Simon_M":3howc8iz said:

Thanks for the info on how to make these. I particularly like segmented projects - I like woodturning segmented projects but I’m motivated to give it a go with these.

You're very welcome Simon

It was a fun project, from making the jigs to spraying, and I was very happy to see all the sides come together nicely when putting them together. The main thing for me was seeing our lass smile, made it all worth while

Simon_M":3howc8iz said:

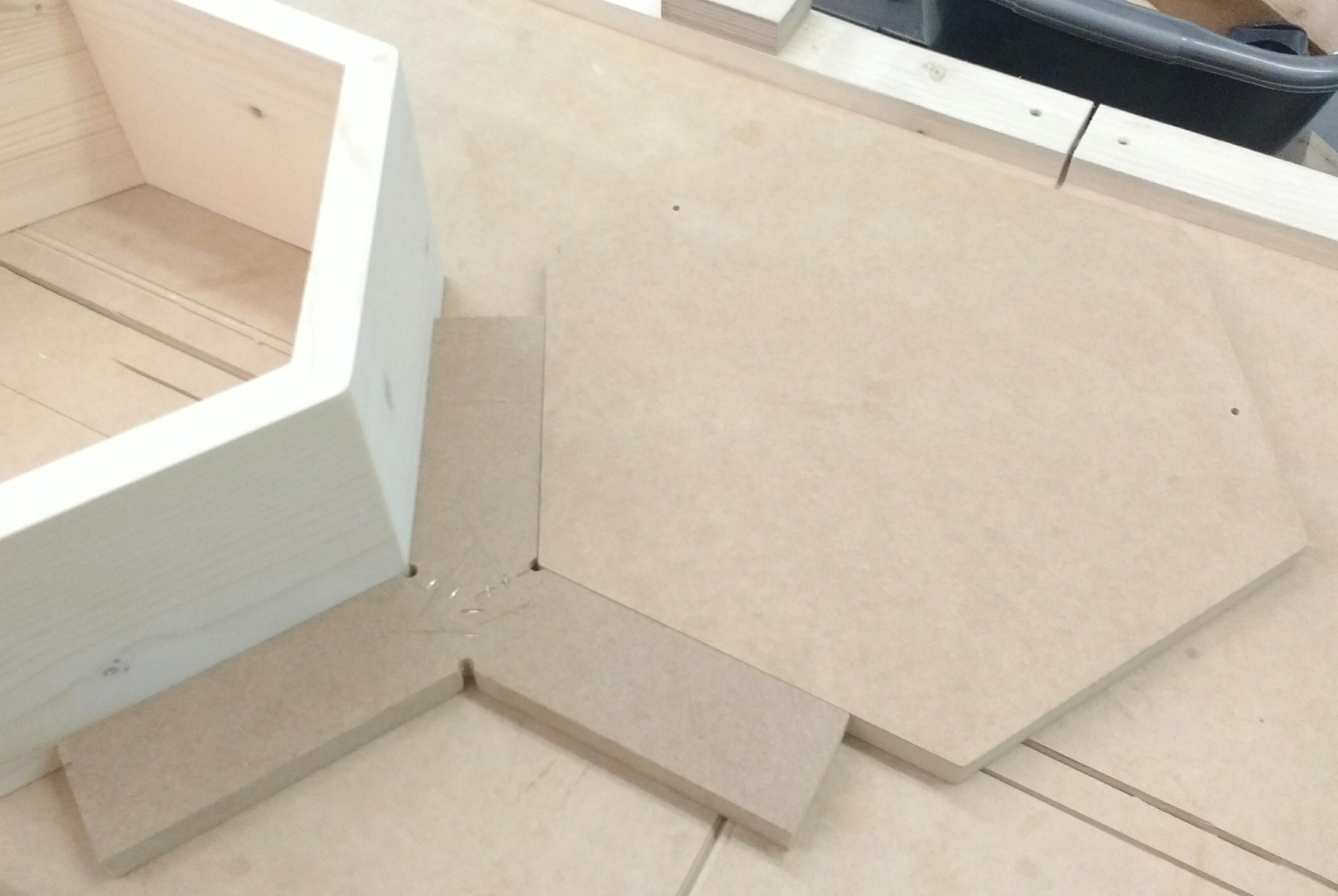

Perhaps the solution to making these, is to make them on more of an industrial scale e.g. why not make a hex that uses the complete length of an MDF board and then slice it up on the bandsaw?

The bottom line is that this is an Interesting topic for making at home for one’s own amusement/challenge. Thanks.

