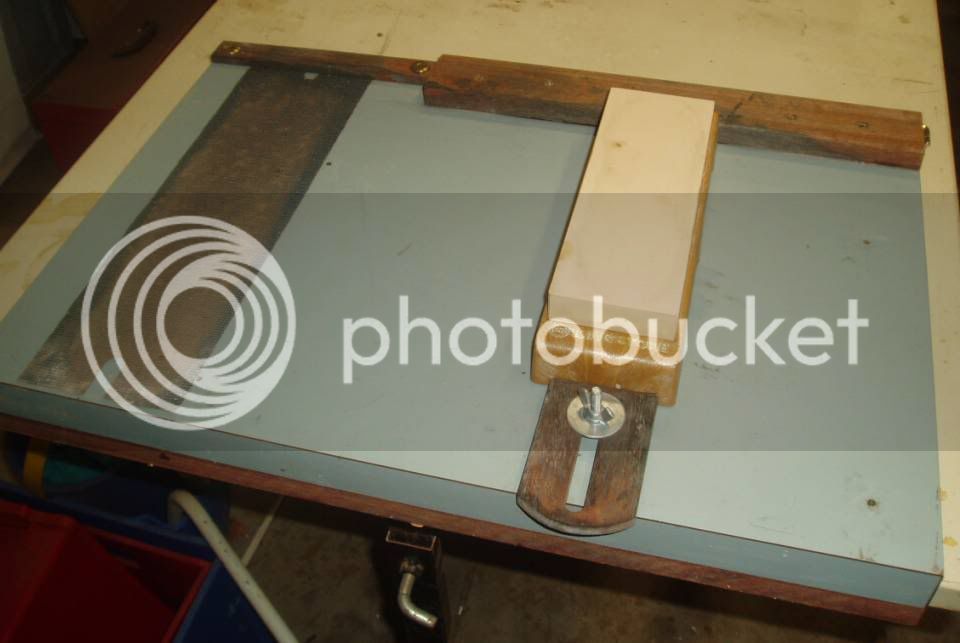

Here are a few pictures of a waterstone/sharpening board I made. I also use the drywall mesh for flattening my stones.

I used to sharpen my chisels and plane irons with the waterstone just sitting on the bench and I would flatten the stones using wet or dry sandpaper stuck to a plate of float glass. I have found that this board makes things a lot easier.

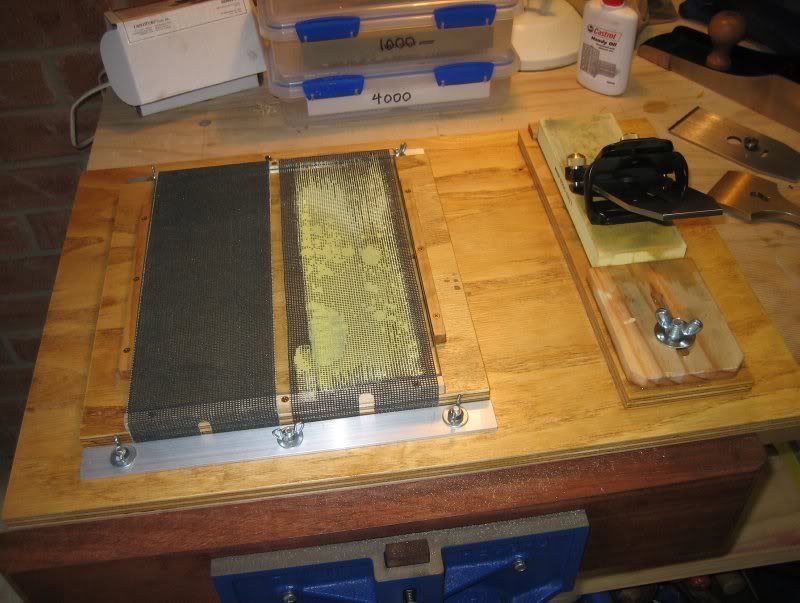

I have used 16mm ply to make the board and the 'islands' that the stone and the glass/flattening media sit upon.

