A

Anonymous

Guest

Hi again Andy

This scenario has got me thinking its an interesting project.

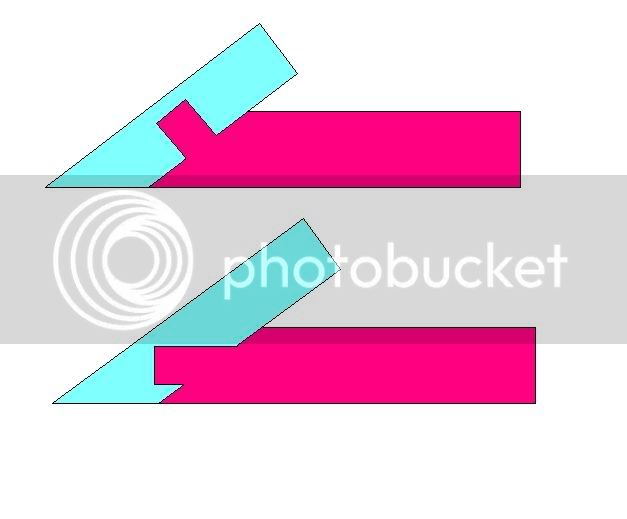

If you had a large sheet of the birch ply (at least 32 inches by 40 inches), and set out a "7" with the point to the right hand top corner, then a mirror image of the "7" set out with its point in the top left corner, so that when you look at the layed out sheet you have more or less a equilatteral triangle with its point toward you, then if you machined your housings across them together in your desired position's, then they would line up for assembly the same way they were machined. BUT thered be slightly more wastage, and youd need to use one of those straight edges to work along? I'd still be inclined to use a jig with a step locating device-at least then the off cut's would be free of housings!! Birch ply always comes in useful for odd jigs and stuff anyway..... :wink: If I set them out that way I'd use 2 complete one piece "7's" make about 1/8 th of an inch oversize, for each "hand". Like you say you can get best side out both sides if you do this way. Locate together with a few dowels or biscuit's to stop them slipping, glue up, then trim using a nice template finished to a high quality (attach the template with screws into a spot that will later be housed out?) and then machine the housings. No need for a M&T in that scenario 8) Hand cut the mortices (or use a router jig-you seem to have more experience than I do with the routers). Plane up the cross strut's etc, you've already got the backrest lamination sorted. Go for it! I could see this being a real nice job. The challenge wood be to get the same precision and crisp finish. My boys tripp trap gets hammered 3 times a day for about 3 or 4 years now and it still looks great (well when its free of pasta curry and peas etc :wink: )

What sort of colour/finish would you be considering?

Cheers Mr S

This scenario has got me thinking its an interesting project.

If you had a large sheet of the birch ply (at least 32 inches by 40 inches), and set out a "7" with the point to the right hand top corner, then a mirror image of the "7" set out with its point in the top left corner, so that when you look at the layed out sheet you have more or less a equilatteral triangle with its point toward you, then if you machined your housings across them together in your desired position's, then they would line up for assembly the same way they were machined. BUT thered be slightly more wastage, and youd need to use one of those straight edges to work along? I'd still be inclined to use a jig with a step locating device-at least then the off cut's would be free of housings!! Birch ply always comes in useful for odd jigs and stuff anyway..... :wink: If I set them out that way I'd use 2 complete one piece "7's" make about 1/8 th of an inch oversize, for each "hand". Like you say you can get best side out both sides if you do this way. Locate together with a few dowels or biscuit's to stop them slipping, glue up, then trim using a nice template finished to a high quality (attach the template with screws into a spot that will later be housed out?) and then machine the housings. No need for a M&T in that scenario 8) Hand cut the mortices (or use a router jig-you seem to have more experience than I do with the routers). Plane up the cross strut's etc, you've already got the backrest lamination sorted. Go for it! I could see this being a real nice job. The challenge wood be to get the same precision and crisp finish. My boys tripp trap gets hammered 3 times a day for about 3 or 4 years now and it still looks great (well when its free of pasta curry and peas etc :wink: )

What sort of colour/finish would you be considering?

Cheers Mr S