Ian Dalziel

Established Member

Apologies to all for being absent, we are getting roadworks done and they keep losing our phone line hopefully be fine by monday

Japanese chisels have been around for centuries, their laminating process used in their samurai swords have been adopted into their chisels; there laminating process seems to combine great strength with a very hard long lasting edge.

The chisels I have reviewed here are the traditional butt chisels or Oire-Nomi, I purchased these from Tilgear with the brand Aka-Kashi labelled on them. Considering the prices of other oriental chisels I’ve seen; priced at £95 these are probably aimed at the introductory side of the market.

They come individually wrapped in polythene envelopes with plastic tip protectors; the handles are red ash with a heavy coat of varnish, they looked as if they had been hurriedly dipped as the varnish had runs in almost every chisel; also noted that some of the tips of the chisels had varnish drips on them. They did come useable ie sharp but I felt the need to remove the varnish drips first from some of the chisels.

Chisel sizes were pretty good to what they were supposed to be considering these are hand made at a forge; I have given the sizes here of what they are sold at and what they actually are

Sold at actually are

3mm 3mm

6mm 5.95mm

9mm 8.93mm

12mm 11.81mm

15mm 14.72mm

18mm 17.81mm

24mm 23.86mm

30mm 29.93mm

36mm 35.80mm

42mm 41.71mm

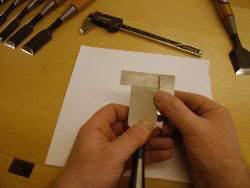

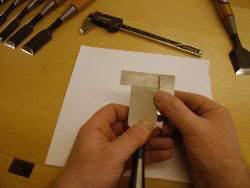

I inspected the tips of them with my little engineers square and only the 42mm and 30mm showed to be slightly out, the rest were pretty good; I couldn’t see light coming through when held under my magnifying lamp.

I have a Tormek but the jigs I have for it don’t allow me to hold the chisels for an accurate grind, they might have a jig for it but I don’t have it, the short length of the body of the chisel didn’t allow the chisel jig to support it well enough to sharpen.

I then turned to the scary sharp method; for those who don’t know what this is, basically its wet and dry paper ranging from 250grit through to 1000 grit glued onto a dead flat surface ie glass, the back of the chisel is then flattened then turned to do the bevel edge. I did the bevel edge at 30°. I usually finish my chisels with some 3000 grit diamond paste then a final rub on A4 paper; I’ve noticed this produces an exceptional finish. Because the backs of Japanese chisels are hollowed it only takes a few minutes on each grit to get good results I have done the chisel on the left in the photo but haven’t touched the one on the right yet, the chisel on the right you can clearly see the different laminations. The struggled to get a great picture of the sharpened one as the mirror face kept bouncing the flash of the camera.

After sharpening I tested with a few hairs on the arm; result ‘scary sharp’. I then put them to the test by cutting some dovetails in Ash, something I rarely do as I have a jig for this but I wanted to do this review with some step by step pictures.

End results; very good I gave them some light taps with the mallet then some fairly hefty whacks, nice clean cuts and no chips at the tips, I continued to cut the rest of the dovetails and the chisels were still as sharp; my hairy arms or should I say not so hairy arms will testify to that.

I am now a convert to Japanese tools, there saws and chisels are really excellent.

In my opinion this set of ten represents excellent value for money and a cheap intro into Japanese chisels; I hope this was of help to anyone considering these

Ian

Japanese chisels have been around for centuries, their laminating process used in their samurai swords have been adopted into their chisels; there laminating process seems to combine great strength with a very hard long lasting edge.

The chisels I have reviewed here are the traditional butt chisels or Oire-Nomi, I purchased these from Tilgear with the brand Aka-Kashi labelled on them. Considering the prices of other oriental chisels I’ve seen; priced at £95 these are probably aimed at the introductory side of the market.

They come individually wrapped in polythene envelopes with plastic tip protectors; the handles are red ash with a heavy coat of varnish, they looked as if they had been hurriedly dipped as the varnish had runs in almost every chisel; also noted that some of the tips of the chisels had varnish drips on them. They did come useable ie sharp but I felt the need to remove the varnish drips first from some of the chisels.

Chisel sizes were pretty good to what they were supposed to be considering these are hand made at a forge; I have given the sizes here of what they are sold at and what they actually are

Sold at actually are

3mm 3mm

6mm 5.95mm

9mm 8.93mm

12mm 11.81mm

15mm 14.72mm

18mm 17.81mm

24mm 23.86mm

30mm 29.93mm

36mm 35.80mm

42mm 41.71mm

I inspected the tips of them with my little engineers square and only the 42mm and 30mm showed to be slightly out, the rest were pretty good; I couldn’t see light coming through when held under my magnifying lamp.

I have a Tormek but the jigs I have for it don’t allow me to hold the chisels for an accurate grind, they might have a jig for it but I don’t have it, the short length of the body of the chisel didn’t allow the chisel jig to support it well enough to sharpen.

I then turned to the scary sharp method; for those who don’t know what this is, basically its wet and dry paper ranging from 250grit through to 1000 grit glued onto a dead flat surface ie glass, the back of the chisel is then flattened then turned to do the bevel edge. I did the bevel edge at 30°. I usually finish my chisels with some 3000 grit diamond paste then a final rub on A4 paper; I’ve noticed this produces an exceptional finish. Because the backs of Japanese chisels are hollowed it only takes a few minutes on each grit to get good results I have done the chisel on the left in the photo but haven’t touched the one on the right yet, the chisel on the right you can clearly see the different laminations. The struggled to get a great picture of the sharpened one as the mirror face kept bouncing the flash of the camera.

After sharpening I tested with a few hairs on the arm; result ‘scary sharp’. I then put them to the test by cutting some dovetails in Ash, something I rarely do as I have a jig for this but I wanted to do this review with some step by step pictures.

End results; very good I gave them some light taps with the mallet then some fairly hefty whacks, nice clean cuts and no chips at the tips, I continued to cut the rest of the dovetails and the chisels were still as sharp; my hairy arms or should I say not so hairy arms will testify to that.

I am now a convert to Japanese tools, there saws and chisels are really excellent.

In my opinion this set of ten represents excellent value for money and a cheap intro into Japanese chisels; I hope this was of help to anyone considering these

Ian