Hi DW as promised I took some pics of the Axminster mitre trimmer and 'cut length attachments'.

The attachments are pretty simple and cost £23 Like most things once you have seen something 'in the flesh' you could easily get some metal angle and a piece of wood and knock your own up in half an hour :?

The pull (or push) handle is removable (good safety feature). When the unit arrives it comes with a WARNING piece of cardboard, I've kept mine and I leave it in place when not in use.

As you can see in the pic I have mounted the mitre trimmer to the top of one of my rolling work stations so it is always out and I have found I use it quite a lot (I make a lot of boxes).

The trimmer is just that - i.e. it is not a mitre cutter (unless its very small beading) I usually cut the mitres to within 1 or 2mm and then slice off minute slithers of wood till I get to the mark.

The 'slicing' is very satisfying (the same feeling when your plane is newly sharpened and skims off wafer thin amounts of wood) 8)

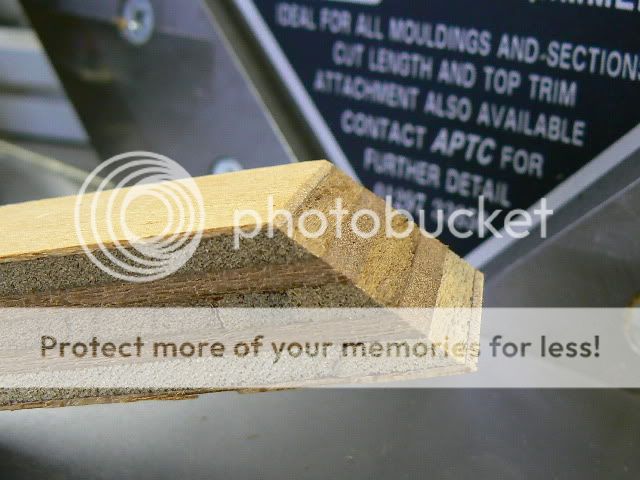

I use mine to cut 90 degrees accurately as well as mitres, here is a piece of ply cut on the trimmer, the picture doesn't do justice to the mirror finish the trimmer gives to the wood

All in all I am very happy with it

Regards

john