swagman

Established Member

Received this Hindustan from the u.k. Dimensions are 8" x 2 1/4" x 5/8". Out of flat on both major surfaces, and badly stained with iron oxide.

After flattening on 220 loose sic, followed by w & d up to 400 grt, the natural features within the stone become more noticeable.

The chisel shown was worked with a medium grit Norton Crystolon stone prior to the Hindustan stone. The Hindustan was 1st trialled using Honing Oil, but was rejected soon after due to the dulling effect it had on the cut of the stone. Using water as a stone lubricant was much more successful. Taking into account the rate of cut, and the size of the wire edge formed, my personal opinion is that this stones characteristics was comparable to a Mst Muller 8000 grit.

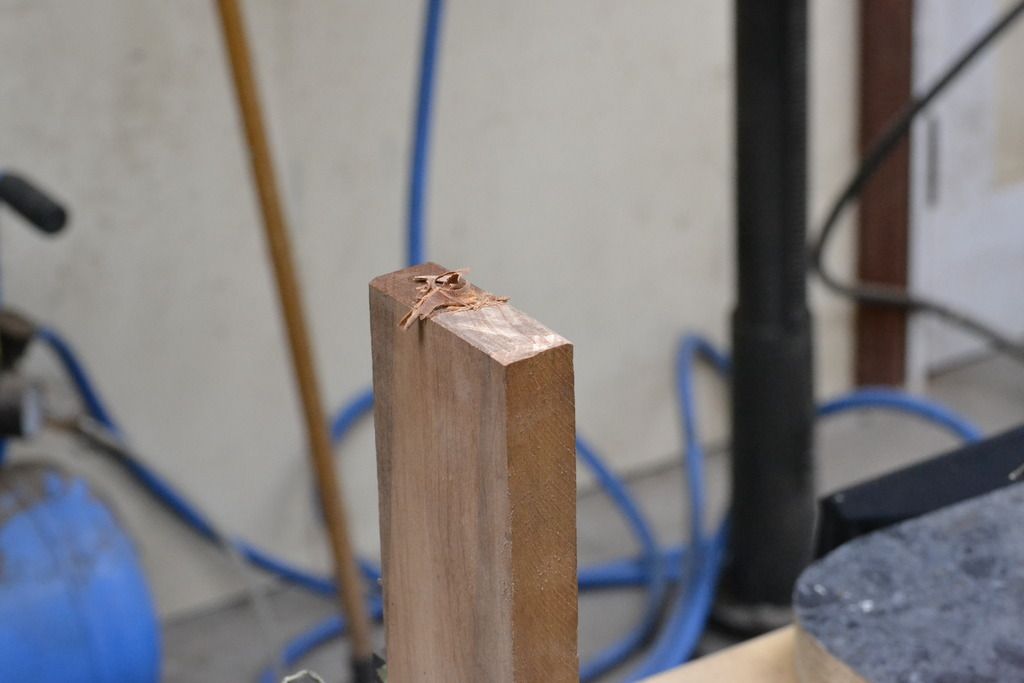

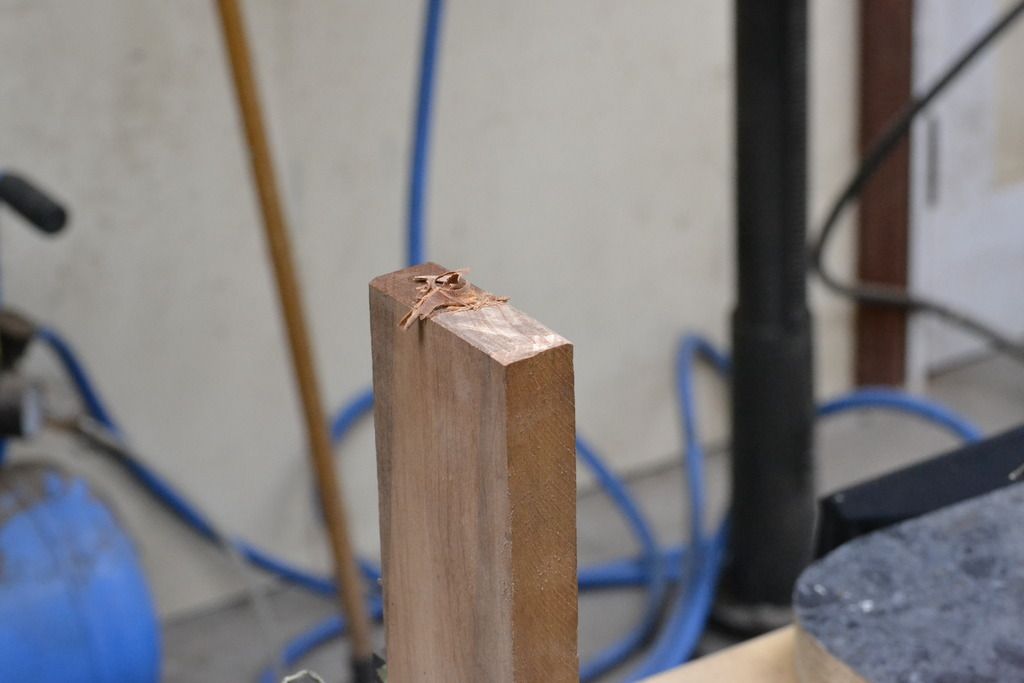

Testing the sharpness of cutting edge (straight from the stone). The cutting edge was good enough to cleanly slice through the end grain fibres, but slightly more effort was required, compared to that of another chisel, by the same maker, to the same bevel angle specs, but taken to a higher grit of 12000+ on my Welsh Llyn Idwall Grecian Hone.

Stewie;

After flattening on 220 loose sic, followed by w & d up to 400 grt, the natural features within the stone become more noticeable.

The chisel shown was worked with a medium grit Norton Crystolon stone prior to the Hindustan stone. The Hindustan was 1st trialled using Honing Oil, but was rejected soon after due to the dulling effect it had on the cut of the stone. Using water as a stone lubricant was much more successful. Taking into account the rate of cut, and the size of the wire edge formed, my personal opinion is that this stones characteristics was comparable to a Mst Muller 8000 grit.

Testing the sharpness of cutting edge (straight from the stone). The cutting edge was good enough to cleanly slice through the end grain fibres, but slightly more effort was required, compared to that of another chisel, by the same maker, to the same bevel angle specs, but taken to a higher grit of 12000+ on my Welsh Llyn Idwall Grecian Hone.

Stewie;