devonwoody

Established Member

--------------------------------------------------------------------------------

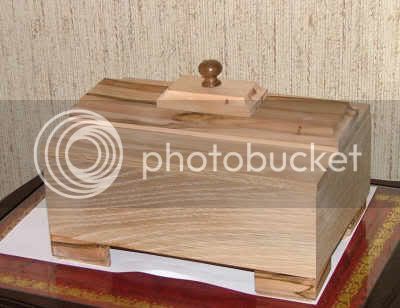

Started the New Year (Sunday) and making a jewellery box and I am hoping this time it doesn't have to become another screw box for my workshop.

The timber being used is English Oak offcuts purchased from a local timber outlet and photographs attached.

This time I am going to be meticulous in preparation and also at the gluing up stage want 100% accuracy.

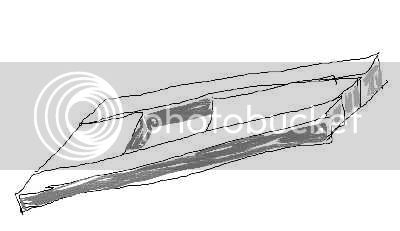

After preparing the timber around 90 minutes work with the P/T and bandsaw. The table saw was useless in effecting a resaw at 80mm height when wanting to reduce the timber from 16 mm to 12mm. However the bandsaw was in a good mood and cut the pieces without any hiccups. Went to the P/T again and cleaned upto 10mm thickness on all pieces.

Pictures show how I stacked the prepared timber overnight with a brick loaded for good measure, I didn't want any stressed boards breaking out on me the next day.

Monday:-

The timber was then put to the tablsesaw and a 3.2mm (kerf size) dado was cut at the bottom edge, 4mm deep, for the base piece to be fitted later using 4mm ply.

The mitre corners was the next job and I used the tablesaw again with its ripping blade attached, NOT A GOOD IDEA the small offcuts flew around the workshop in a very dangerous manner, also would not cut mitres cleanly as per this picture.

I decided to take the CMT blade (60T and 1.7mm kerf) off my mitre chop saw and put it on the tablesaw knowing in the past that this provides a much nicer cross cut at the table. Naturally I would not attempt to do any ripping with this type of blade, but I wanted some mitre cuts that would be good looking for a jewellery box. Pleased to say they cut well.

A rebate was then necessary for the top edge of the box which I performed on the Triton router table using a dedicated rebate cutter. This top edge is going to take a drop on lid which I think might be a first with the design I have got in mind, so as they say watch this space.

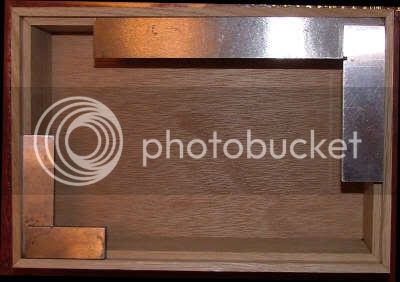

Next I did a trial setup gluing run as per these pictures.

I have knocked out a jig with sliding bars ( did think of putting some on the top edge as well but they didn't seem to be needed for this occassion) A 4mm ply base was then cut and edges cleaned up to fit the dado mentioned above. Another trial run and some adjustments needed to get the base to fit,

but then worked out OK as per final pictures showing the glue up stage in the usual Brittish gluing room during our winter time.

So that was one hours work new years day and around 4 hours yesterday and looking forward to taking the box out of the jig.

Then comes the LID!!!!!!!!!!!

Started the New Year (Sunday) and making a jewellery box and I am hoping this time it doesn't have to become another screw box for my workshop.

The timber being used is English Oak offcuts purchased from a local timber outlet and photographs attached.

This time I am going to be meticulous in preparation and also at the gluing up stage want 100% accuracy.

After preparing the timber around 90 minutes work with the P/T and bandsaw. The table saw was useless in effecting a resaw at 80mm height when wanting to reduce the timber from 16 mm to 12mm. However the bandsaw was in a good mood and cut the pieces without any hiccups. Went to the P/T again and cleaned upto 10mm thickness on all pieces.

Pictures show how I stacked the prepared timber overnight with a brick loaded for good measure, I didn't want any stressed boards breaking out on me the next day.

Monday:-

The timber was then put to the tablsesaw and a 3.2mm (kerf size) dado was cut at the bottom edge, 4mm deep, for the base piece to be fitted later using 4mm ply.

The mitre corners was the next job and I used the tablesaw again with its ripping blade attached, NOT A GOOD IDEA the small offcuts flew around the workshop in a very dangerous manner, also would not cut mitres cleanly as per this picture.

I decided to take the CMT blade (60T and 1.7mm kerf) off my mitre chop saw and put it on the tablesaw knowing in the past that this provides a much nicer cross cut at the table. Naturally I would not attempt to do any ripping with this type of blade, but I wanted some mitre cuts that would be good looking for a jewellery box. Pleased to say they cut well.

A rebate was then necessary for the top edge of the box which I performed on the Triton router table using a dedicated rebate cutter. This top edge is going to take a drop on lid which I think might be a first with the design I have got in mind, so as they say watch this space.

Next I did a trial setup gluing run as per these pictures.

I have knocked out a jig with sliding bars ( did think of putting some on the top edge as well but they didn't seem to be needed for this occassion) A 4mm ply base was then cut and edges cleaned up to fit the dado mentioned above. Another trial run and some adjustments needed to get the base to fit,

but then worked out OK as per final pictures showing the glue up stage in the usual Brittish gluing room during our winter time.

So that was one hours work new years day and around 4 hours yesterday and looking forward to taking the box out of the jig.

Then comes the LID!!!!!!!!!!!