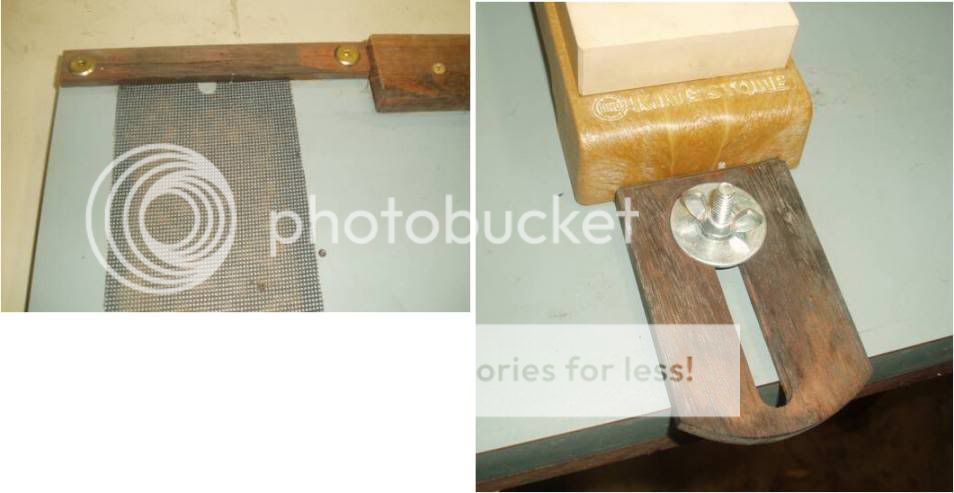

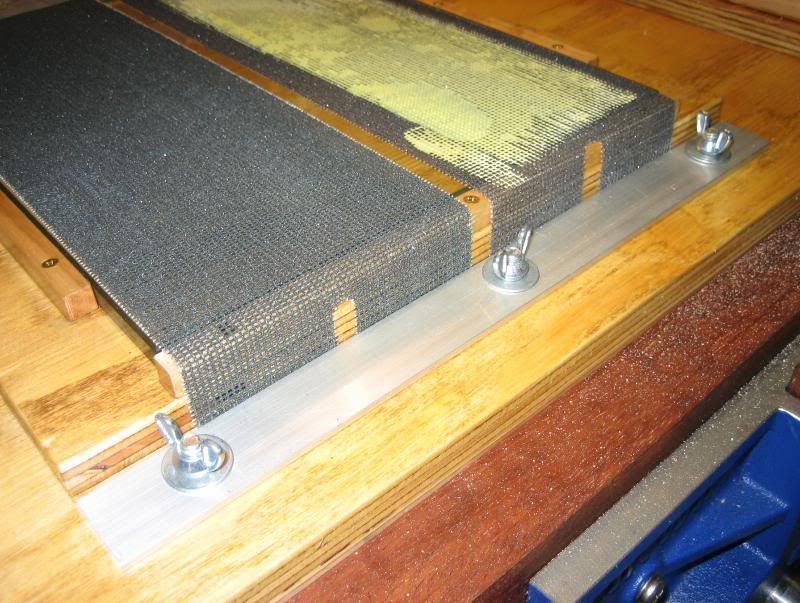

To provide a flat base for flattening the waterstones I have a piece of 10mm thick float glass 230mm x 280mm. This is held in place on the board by 4 short lengths of 9mm square tassie oak that I have screwed in place. I used 9mm square tassie oak so that the top of the tassie oak sat below the top of the float glass. The clamps that I use to hold the abrasive media in place are made of 3mm x 25mm aluminium flat bar and 1/4 inch bolts/wingnuts.

The idea behind sitting the float glass on a kind of 'island' is that is raises the height of the top of the glass above that of the 1/4-inch bolts and the wingnuts that I use to clamp the abrasive in place. I can therefore overshoot the edge of the glass with a waterstone and not have to worry about hitting the end of a bolt. The 'island' also raises the glass up away from any slurry/water that spills over from the waterstone during sharpening.

I chose the dimensions of the piece of glass based on the dimensions of a sheet of sandpaper. Wet and dry sandpaper is also 230mm x 280mm so I can still choose to use wet and dry sandpaper stuck to glass for flattening or lapping if I wish. If I do this then the clamps on the board are not used but the piece of glass is still held securely on the board.

The abrasive media that you can see clamped in place on the board is the plasterboard/drywall mesh that we have been talking about earlier in this thread. It measures 108mm wide by 375mm long. There are 2 strips of it shown clamped to the board in the pictures, one is 220 grit and the other is 150 grit. I have a 220 grit waterstone and so I got the 150 grit mesh for when I need to flatten it.

You can see in the pictures above that the waterstone itself is also sitting up on a little island. This serves the purpose of raising the top of the stone higher up off the top of my bench which in turn gives me more clearance when flattening the backs of chisels and plane irons. I have placed the stone on the right side of my board (when you face the bench) because when I flatten chisels etc. I hold them out the right side of the stone. If I had placed the waterstone on the other side of my waterstone board the glass and abrasive media that I use for flattening stones would be in the way.

Similar to the flattening area of the board, having the waterstone raised up on a little island keeps it clear of any slurry or dirty water etc. that spills over from the waterstone flattening process.

I have used a 3/8-inch bolt/wingnut to make the clamp for the waterstone. I put the clamp so that is closest to me when I stand at the bench because when I sharpen I have the blade/honing guide oriented as shown in the pictures. With the clamp oriented as shown, if I overshoot the waterstone during the sharpening process I will hit the bolt/wingnut with the roller on my honing guide and not with a tip of a blade.

Finally, I have screwed a batten to the base of the board so that I can keep it steady on my bench by clamping it in my vice. The whole thing has been sealed with a couple of coats of polyurethane.