My mothers 60th is due in mid november so have decided to go for a special present AND try to develop my skills a bit. So I decided to make a jewellery box and to try incorporating dovetail joints. So on to the photos :

Original wood which was the counter-top in my mothers post-office which I think is mahogany :

planed & thicknessed :

cut the sides, nd then shot them on the shooting board :

with the new piece of kit :

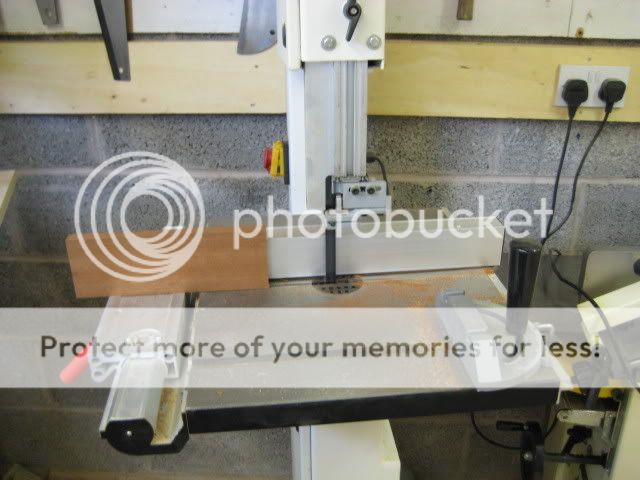

girlfriend told me that pieces looked too chunky, so ran them through the bandsaw :

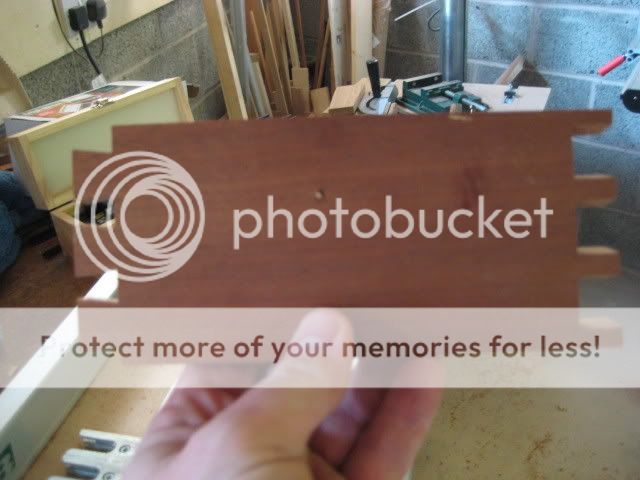

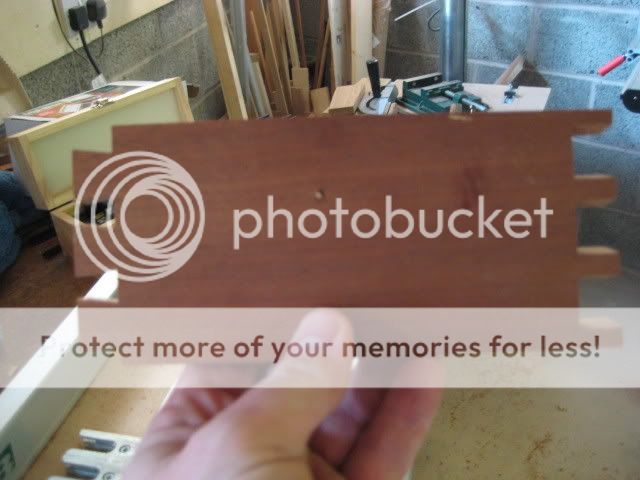

the results, slimmer sides and the side-effect (literally) of some handy veneer :

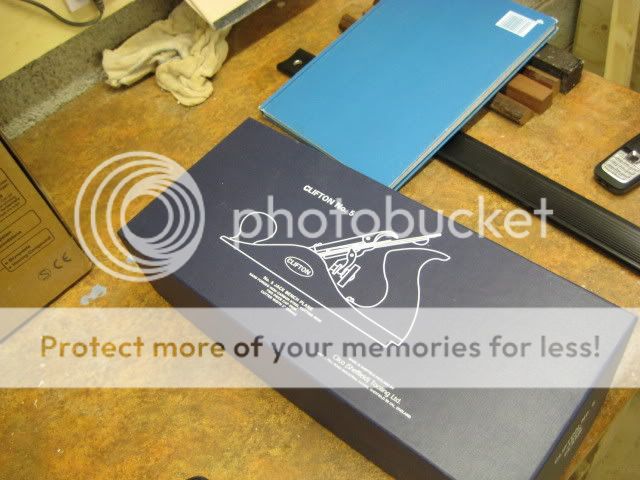

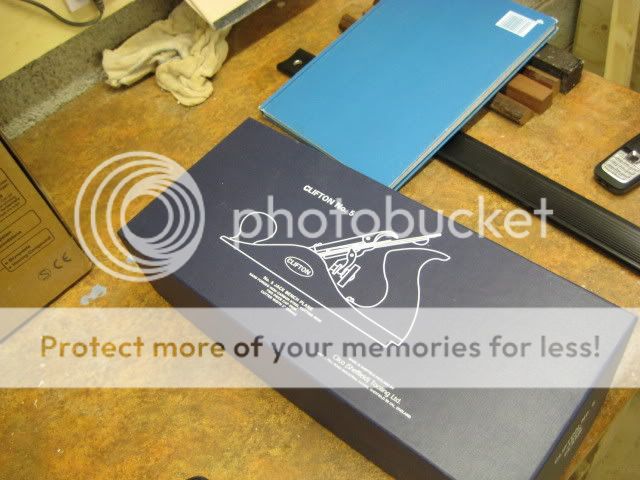

now to the scary bit, bought this :

