A long overdue update (mostly because it's taken until now to get the job done).

I finished planking the logs, mostly into 3/4" and 1" thicknesses, and a few 2 1/2" square. All had the ends sealed with a generous helping of PVA glue:

Lacking anywhere suitable to store the planks, I bought one of these garden storage units (by the time I'd finished building it the site foreman had gotten bored, and she'd padded off in search of a bottle):

I stickered the planks as best I could:

Looking further into drying green timber, it seems there's an argument that air dried wood will never reach a low enough moisture content for use as indoor furniture (i.e. it needs to be kiln dried). A bit of searching yielded this interesting page:

http://www.popularwoodworking.com/projects/solar-kiln

In a nutshell, it uses the sun's energy to heat the inside of a cabinet, and a fan to force the warm air through the stack of green wood. At night, the fan shuts down, and the moisture in the air condenses onto the wood; thus stopping the outer surface drying too quickly.

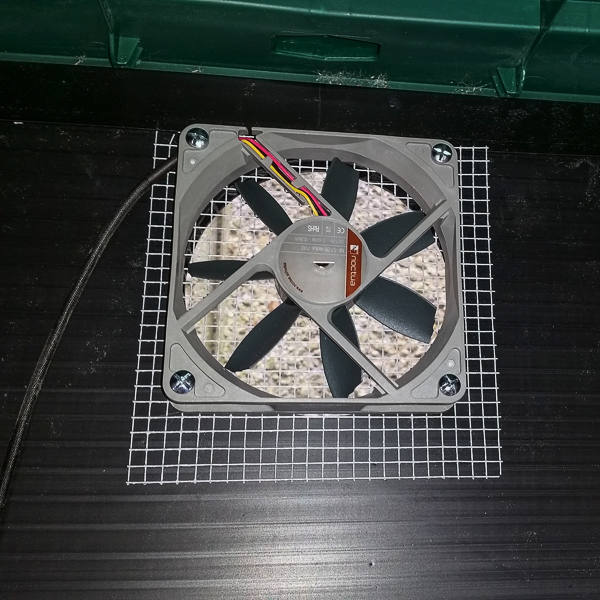

The storage unit I'd built is south facing, so I've decided to go for a (very) poor man's version. I bought a 12v 5w solar panel for £20 from FleaBay, and got a 120mm computer case fan with a very low current requirement.

I cut a suitable hole in the top middle of the back board of the storage unit, then added the fan, with some 6mm mesh to keep vermin out:

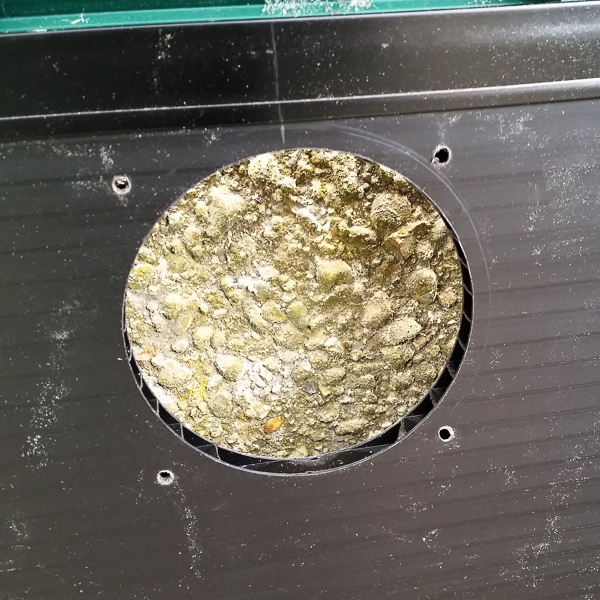

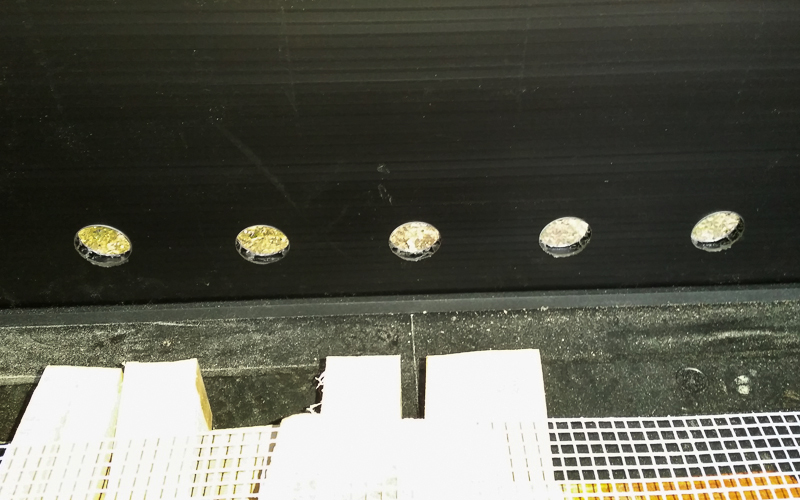

I then cut a series of holes near the bottom of the back board, roughly equating to the area of the 120mm hole, then covered that in mesh too:

Finally (and I need a larger board) I put a board over the stack, such that air being pulled in by the fan would have to go through the stack to exit the storage unit:

The last few days have been quite overcast, but the fan's been whirring away slowly. This morning was pretty cold outside, but the dark green lid of the storage unit was warm to the touch (due to the little bit of sunlight we'd had), and when I lifted the lid the air inside was obviously warmer than outside. I suppose therefore it's possible that this cobbled together project may work.

If I had time (which I don't) and a Raspberry Pi, a bunch of sensors and a moisture meter (none of which I have), I'd be logging the inside & outside temperatures, humidity, and board moisture content. I guess I'll just have to stump up for a moisture meter at some point and see how the boards are doing. Any recommendations?