I made it about 30 minutes in the “workshop” before “rain stopped play”. So I’ve come in to chat to you lot and tried a bit of applied thinking, in the hope that the thinking brain has come back.

I measured how much of the top of the box had been Mullered, 3/8” and marked a line around to cut/plane to, I also thought I'd better move a nail!;

I’d been thinking over suggestions on how to do this and decided as it was quite a lot of wood that I’d need to remove at the corners, so I thunked that I’d cut them with the saw, as I wasn’t quite so crap at that. Then I put some battens on to act as a guide;

Then I started cutting, the first corner I angled the saw down and cut, reasonably smoothly;

….and the next corner I cut up, trying to vary the angle, but generally using a low angle (30-45ish degrees); this went juddery or smoothly depending, I think I started realising why (we’ll come to that later);

I noticed afterward, that even with the guide, I still wasn’t getting a straight/square cut;

There’s a lot more to using these saws than I’d thought!!

One side was fine;

but the corresponding end was still a bit on the p**s. Luckily, the guide battens meant the cut went into the bit I didn’t want this time. This was when rain occurred, so I came in to drink my tea on the sofa instead of the garden chair (need to get some Hob-nobs). I then tried some thinking, which has started to induce a head-ache.

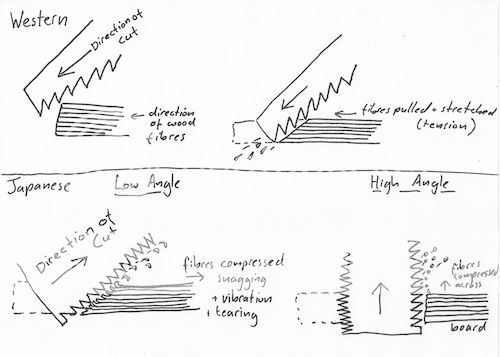

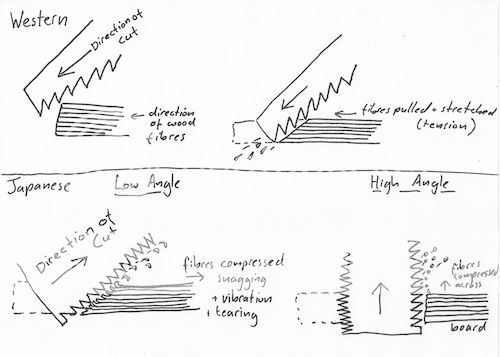

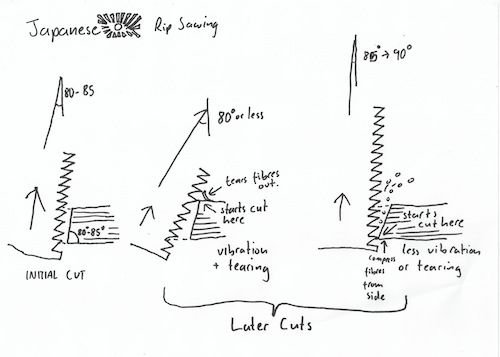

I was thinking about the difference between a Japanese saw and a Western saw, following yesterdays revelation. It’s not just that the blade is thinner, and being tensioned/pulled, instead of compressed/pushed. The way of hitting the grain is different too, this is regarding Rip Sawing anyway, the brain is not capable of thinking about cross-cut yet;

..not sure how clear the diagram is, but hopefully you get the drift. The angle of attack on the fibres is different, which is why I think they need to be used with a very high angle, approaching 90 degrees. The instructions I’ve read from older Japanese types is to have the board low, effectively you stand on it, and you rip upwards, with the blade slightly angled toward you. You need to cut the fibres at nearly 90 degrees to the direction they go in. With Western saws, the fibres are stretched, so you can use a lower angle.

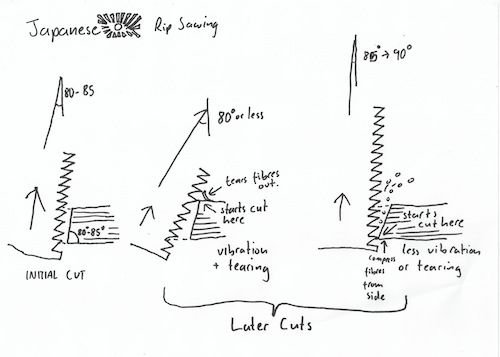

I also noticed that as I ripped, the saw could judder or be fairly smooth, I think this was to do with the angle at which I started each cut and this may have been affected by holding the saw at a lower angle (trying to get the cut as straight as I could). Once I started cutting, depending on the angle of the saw, I was starting each cut either on the lower side or the higher side of the board;

Not sure how clear the diagram is, but it’s trying to show what I think was happening. If correct, I need to “lift” the saw a little at the start of each cut stroke to ensure the teeth start on the lower fibres/face and then lower the angle a tad each stroke. Hopefully an elderly Japanese Shokunin will chip in to advise.