Hello OscarG,

This is my first ever post so here goes…

AJB temple and custard have pretty much already said what I was going to say, but I’ll see if I can add any helpful information.

White ash, presumably you’re referring to American white ash, is usually a pleasure to work with and responds well to both machining and hand work. I’ve built two shaker tables and some other items from it and haven’t experienced any problems.

If your Bandsaw is struggling, I suspect it’s because you have a blade fitted which has too many teeth for the 45mm thickness you’re cutting. I think there’s a rough rule of having only 2-3 teeth in the timber at once, although I can’t remember exactly. Too many teeth in the timber at once means the sawdust isn’t cleared effectively and you end up with burn marks and a slow cut. This is particularly true of smaller benchtop bandsaws.

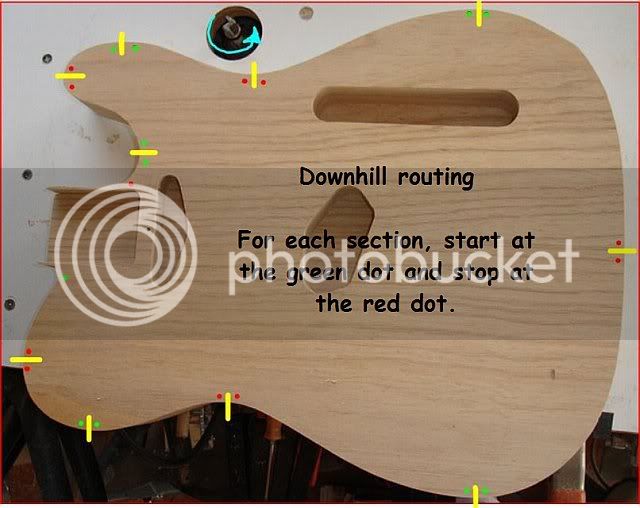

As for your issue with the router table, it almost certainly sounds like you’re feeding the work piece in the wrong direction. You should always feed against the rotation of the router bit, whether using a handheld router or table mounted. For a table mounted router, this transpires to feeding the work piece from right to left for external cuts and left to right for internal. If you feed in the wrong direction, which is referred to as a ‘climb cut’, the bit grabs the work piece and shoots it across the workshop (something which one usually only makes the mistake of trying once…). For handheld routing, a climb cut can result in the router ‘running away’ from you if the work piece is properly clamped.

If you’ve got a sharp bit and feed in the correct direction you should be fine. Your 1mm projection from the template is spot on. Just watch out for any areas where you have to rout against the grain – either take really light cuts rather than trying to take it to the template in one pass, or get another router bit with the bearing on the other end and flip the work piece the other way up, that way you end up routing with the grain again.

Hope some of that is useful. If you’re concerned about safety, it might be a good idea to get a dvd, as others have mentioned, or at least a book on the subject. There’s also a few good free online videos about, but also sadly a great number of clowns on youtube who show dangerous practises. I learnt a lot from ‘The Wood Whisperer’ when I first started out (I may be ridiculed for recommending him, I’ve seen a few comments around the forum saying he’s a bit annoying..). Do note a lot of the online stuff is American, which doesn’t always translate well to what goes on over here e.g. don’t go to an English timber yard and ask for ‘four quarter’ thickness… they thought I was a bafoon.