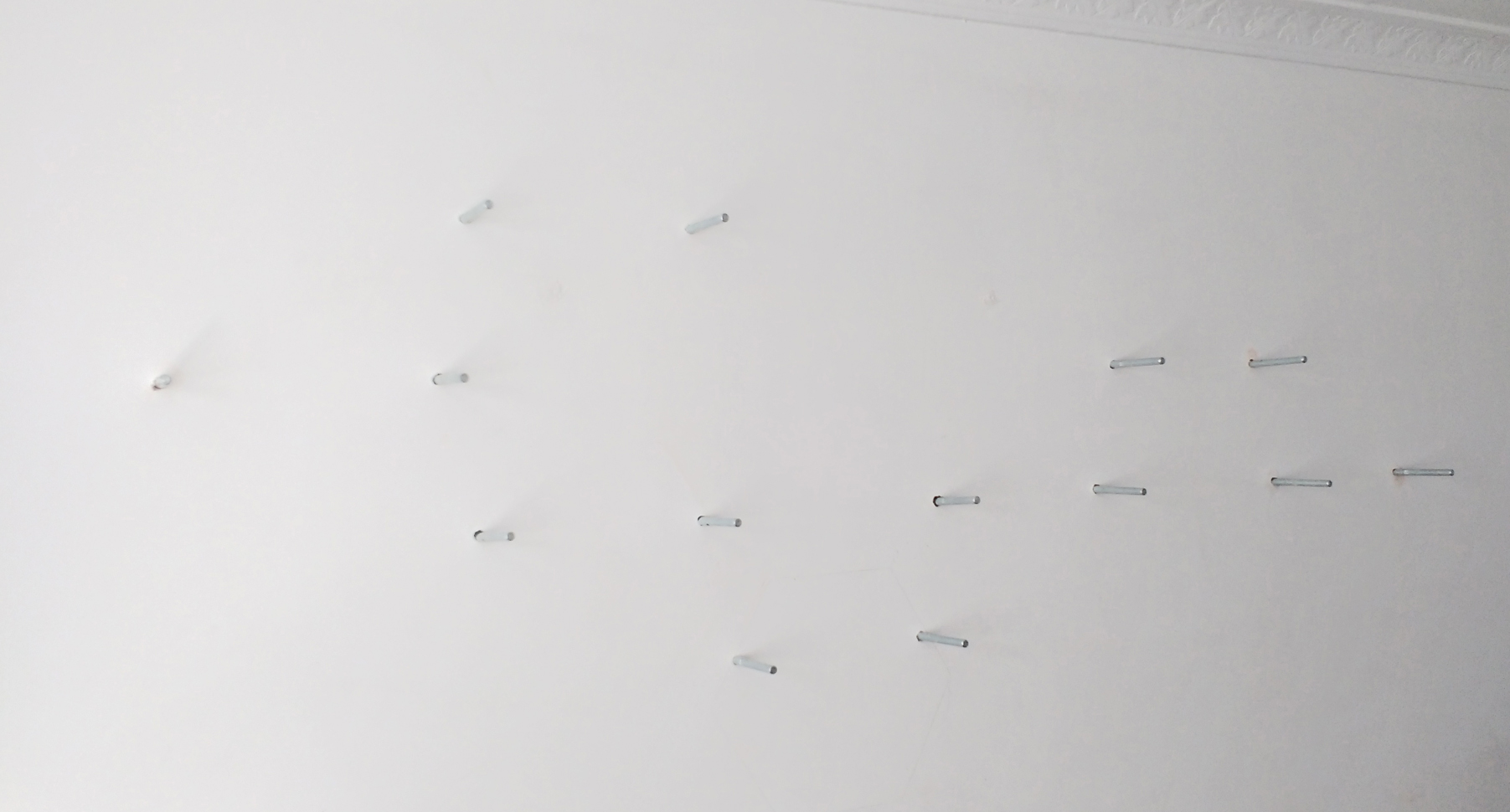

I don't make anything to sell anymore, tried it once, and as my accountant said, " You don't have a business, just a very expensive hobby"...I do have an order for five of the Hexagon boxes, but they'll be made as a gift. Although the person in question doesn't know that yet.

Interesting you mention MDF. I reckon if the local timber yard cut a sheet of 8 x 4 in to strips, leaving you to cut the segments, bevels and glue up, you could make 16 boxes. Personally, I'd be looking to sell an unfinished box for a tenner, and there's the problem. The buyer has to finish them, so if they buy seven boxes it'll cost them around £30.00 on spray paint plus £18.00 on brackets, and they still have to hang them. You'd have to sell them a spacer and template for hanging, may another tenner, but they'll be in for £130.00. I can't see many folk paying that when they have to put a few hours work in to it themselves, I might be wrong, but I think most would want to buy finished boxes and have them hung for that money.