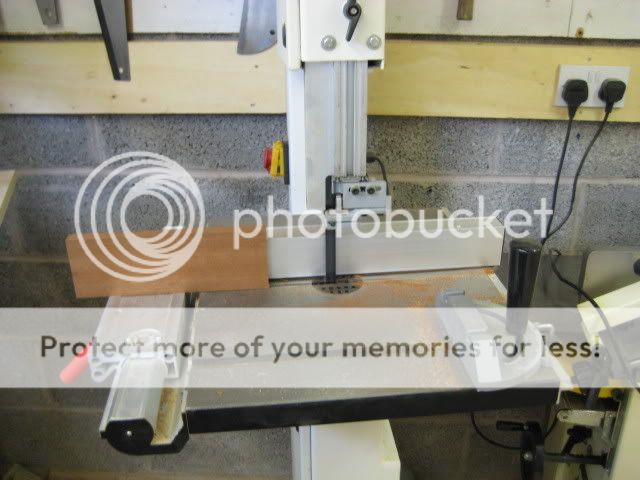

tried a test run on a scrap:

now the really scary bit :

so what happened ?? :

my god its worked!! Couldn't believe how well they came out

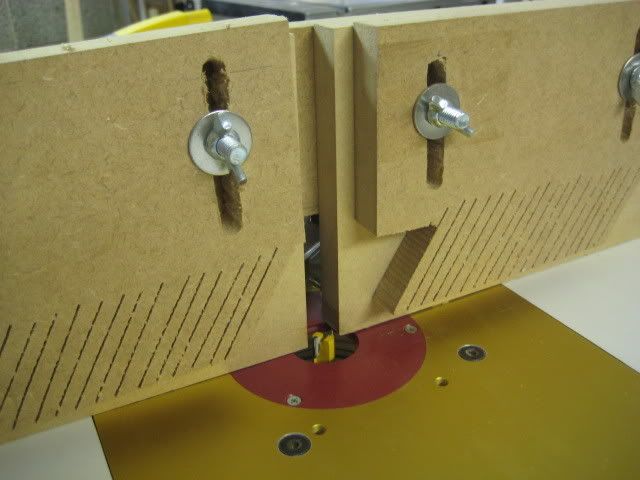

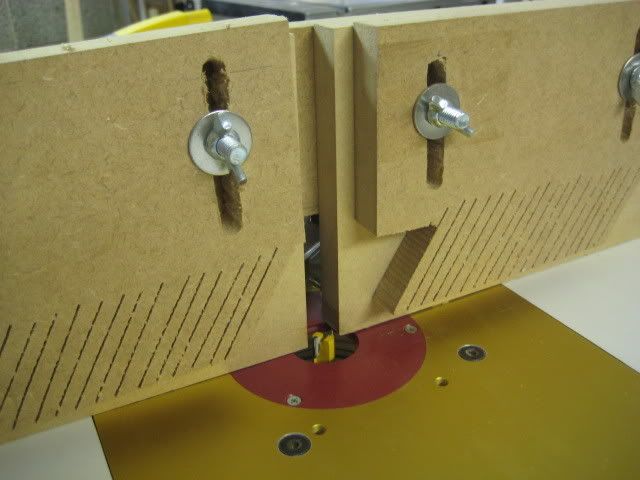

then made a rebate in the top and bottom using the router table :

had to tidy up the corners with a chisel :

then decided to glue it up, made a temporary base to keep everything square :

(mdf base, photo taken when it was sat on a piece of Chestnut, which is going to become inlay in the top

(mdf base, photo taken when it was sat on a piece of Chestnut, which is going to become inlay in the top

My plan for the base is to veneer the MDF base underneath with the pieces cut from the sides earlier, hopefully the MDF will stop anything moving as the veneer is only 3 mm thick.

Tomorrow got to start thinking about making a top, and how to hinge it (any hints / ideas or suggestions appreciated)

Original wood which was the counter-top in my mothers post-office which I think is mahogany :

planed & thicknessed :

cut the sides, nd then shot them on the shooting board :

with the new piece of kit :

girlfriend told me that pieces looked too chunky, so ran them through the bandsaw :

the results, slimmer sides and the side-effect (literally) of some handy veneer :

now to the scary bit, bought this :

tried a test run on a scrap:

now the really scary bit :

so what happened ?? :

my god its worked!! Couldn't believe how well they came out

then made a rebate in the top and bottom using the router table :

had to tidy up the corners with a chisel :

then decided to glue it up, made a temporary base to keep everything square :

My plan for the base is to veneer the MDF base underneath with the pieces cut from the sides earlier, hopefully the MDF will stop anything moving as the veneer is only 3 mm thick.

Tomorrow got to start thinking about making a top, and how to hinge it (any hints / ideas or suggestions appreciated)