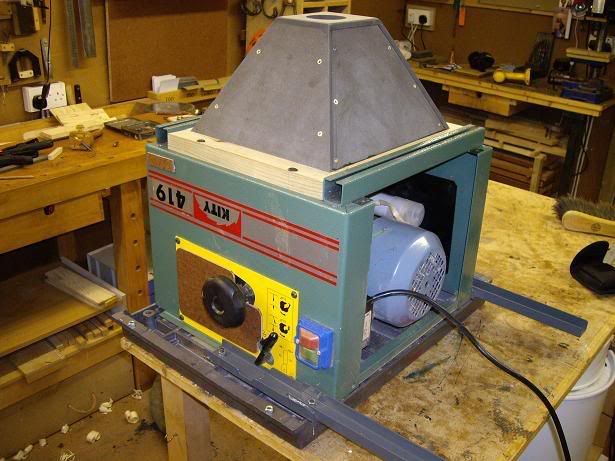

well I fired up the kity at the weekend after too many moons away.

cut some kickboards for my kitchen and a door for my youngest lads room airing cupboard.

I was truely shocked at just how bad the dust extraction was on my 419 with just the shop vac connected to the blade "scoop" (on the back).

so my next project I`m thinking of is a possibe conical dust hopper to fit under the mobile table its on.

What is the general consensus? show I modify the existing mobilebase/kity stand that is on at the moment, or build a dedicated table saw station?

bearing in mind it needs to be mobile...... (small workshop :-( )

for the hopper idea I was thinking about a conical design sitting under the kity (top of the kity base that the saw is bolted to, cut or removed) sealed with good positive air flow down through the hopper into the dust extractor.

have people experimented with this type of system?

Steve

cut some kickboards for my kitchen and a door for my youngest lads room airing cupboard.

I was truely shocked at just how bad the dust extraction was on my 419 with just the shop vac connected to the blade "scoop" (on the back).

so my next project I`m thinking of is a possibe conical dust hopper to fit under the mobile table its on.

What is the general consensus? show I modify the existing mobilebase/kity stand that is on at the moment, or build a dedicated table saw station?

bearing in mind it needs to be mobile...... (small workshop :-( )

for the hopper idea I was thinking about a conical design sitting under the kity (top of the kity base that the saw is bolted to, cut or removed) sealed with good positive air flow down through the hopper into the dust extractor.

have people experimented with this type of system?

Steve