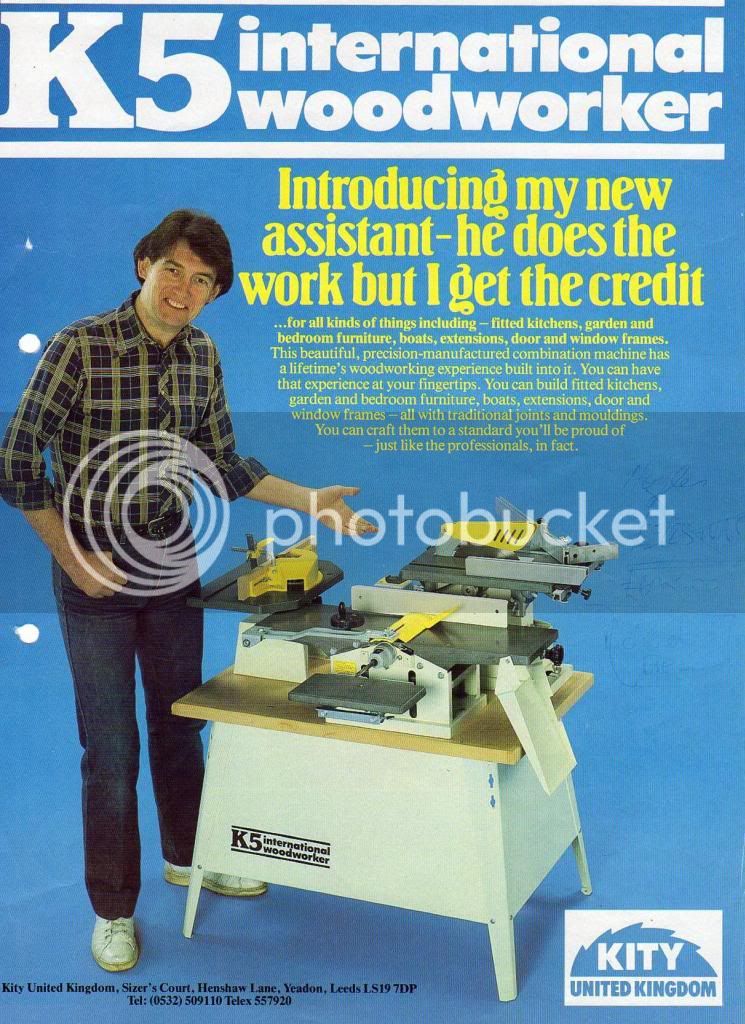

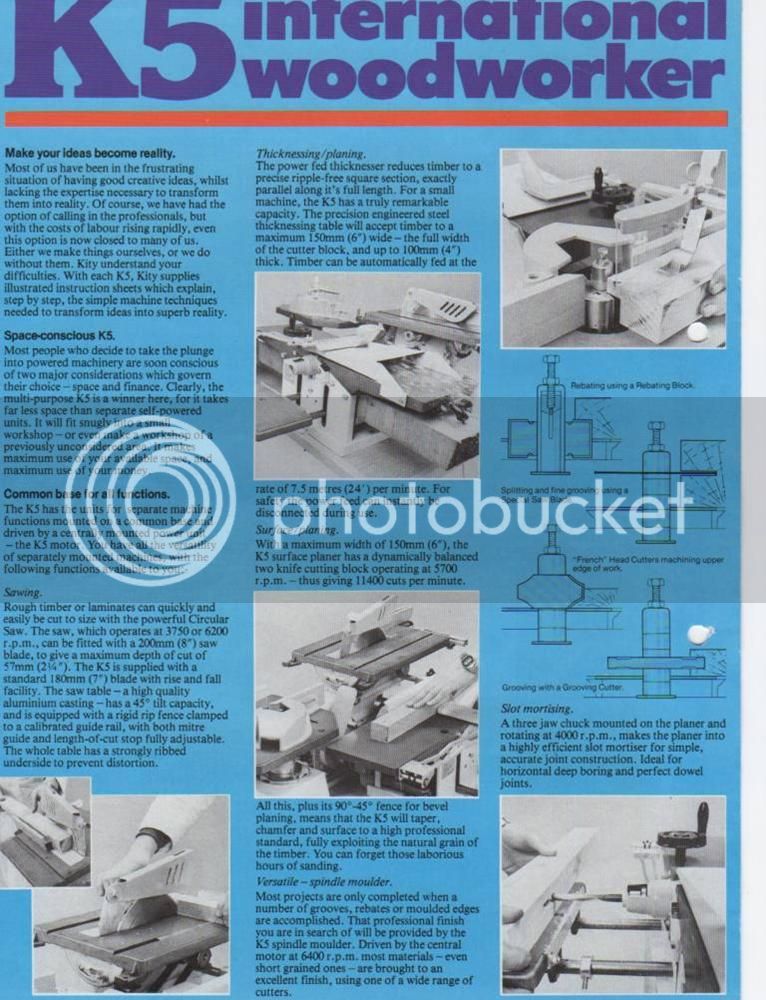

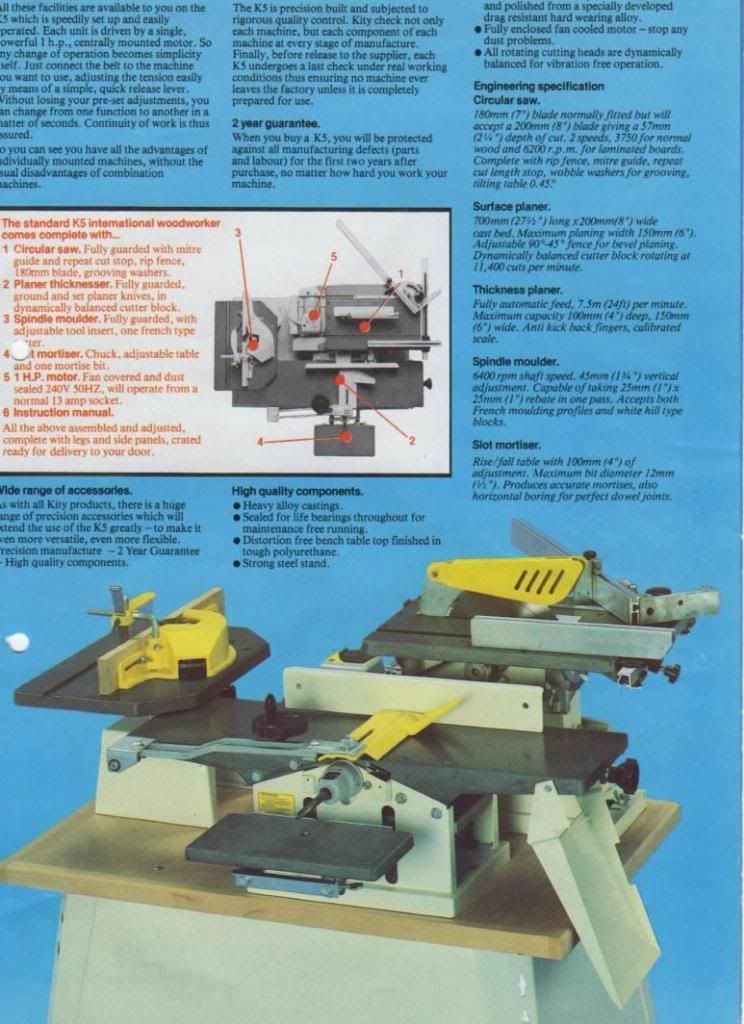

The K5 concept was a combination of small seperate machines mounted on a table and operated by one central motor and as far as I know only one common belt. My 1980s machine and the later (green) Bestcombi are certainly that and I'm almost 100% sure the early ones were as well.

It sounds as if you might have either an unusual setup or more likely a version of the larger machine of which there were 4 or 5 versions depending on which machines were supplied. It was a similar principle but could be converted for each machine to operated individually with it's own moter at a later date. In fact Kity advertised this as the only machine on the market with this facility. They later consolodated the range with the K704 followed by the CK26 and direct drive models.

I have some old brochures and leaflets packed away including a general brochure from around 1980 / 81 ish so will have a look when i get a chance.

I'm puzzled and curious. If you post a couple of pics I can probably tell you.

cheers

Bob

Are you sure it's a K5 machine you have?

The K5 concept was a combination of small seperate machines mounted on a table and operated by one central motor and as far as I know only one common belt. My 1980s machine and the later (green) Bestcombi are certainly that and I'm almost 100% sure the early ones were as well.

It sounds as if you might have either an unusual setup or more likely a version of the larger machine of which there were 4 or 5 versions depending on which machines were supplied. It was a similar principle but could be converted for each machine to operated individually with it's own moter at a later date. In fact Kity advertised this as the only machine on the market with this facility. They later consolodated the range with the K704 followed by the CK26 and direct drive models.

I have some old brochures and leaflets packed away including a general brochure from around 1980 / 81 ish so will have a look when i get a chance.

I'm puzzled and curious. If you post a couple of pics I can probably tell you.

cheers

Bob