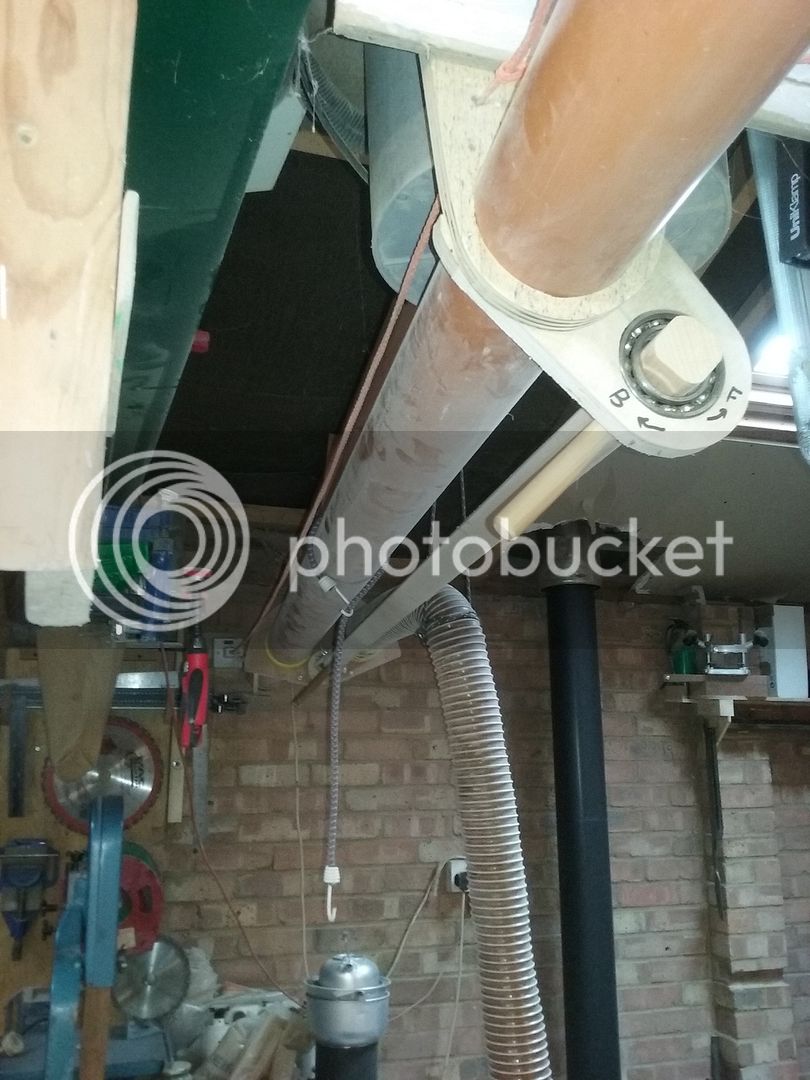

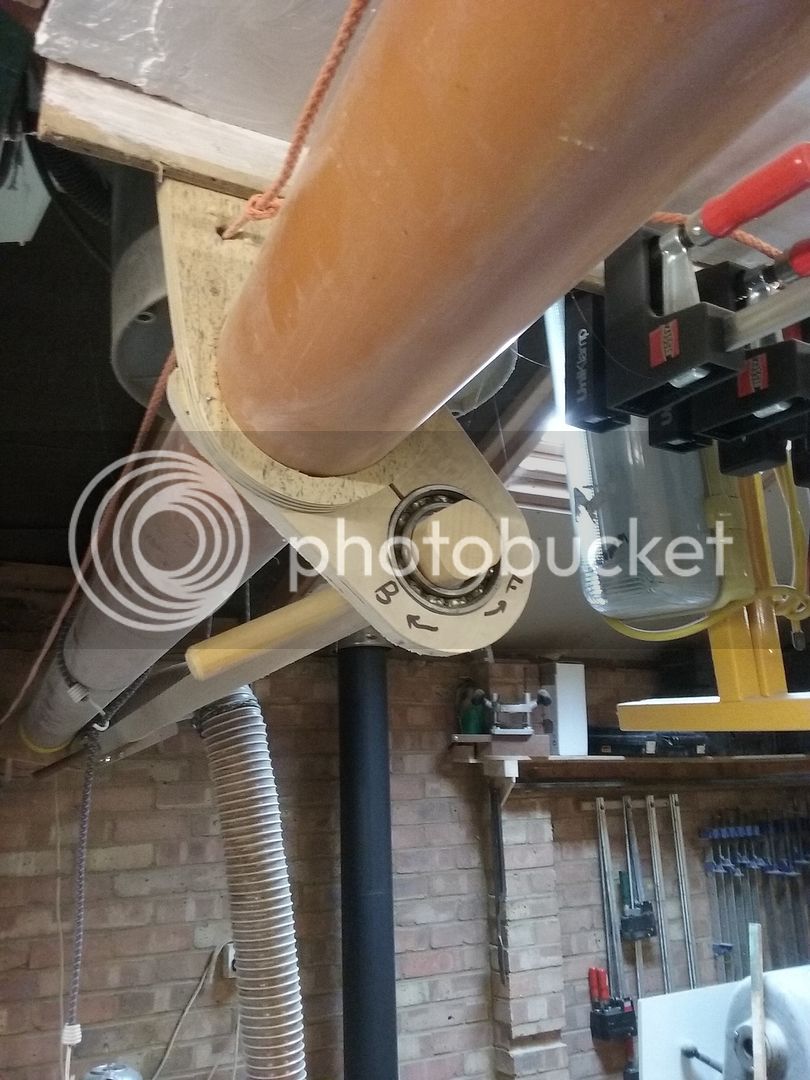

The new dust extraction system is finally up and running, woohoo.

Now it sucks better than a lady of disrepute in a particularly shady dock like boaty mc boat face kind of area!

Cyclone is performing brilliantly, there's nothing in the collection bags and I've just done a lot of thicknessing.

Thoroughly chuffed with it after all the researching time it took to put it together.

If anyone's interested in knowing more then ask away and you shall receive...

(Warning you respond at your own risk, I don't accept responsibility by boredom or drowsiness caused by my excessively detailed responses)

Now it sucks better than a lady of disrepute in a particularly shady dock like boaty mc boat face kind of area!

Cyclone is performing brilliantly, there's nothing in the collection bags and I've just done a lot of thicknessing.

Thoroughly chuffed with it after all the researching time it took to put it together.

If anyone's interested in knowing more then ask away and you shall receive...

(Warning you respond at your own risk, I don't accept responsibility by boredom or drowsiness caused by my excessively detailed responses)